Electrochromic device based on organic and inorganic composite material and preparing method of electrochromic device

A technology of electrochromic devices and inorganic composite materials, applied in instruments, nonlinear optics, optics, etc., can solve problems such as poor stability of electrochromic performance, unsatisfactory color changing effect, poor color changing performance, etc., and achieve obvious Effect of color change, low cost, and good electrochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

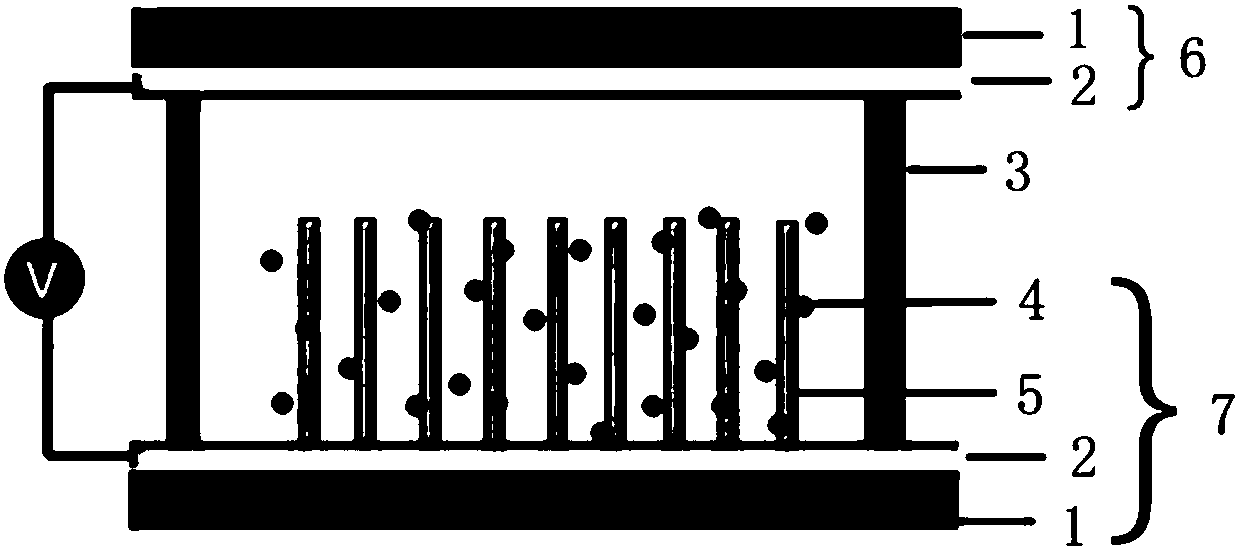

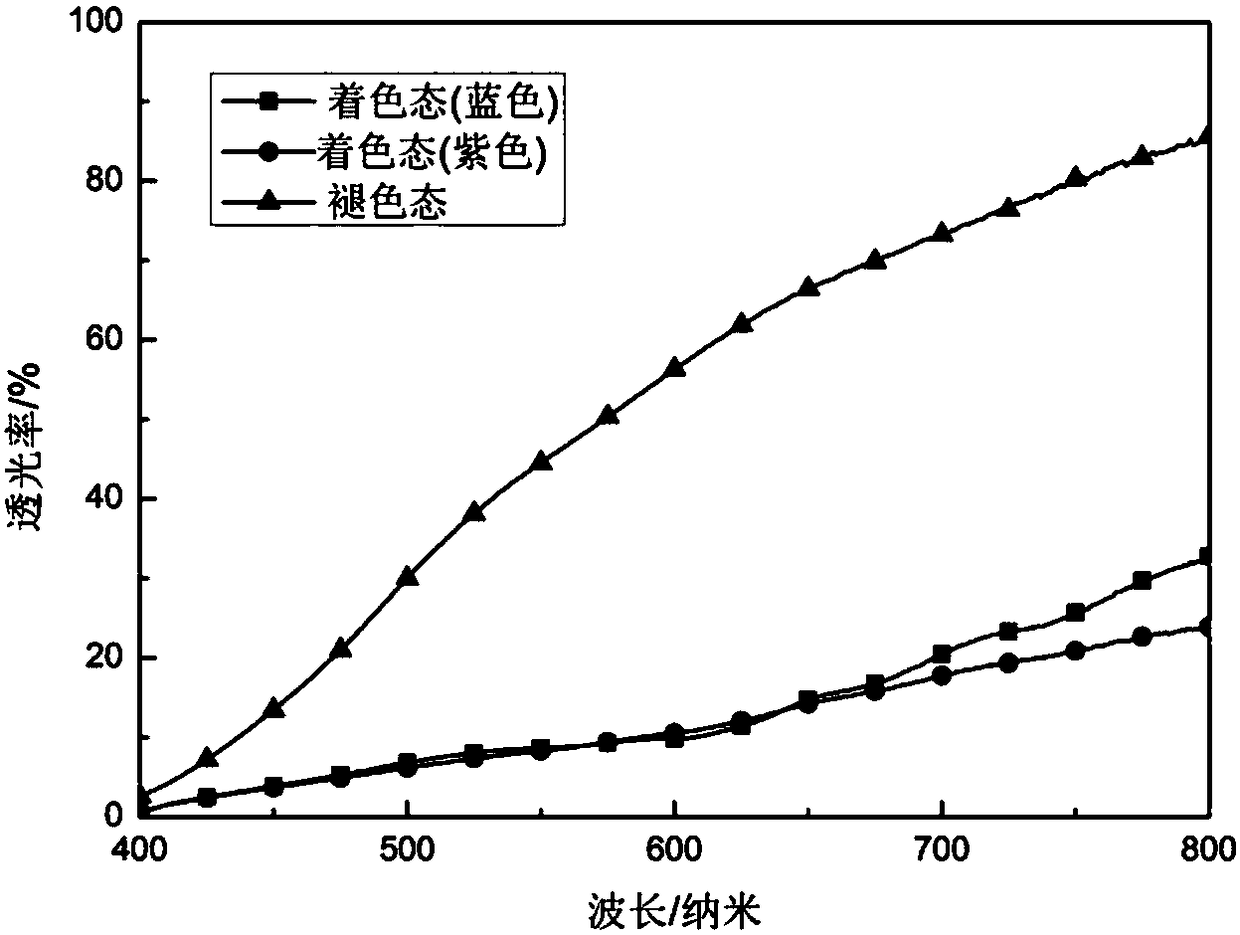

[0031] An electrochromic device based on organic-inorganic composite materials. The working electrode is TiO modified with methyl viologen solution grown on the surface. 2 Nanorod thin film FTO conductive glass, the counter electrode is FTO conductive glass, the electrolyte solution uses 0.2M LiClO 4 的γ-butyrolactone solution.

[0032] The structure diagram of the above electrochromic device is as figure 1 As shown, it can be seen from the figure that the upper FTO conductive glass is the counter electrode 6, and the lower surface is grown with TiO 2 The FTO conductive glass of nanorod 5 is the working electrode 7, and TiO 2 The nanorod 5 is modified with methyl viologen 4, the counter electrode and the working electrode are separated by a PET gasket 3, and there is an electrolyte between the two.

[0033] A method for preparing an electrochromic device based on an organic-inorganic composite material, the specific steps are as follows:

[0034] Step 1: Substrate cleaning. Place the ...

Embodiment 2

[0043] A method for preparing an electrochromic device based on an organic-inorganic composite material, the specific steps are as follows:

[0044] Step 1: Substrate cleaning. Place the FTO substrate (2×3cm 2 ) Were washed in acetone, absolute ethanol, and deionized water for 15 minutes, and then washed and dried naturally, and set aside.

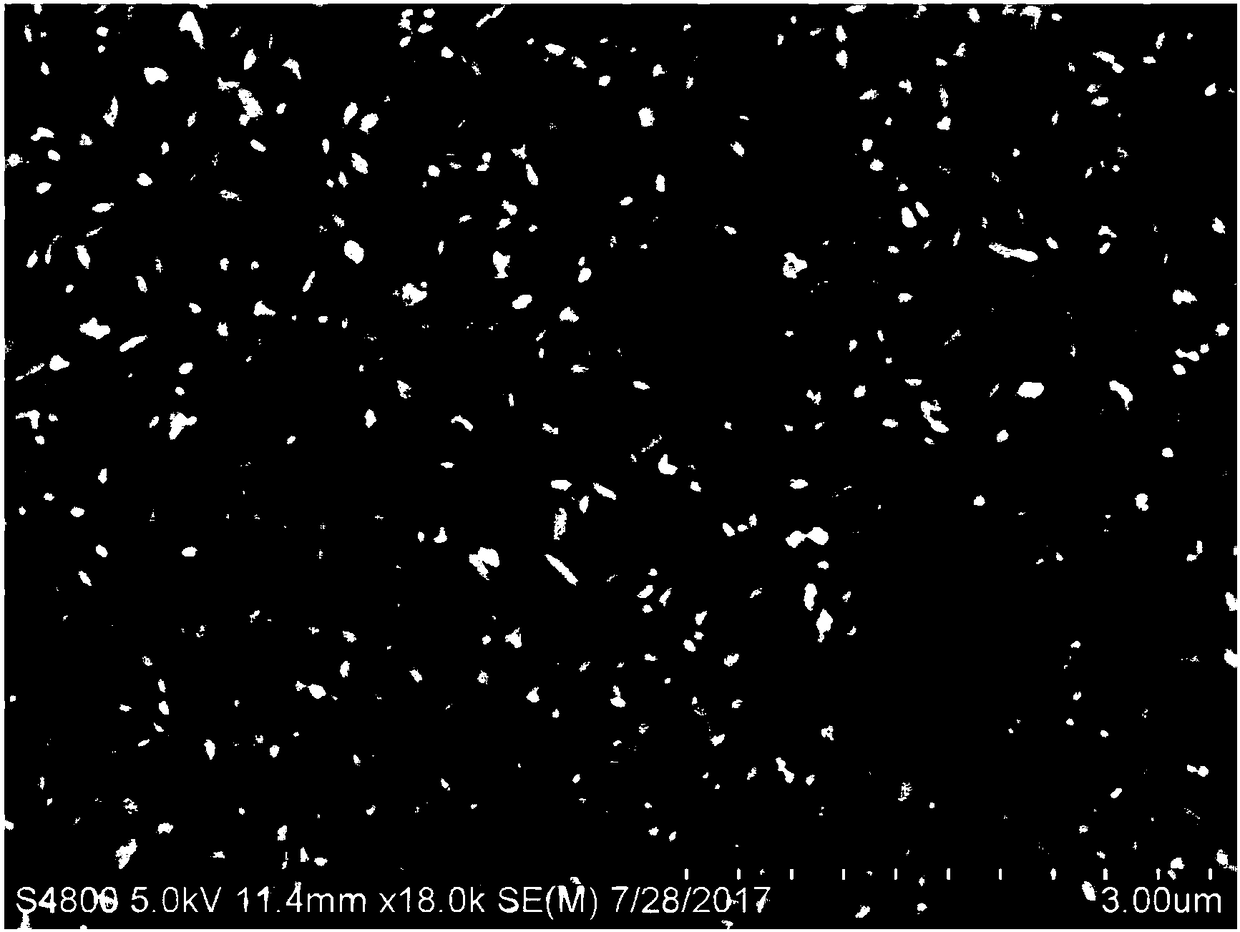

[0045] Step 2: Preparation of electrochromic layer. Slowly add 30 mL of deionized water to 30 mL of concentrated hydrochloric acid, add 1 mL of tetrabutyl titanate dropwise after magnetic stirring for 15 minutes, and continue magnetic stirring for 15 minutes. Then transfer the mixed solution to a hydrothermal kettle, put the FTO substrate in step 1 vertically, place the conductive surface downwards at a 45 degree angle to the substrate, seal it and put it in an oven at 180°C, grow it at high temperature for 3.5h Naturally cool to room temperature, take out the TiO 2 For the FTO substrate of the nanorod film, clean the surface of the film with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com