A Method for Coating Aging Failure Evaluation in Atmospheric Thin Liquid Film Environment

An evaluation method, thin liquid film technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

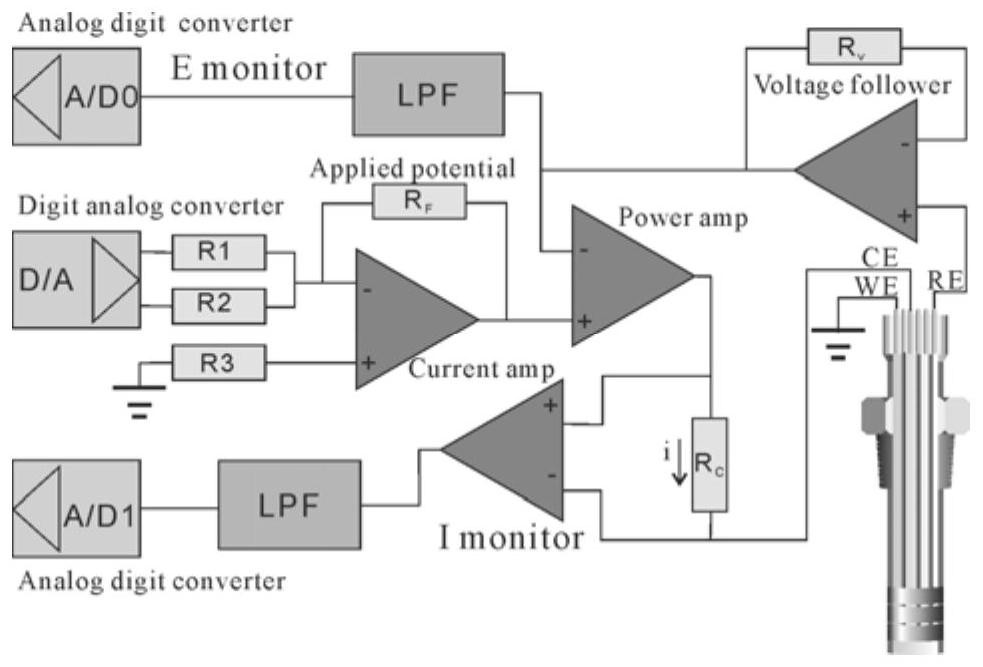

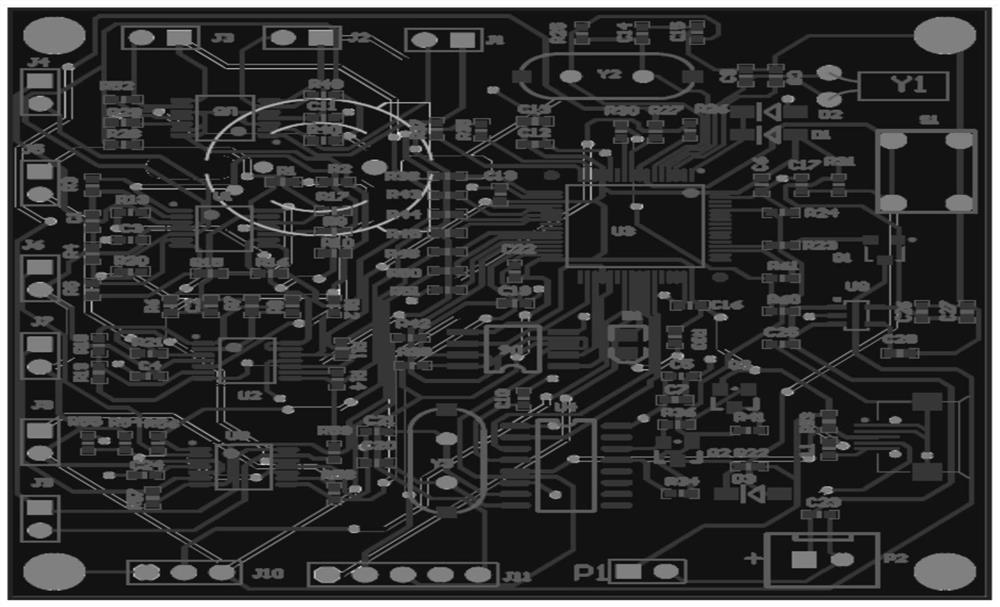

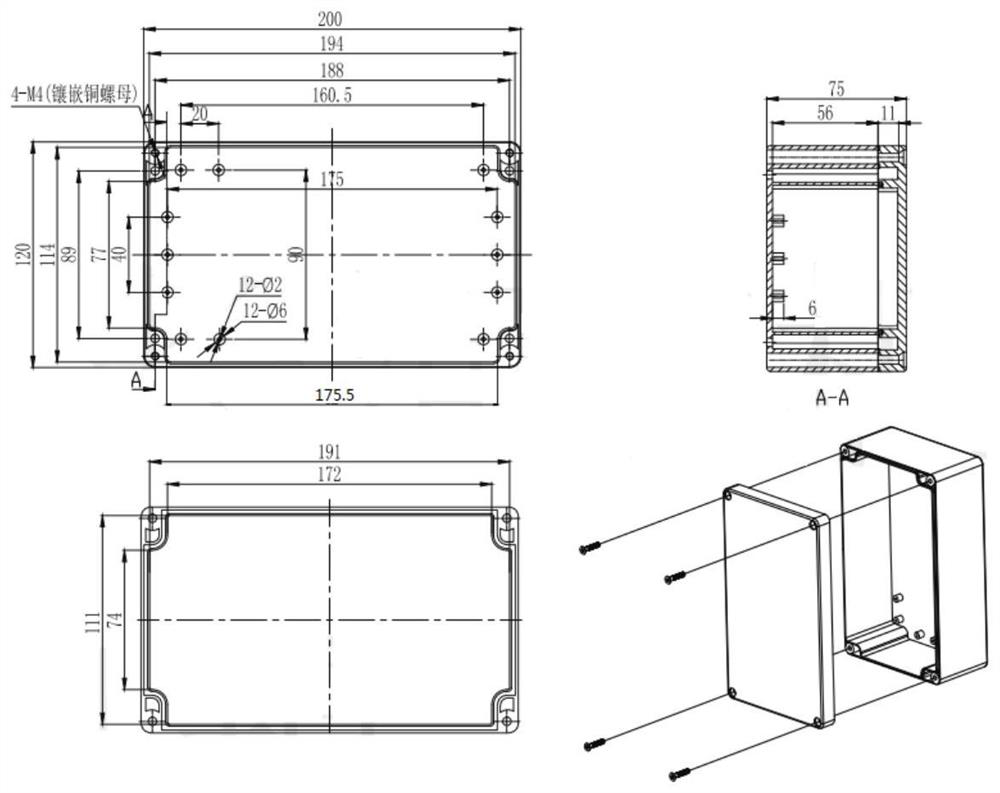

Method used

Image

Examples

Embodiment 1

[0038] In this case, the experimental verification is carried out according to the above probe design: using the above evaluation method, the prepared polyurethane coating PU, fluorine polyurethane coating F-PU, and acrylic polyurethane coating A-PU test samples are placed in the salt spray aging box, The neutral salt spray accelerated aging test of the coating is carried out. The test process uses a neutral NaCl solution with a pH of 7 and a mass fraction of 5.0% at 35°C. It uses intermittent spraying, 60min spraying, 60min intermittent, and the monitoring probe is connected to the detector. Impedance test. From Figure 5 From the EIS spectrum of the sensor test, the impedance of the three organic coatings in the early stage of aging is relatively large, all above 109Ohm·cm2, and the coating has a strong protective performance. With the extension of the salt spray acceleration time, the Nyquist arc of the coating gradually decreases. The impedance decreases 384h before the s...

Embodiment 2

[0040] This case is tested and verified according to the traditional three-electrode system soaked in electrolyte: Figure 6 It is the EIS spectrum of the coating tested by the traditional three-electrode system soaked in electrolyte in the laboratory, and Figure 5 The comparison of the coating impedance attenuation process of the medium probe test can be obtained. During the failure process of the three different organic coatings, in the first 384 hours, a large semi-circle arc appeared in the Nyquist spectrum, and the Bode The impedance in the low-frequency region in the figure is reduced to 106Ohm cm2. In order to further investigate the performance of the sensor in the test coating aging system, the Figure 6 The equivalent circuit in the medium is fitted to the EIS spectrum, and the curves of the resistance RCMS and capacitance CCMS of the coating / metal system obtained by the two methods are compared with the salt spray time: using Figure 6 (a) When fitting: RCMS=RC, C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com