Gas leakage detecting device and detecting method thereof

A gas leak detection, gas technology, applied in the measurement device, by detecting the appearance of fluid at the leak point, testing the fluid tightness, etc., can solve the problems of inapplicable detection, low helium leakage, and reduced sensitivity, etc., to achieve Effect of improving gas collection ability, improving detection efficiency, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

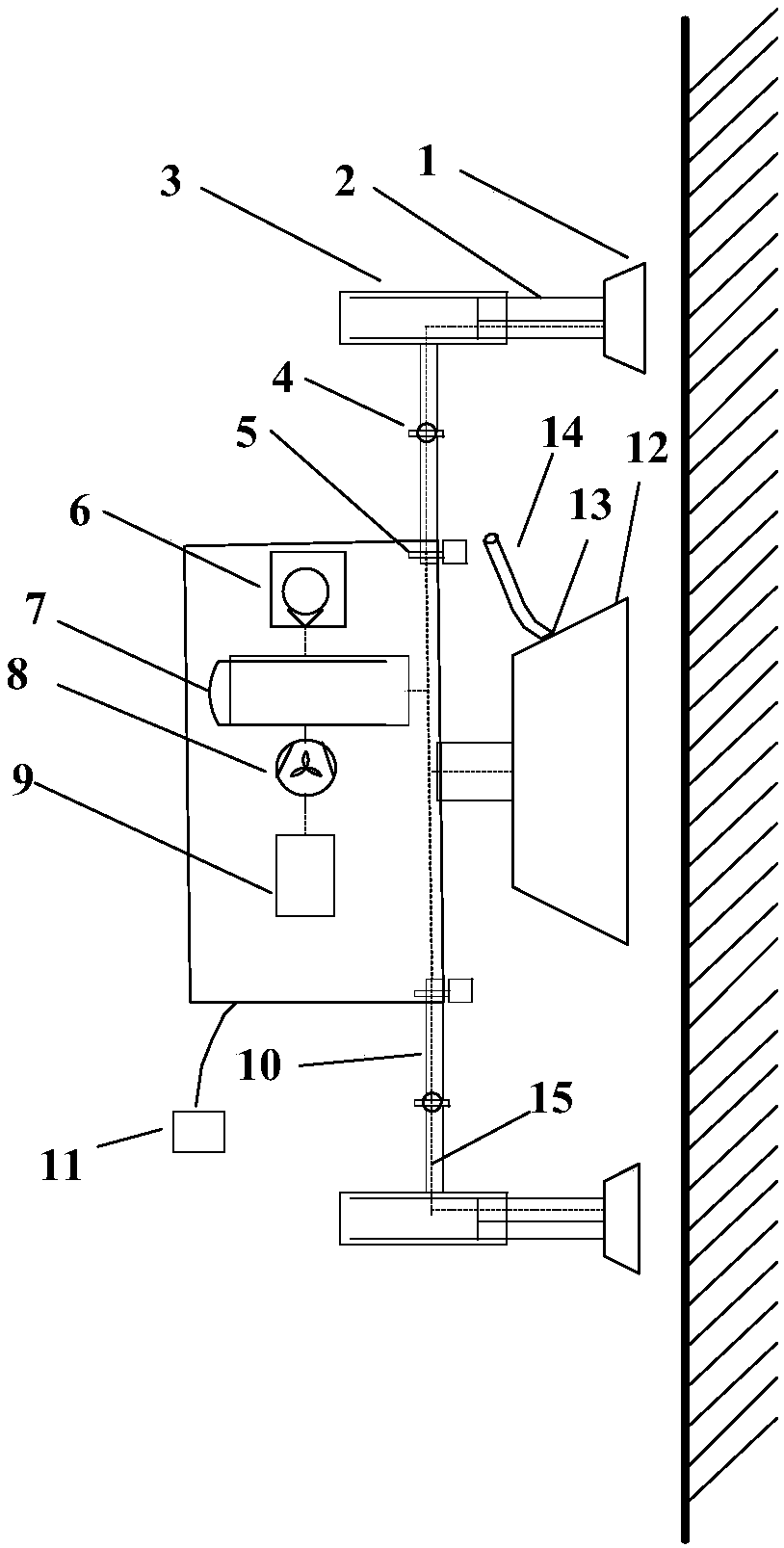

[0038] Embodiment 1: This embodiment provides a gas leak detection device, which uses the tracer gas method to quantify and locate a single leak point of the airship, and is powered by an external power supply 11. The detection device includes a detection component and a crawling positioning component;

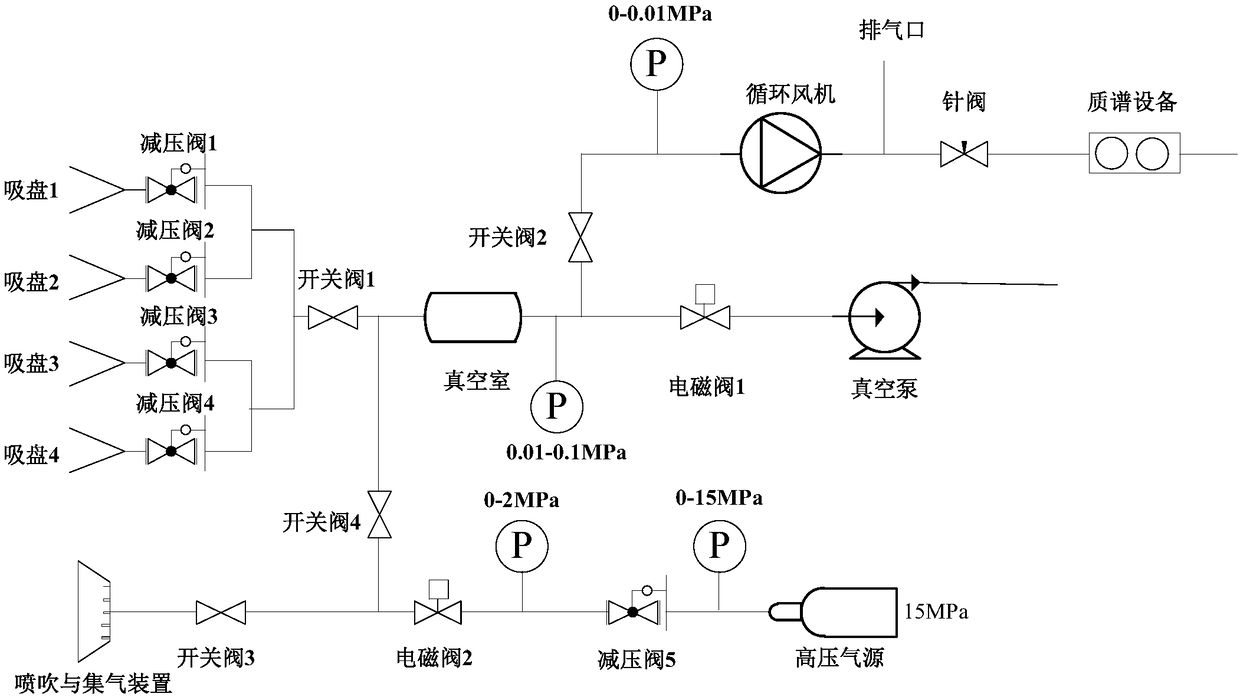

[0039] The detection component is used to detect airship skin defect gas leakage, including injection and gas collection unit 12, vacuum pump 6, vacuum chamber 7, circulation fan 8, mass spectrometry equipment 9, high-pressure gas source pipeline 14, gas collection pipe Road 15 and the control valve;

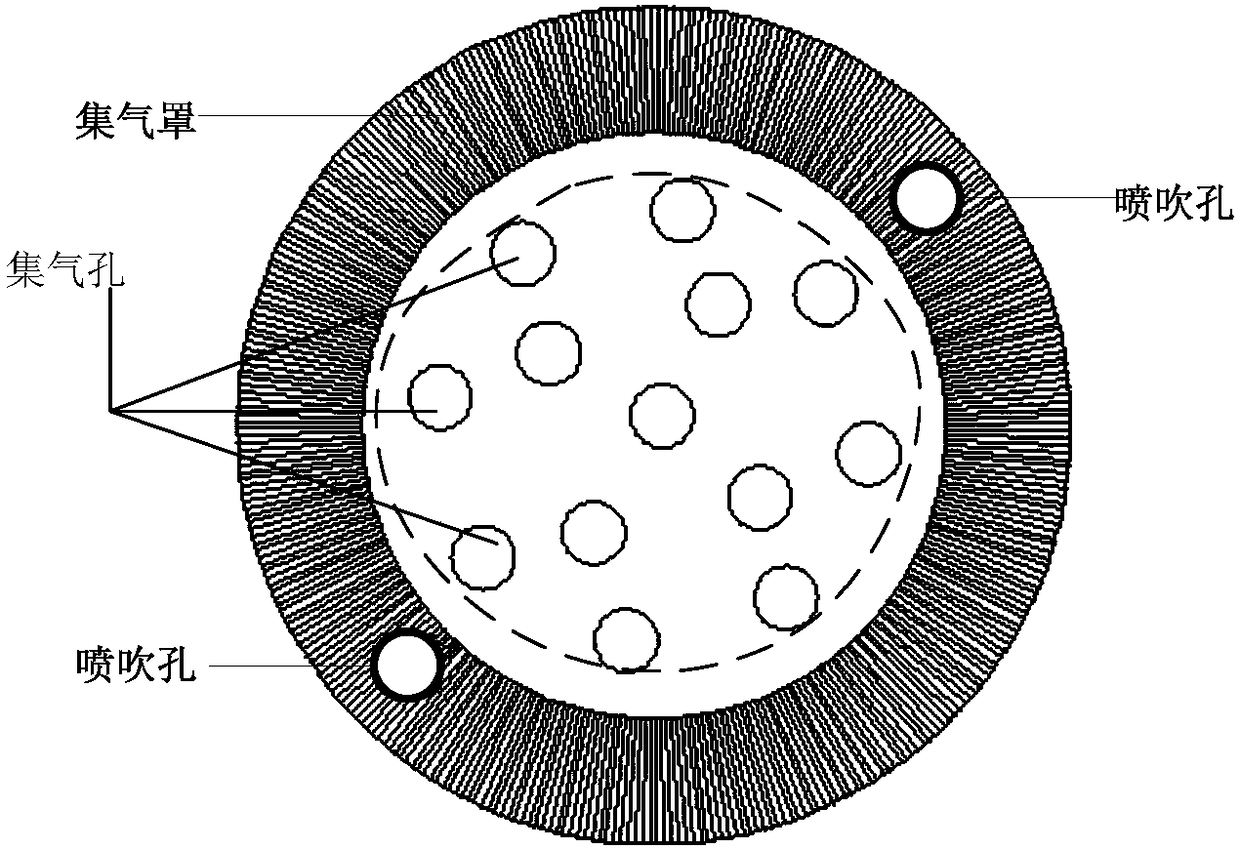

[0040] Wherein, the injection and gas collection unit 12 includes a gas collection hood and a high-pressure gas source; one end of the gas collection hood is provided with a gas collection hole for collecting gas, and the other end is connected to the inlet end of the vacuum chamber 7 through a switch valve IV, and the gas collected by the gas collection hole The gas enters the ...

Embodiment 2

[0048] Embodiment 2: This embodiment proposes a gas leakage detection device based on an adsorption crawling robot, and the detection components are the same as those in Embodiment 1. The automatic detection of airship skin defects is realized by using the adsorption robot. The adsorption robot has the functions of adsorption, walking and gas collection and identification, and meets the following requirements:

[0049] (1) Free movement function, which can move freely on the skin surface of the airship.

[0050] (2) Gas collection function. The robot suction cup has the function of negative pressure adsorption. At the same time, it is used as a gas collection device on the skin surface, combined with a non-contact injection and gas collection unit to realize rapid gas collection of portable mass spectrometry equipment.

[0051] (3) Curvature adaptability function. Due to the different curvature changes on the surface of the airship and the obstacles of prominent structural par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com