Local electromagnetic field enhancement device for Raman spectrum characterization as well as preparation method, application and utilization method thereof

A technology of Raman spectroscopy and electromagnetic field, applied in the field of detection, can solve the problems that it is difficult to obtain the difference of single-molecule configuration and conformation, and it is difficult to obtain Raman scattering signals on the single-molecule scale, so as to overcome the difference of configuration and conformation, Effect of enhancing Raman scattering signal and preventing oxidation of silver layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

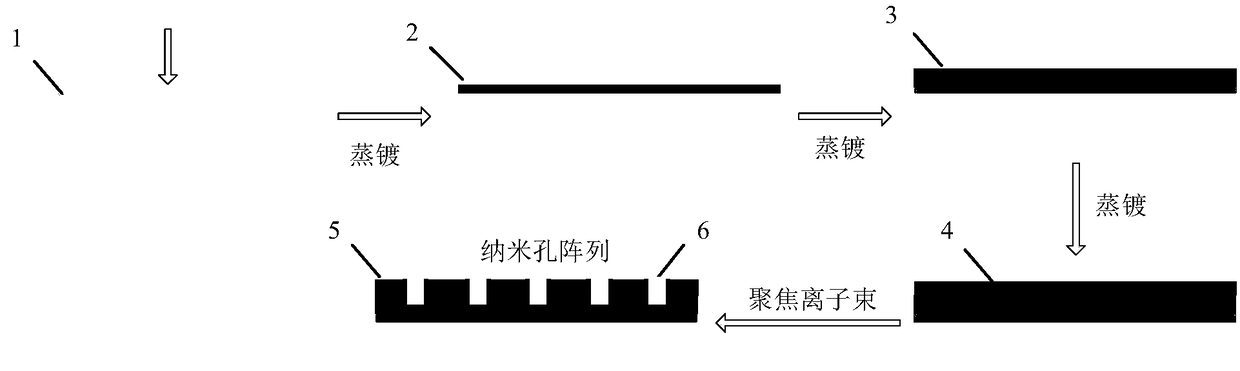

[0033] Fabrication of Localized Electromagnetic Field Enhanced Devices for Raman Spectroscopy Characterization

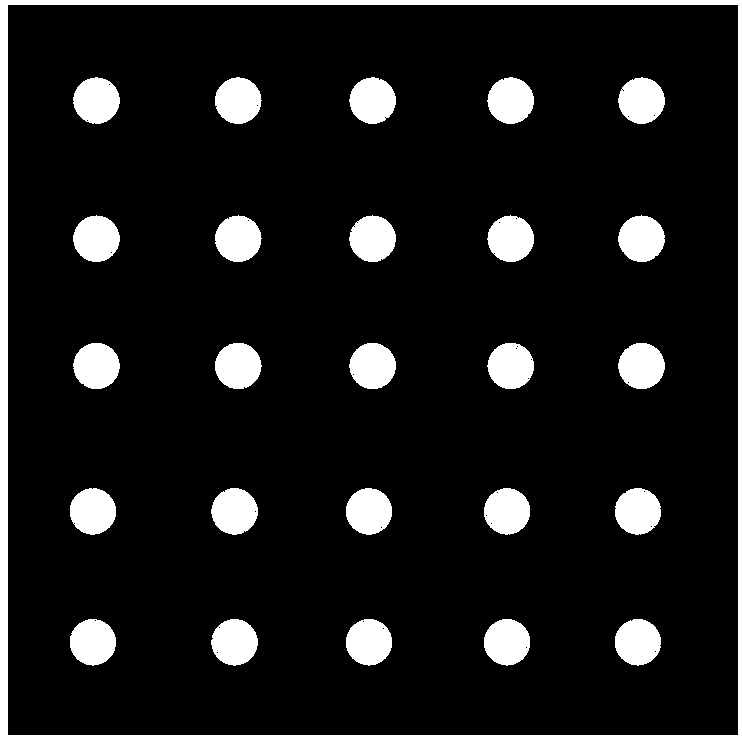

[0034] (1) Preparation of composite metal nanohole array substrate

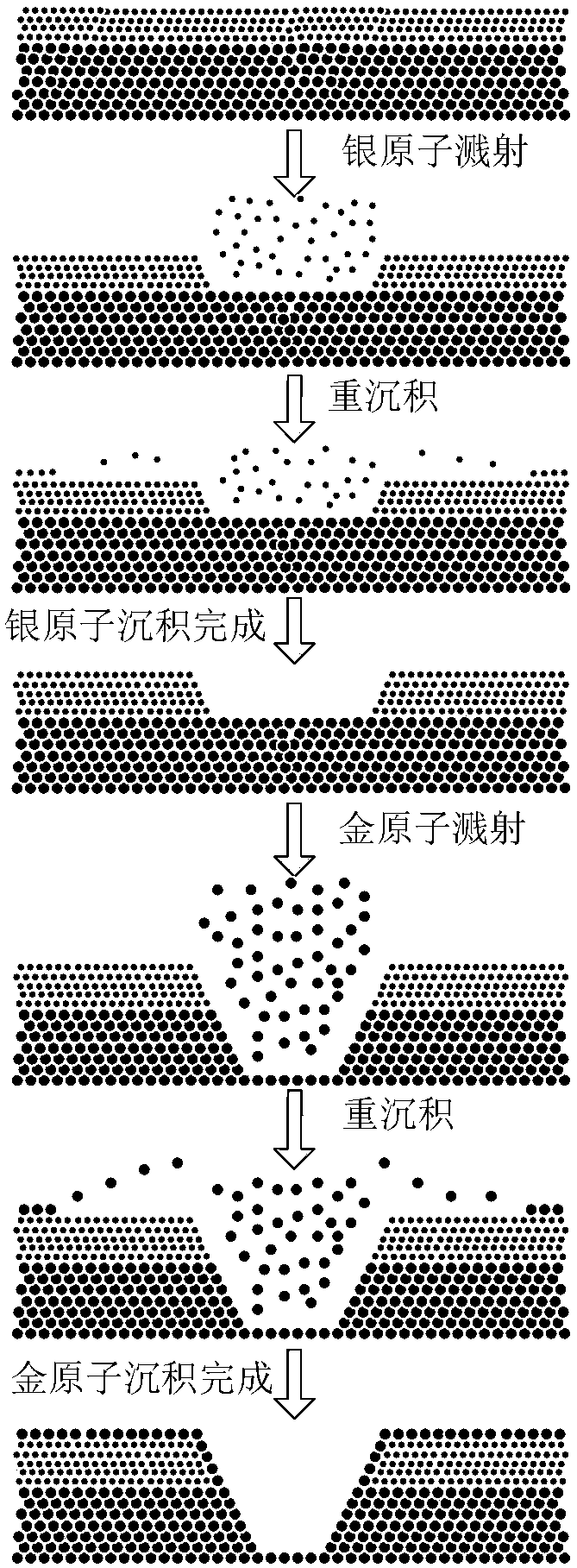

[0035] see figure 1 The flow chart of the preparation process of the composite metal nanohole array substrate. After the glass sheet 1 is cleaned by a plasma cleaning machine, a 2nm thick chromium layer 2 and a 100nm thick gold layer 3 are sequentially deposited from bottom to top using vacuum evaporation technology and a silver layer 4 with a thickness of 20nm, and then use the focused ion beam etching technique (etching principle see figure 2 ), using a gallium source, using a 15μm aperture, when the beam current is less than 5pA, the focused ion beam dose is 0.1nC / μm 2 Under the above conditions, the silver layer 4 is first etched, and the silver atoms sputtered during the etching process are re-deposited on the unetched place of the silver layer 4. After the silver layer 4 is etched through,...

Embodiment 2

[0039] Fabrication of Localized Electromagnetic Field Enhanced Devices for Raman Spectroscopy Characterization

[0040] (1) Preparation of composite metal nanohole array substrate

[0041] see figure 1 Process flow chart for the preparation of the composite metal nanohole array substrate. After cleaning the glass sheet 1 with a plasma cleaner, a 3nm-thick chromium layer 2 and a 50nm-thick gold layer 3 are sequentially deposited from bottom to top using vacuum evaporation technology. and a silver layer 4 with a thickness of 35nm, and then use the focused ion beam etching technique (etching principle see figure 2 ), using a gallium source, using a 15μm aperture, when the beam current is less than 5pA, the focused ion beam dose is 0.05nC / μm 2 Under the above conditions, the silver layer 4 is first etched, and the silver atoms sputtered during the etching process are re-deposited on the unetched place of the silver layer 4. After the silver layer 4 is etched through, the gold l...

Embodiment 3

[0045] Fabrication of Localized Electromagnetic Field Enhanced Devices for Raman Spectroscopy Characterization

[0046] (1) Preparation of composite metal nanohole array substrate

[0047] see figure 1 The flow chart of the preparation process of the composite metal nanohole array substrate. After the glass sheet 1 is cleaned by a plasma cleaning machine, a 2nm thick chromium layer 2 and a 75nm thick gold layer 3 are sequentially deposited from bottom to top using vacuum evaporation technology. and a silver layer 4 with a thickness of 50nm, and then use focused ion beam etching (etching principle see figure 2 ), using gallium source, 15μm aperture, when the beam current is less than 5pA, the focused ion beam dose is 0.02nC / μm 2 Under the above conditions, the silver layer 4 is first etched, and the silver atoms sputtered during the etching process are re-deposited on the unetched place of the silver layer 4. After the silver layer 4 is etched through, the gold layer 3 is et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com