Reduced graphene oxide film photoelectric detector and preparation method and application thereof

A graphene film and photodetector technology, applied in the field of photoelectric detection, can solve the problems of complex processing method, low photoresponsivity, narrow detection light band, etc., and achieves simple preparation process, high photoelectric response rate, and low preparation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Preparation of reduced graphene oxide:

[0051] 1) Disperse graphene oxide in 5mL deionized water, ultrasonically disperse for 10-60min to obtain a graphene oxide solution (2mg / mL), then disperse it in a petri dish, and dry it at 40-80°C to remove water;

[0052] 2) Add 5 mL of 50% hydrazine hydrate solution to the dried culture dish, soak at 10-30° C. for 5-24 hours, and then wash with water and ethanol for 3-5 times respectively to obtain reduced graphene oxide.

Embodiment 2

[0054] The preparation method of reduced graphene oxide is the same as in Example 1.

[0055] Preparation of reduced graphene oxide thin film photodetectors with substrate:

[0056] 1) Add reduced graphene oxide to ethanol, ultrasonically disperse for 2-10 minutes, and make a dispersion with a concentration of 1.3 mg / mL;

[0057] 2) Apply 0.6mL of reduced graphene oxide dispersion evenly on the glass substrate by drop coating method, and then dry at 15-60°C for 5-24h to obtain reduced graphene oxide film, the size of the glass substrate is 13× 13mm, thickness 0.5-2.5mm;

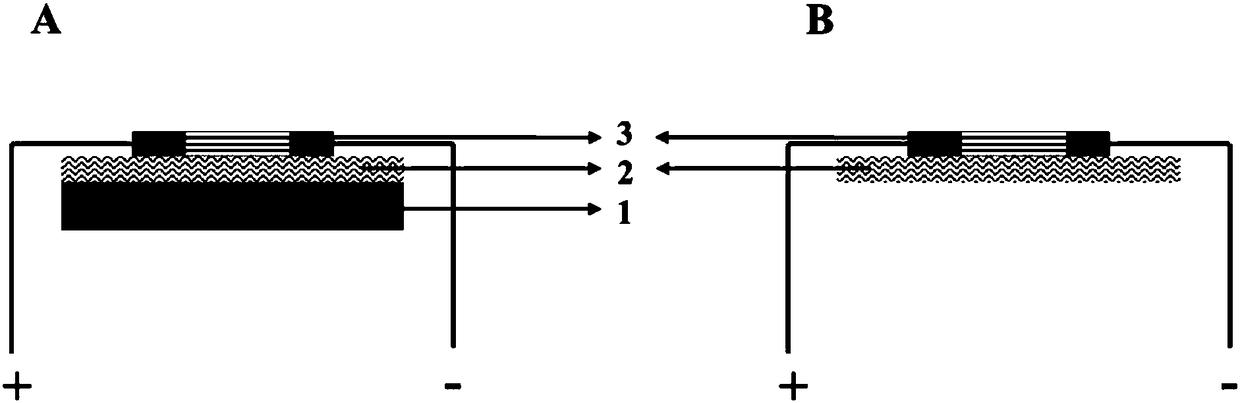

[0058] 3) Evaporating copper on the reduced graphene oxide film to obtain copper interdigitated electrodes, that is, to obtain the photodetector, the prepared reduced graphene oxide film photodetector structure schematic diagram is as follows figure 1 As shown in A, it can be seen from the figure that the photodetector includes a glass substrate 1 , a reduced graphene oxide film layer 2 , and copper interdi...

Embodiment 3

[0064] The preparation method of reduced graphene oxide is the same as in Example 1.

[0065] Preparation of reduced graphene oxide thin film photodetectors with substrate:

[0066] 1) Add reduced graphene oxide to ethanol, ultrasonically disperse for 2-10 minutes, and make a dispersion with a concentration of 1.3 mg / mL;

[0067] 2) Apply 0.9 mL of reduced graphene oxide dispersion evenly on a glass substrate by drop coating, and then dry at 15-60°C for 5-24 hours to obtain a reduced graphene oxide film with a glass substrate size of 13× 13mm, thickness 0.5-2.5mm;

[0068] 3) Evaporating copper on the reduced graphene oxide film to obtain copper interdigitated electrodes.

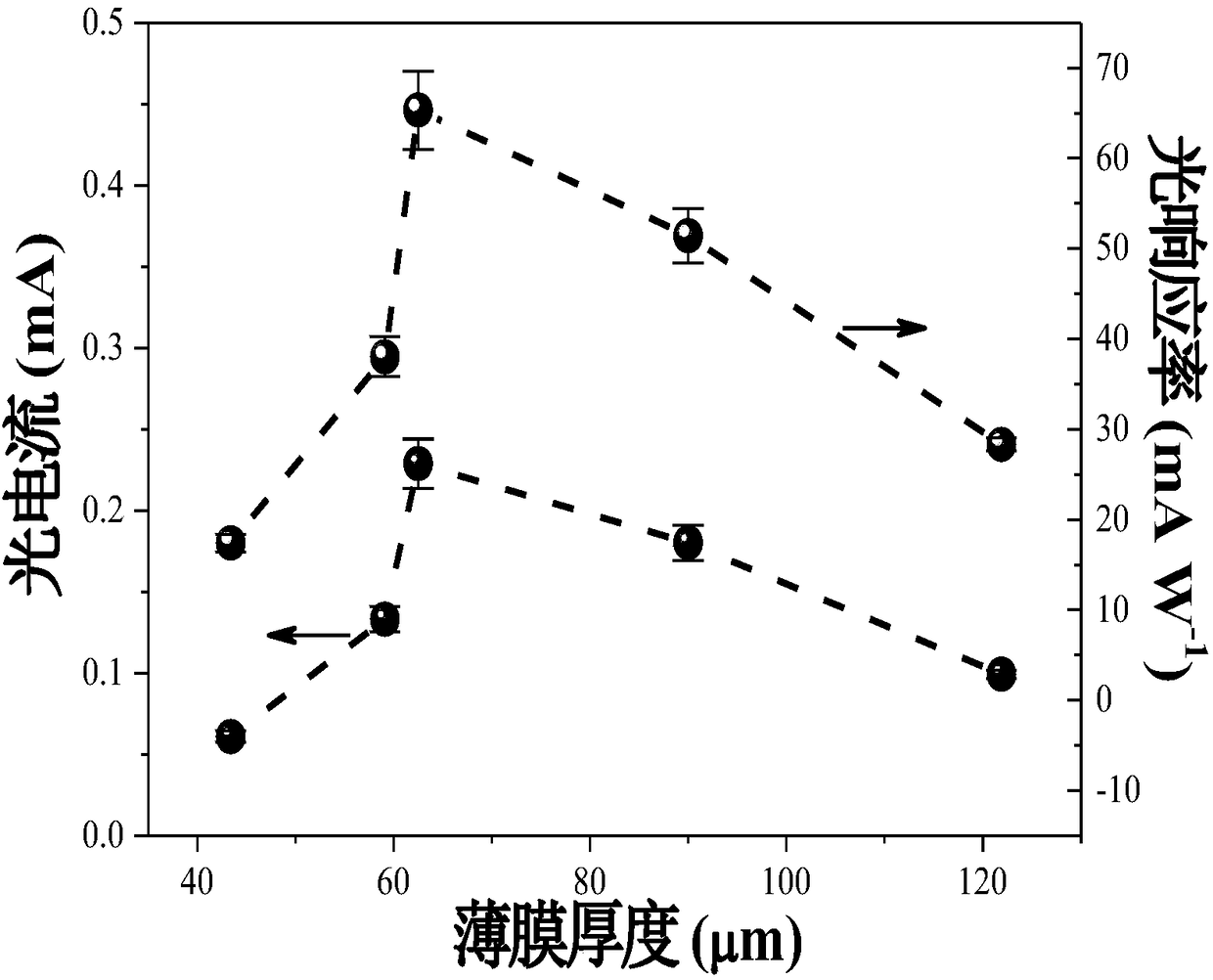

[0069] The resulting reduced graphene oxide film was analyzed by a scanning electron microscope, and the results showed that the thickness of the reduced graphene oxide film was 59.1 μm.

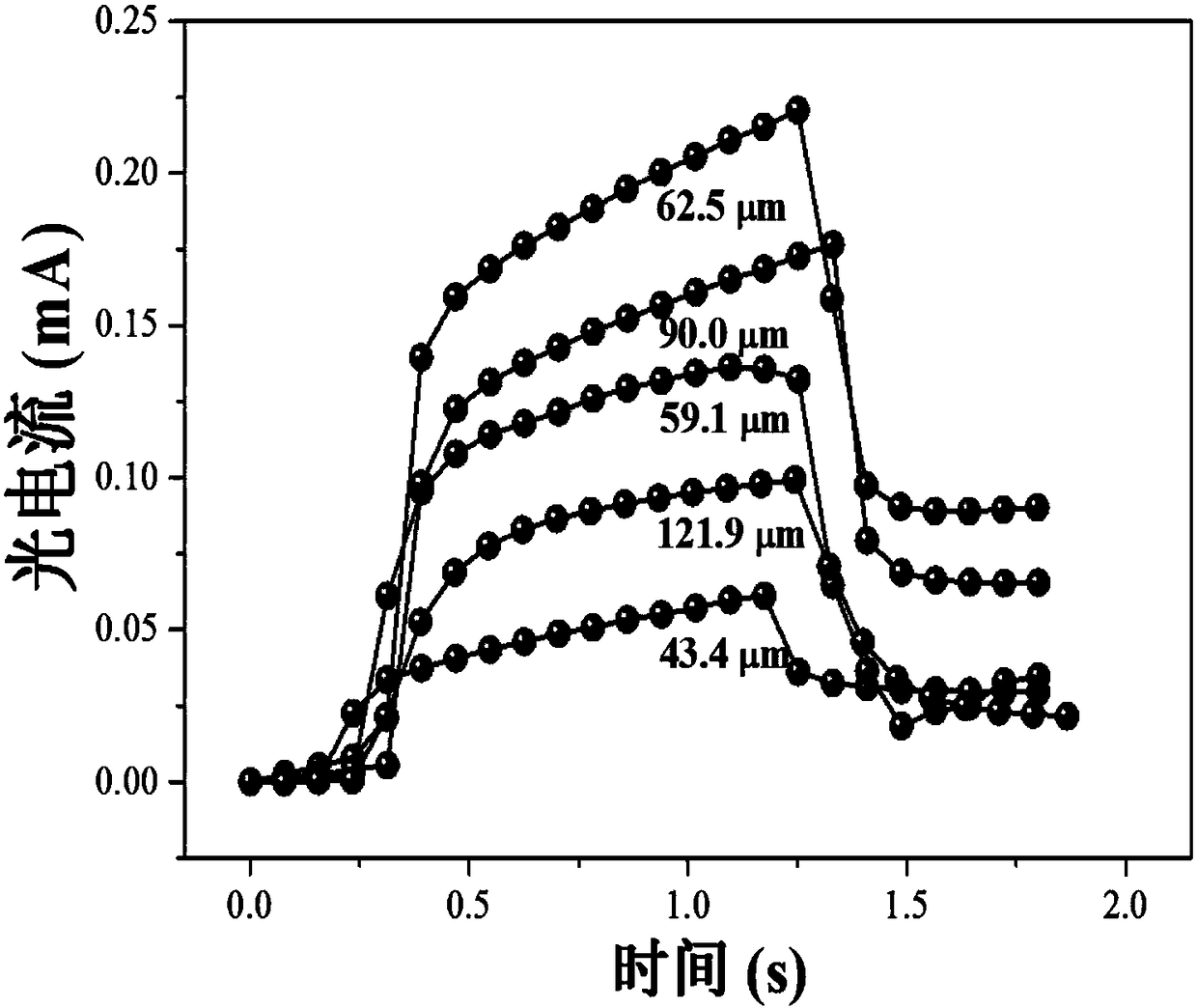

[0070] Photoelectric detection experiment:

[0071] A reduced graphene oxide film photodetector with a substrate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com