A method for preparing a magnetic tunnel junction array

A magnetic tunnel junction and array technology, which is applied in the manufacture/processing of magnetic field-controlled resistors and electromagnetic devices, can solve the serious loss of mask layer and magnetic tunnel junction material, reduce the magnetic and electrical performance of magnetic tunnel junction, Unfavorable problems such as magnetic memory yield, to improve magnetic/electrical performance and yield, increase anisotropic etching performance, and be conducive to miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

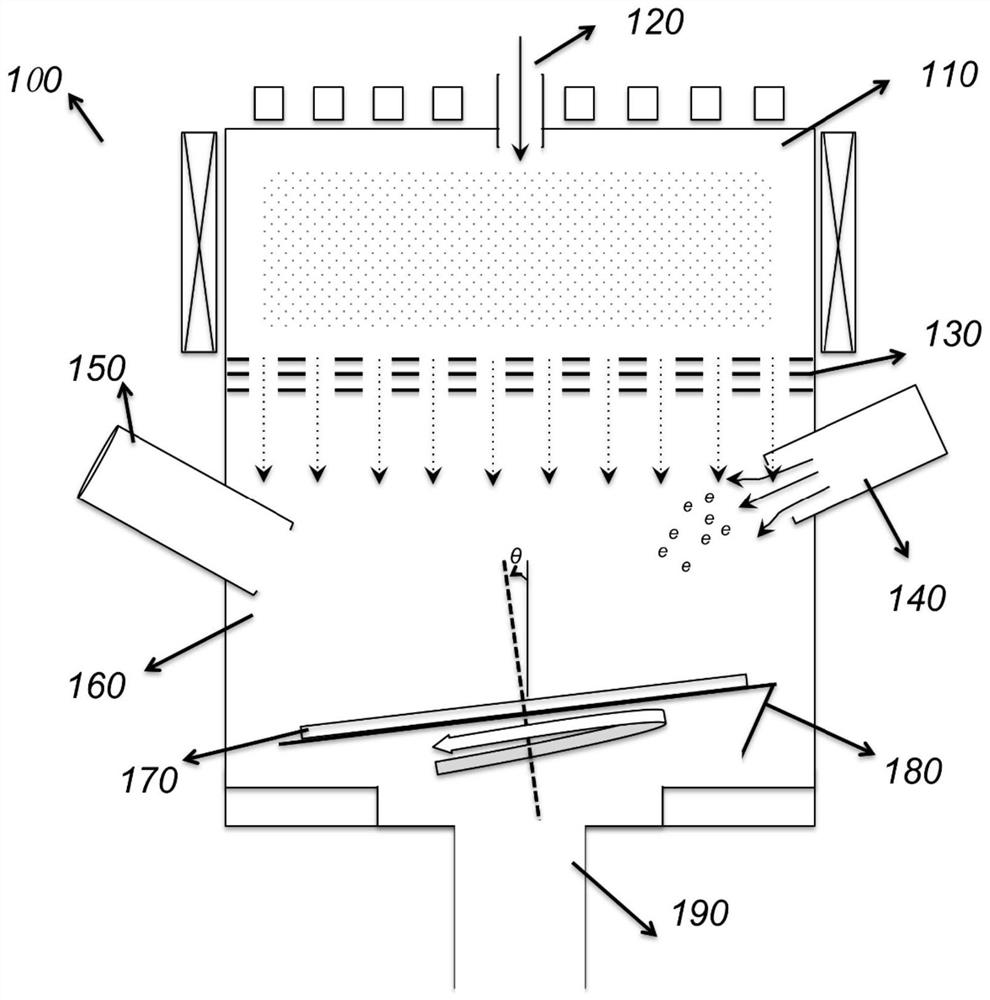

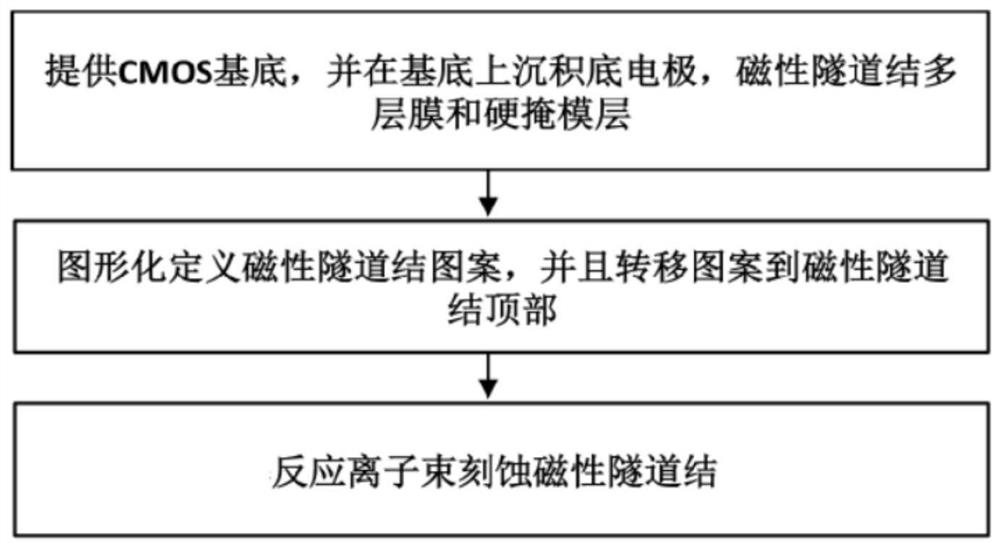

[0036] This embodiment provides a method for preparing a magnetic tunnel junction array by reactive ion beam etching, by using gases with carbonyl or hydroxyl functional groups, such as HCOOH, CH 3 OH, CH 3 COOH, C 2 h 5 OH, CO / NH 3 , as an ion source to etch the magnetic tunnel junction, and at the same time, perform small-angle ion beam trimming on the magnetic tunnel junction during and / or after etching. Its specific implementation steps are as follows figure 2 Shown:

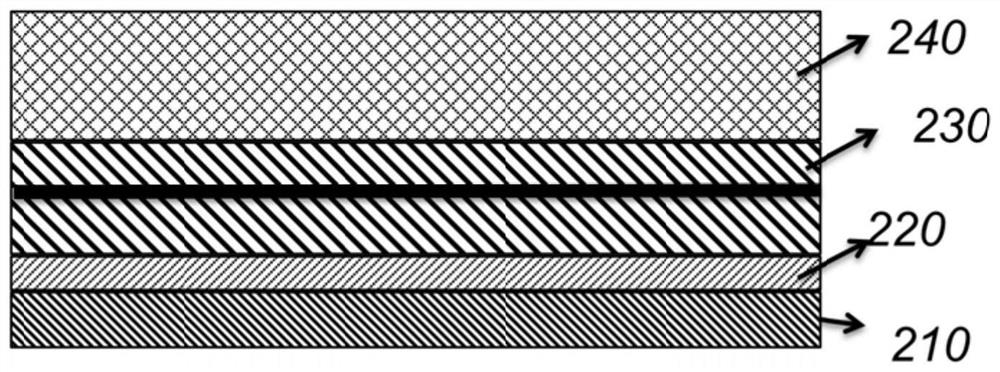

[0037] Step 1: Provide a CMOS substrate 210, and deposit a bottom electrode 220, a magnetic tunnel junction multilayer film 230 and a mask layer 230 on the substrate, such as image 3 shown;

[0038] Wherein, the bottom electrode 220 includes a seed layer and a conductive layer, the seed layer is Ta, TaN, W, WN, Ti or TiN, and the thickness of the seed layer is 0-5nm. In this embodiment, metal Ta is used to make a 3nm seed layer; The conductive layer is Cu, CuN, Mo, W or Ru, and the thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com