Synthetic method for drug intermediate acetonedicarboxylic acid

A technology of acetone dicarboxylic acid and a synthesis method, which is applied in the synthesis of acetone dicarboxylic acid pharmaceutical intermediates and the field of preparation of pharmaceutical intermediates, can solve problems such as health hazards for production operators, unfavorable safety production and the like, and achieves avoiding health hazards, Conducive to safe production and improved reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

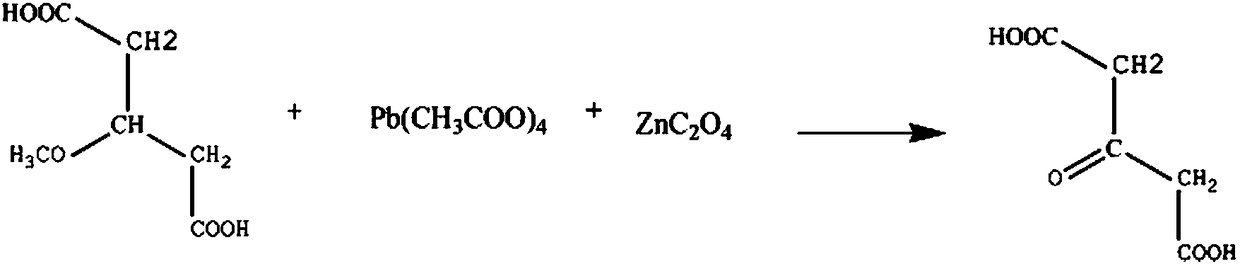

[0015] The synthetic method of acetone dicarboxylic acid medicine intermediate, comprises the steps:

[0016] A: Add 3mol 2-methoxypropane-1,3-dicarboxylic acid into the reaction vessel, 900ml mass fraction is 15% sodium nitrate solution, raise the temperature of the solution to 30°C, add 6mol in 2 times within 20min Lead tetraacetate, control stirring speed 150rpm, continue to react 80min;

[0017] B: Then add 6mol zinc oxalate powder, continue to react for 1h, lower the temperature to 15°C, add 10% potassium chloride solution for washing for 20 minutes, add 40% diphenyl ether solution for washing for 40 minutes, % recrystallized in diethylene glycol solution and dehydrated with anhydrous calcium sulfate dehydrating agent to obtain 427.926 g of finished acetone dicarboxylic acid with a yield of 97.7%.

Embodiment 2

[0019] The synthetic method of acetone dicarboxylic acid medicine intermediate, comprises the steps:

[0020] A: Add 3mol 2-methoxypropane-1,3-dicarboxylic acid into the reaction vessel, 900ml mass fraction is 18% sodium nitrate solution, raise the temperature of the solution to 33°C, add 7mol in 3 times within 30min Lead tetraacetate, control stirring speed 160rpm, continue to react 90min;

[0021] B: Then add 7mol zinc oxalate powder, continue the reaction for 1.5h, lower the temperature to 18°C, add a mass fraction of 13% potassium chloride solution for washing for 25 minutes, add a mass fraction of 44% diphenyl ether solution for washing for 50 minutes, Recrystallized in 63% diethylene glycol solution and dehydrated with anhydrous calcium sulfate dehydrating agent to obtain 428.802 g of acetone dicarboxylic acid with a yield of 97.9%.

Embodiment 3

[0023] The synthetic method of acetone dicarboxylic acid medicine intermediate, comprises the steps:

[0024] A: Add 3mol 2-methoxypropane-1,3-dicarboxylic acid into the reaction vessel, 900ml mass fraction is 22% sodium nitrate solution, raise the temperature of the solution to 36°C, add 8mol in 4 times within 40min Lead tetraacetate, control stirring speed 170rpm, continue to react 110min;

[0025] B: Then add 8 mol of zinc oxalate powder, continue to react for 2 hours, lower the temperature to 22°C, add a 16% potassium chloride solution for washing for 30 minutes, add a 47% diphenyl ether solution for washing for 60 minutes, and wash with a mass fraction of 65% % recrystallized in diethylene glycol solution and dehydrated with anhydrous calcium sulfate dehydrating agent to obtain 430.116 g of finished acetone dicarboxylic acid with a yield of 98.2%.

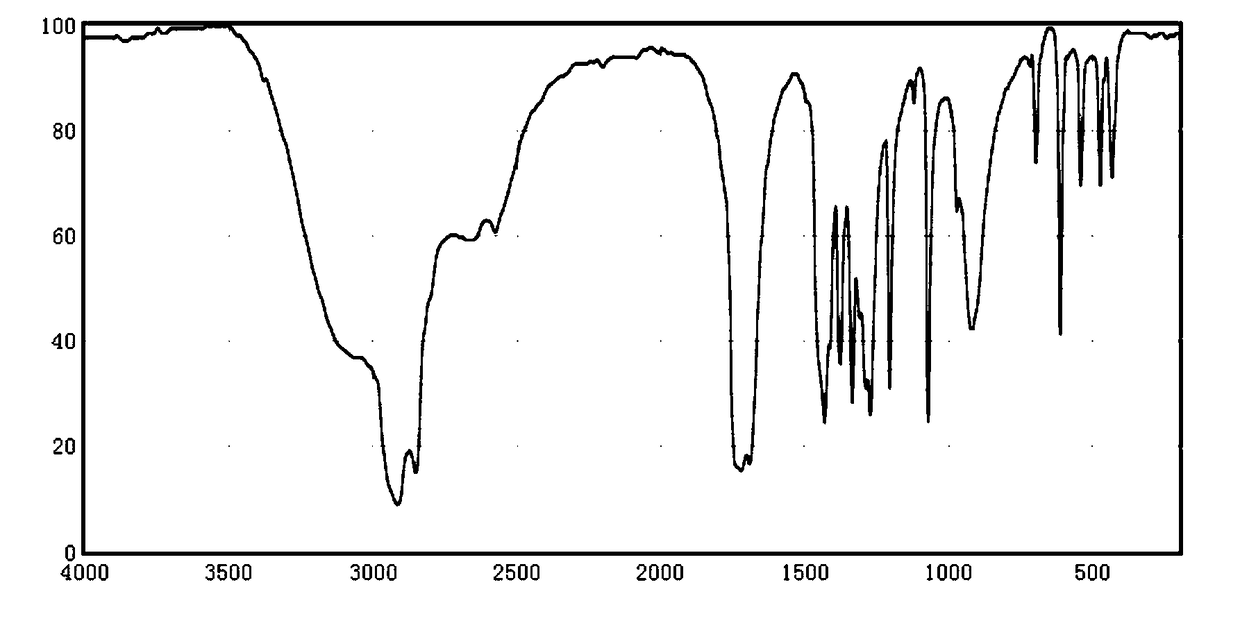

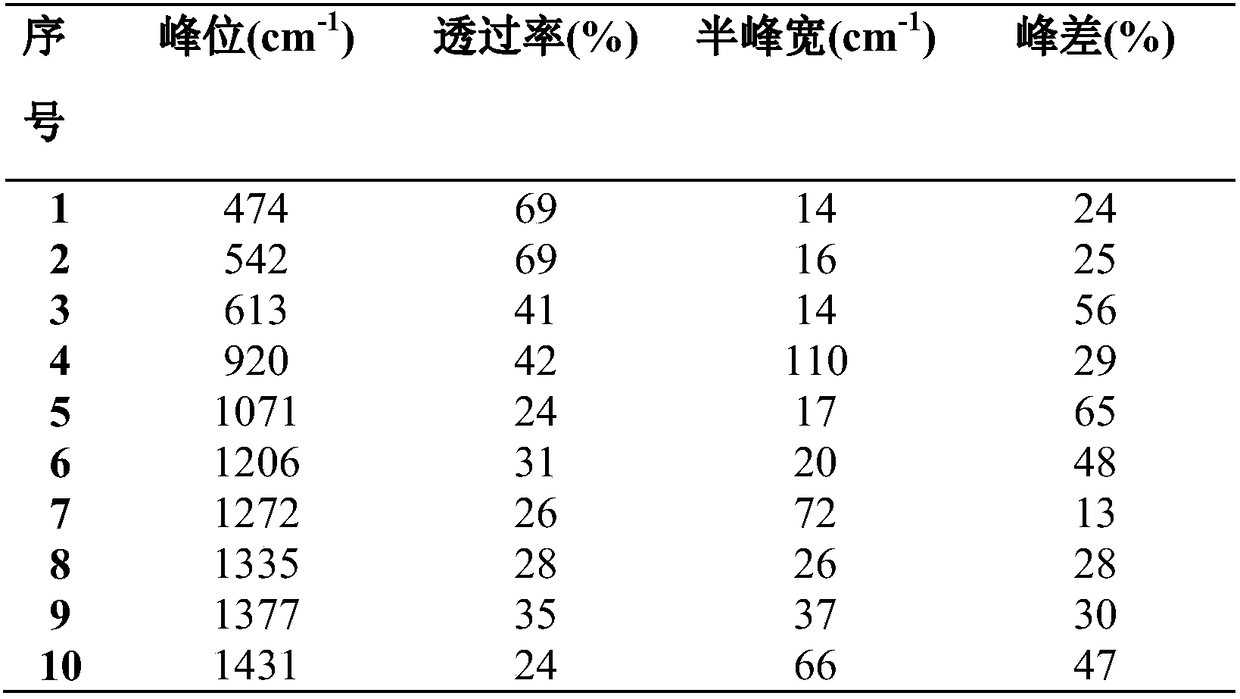

[0026] figure 1 It is the infrared analysis spectrogram of finished product acetone dicarboxylic acid.

[0027] Table 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com