Nifedipine drug intermediate o-nitrobenzaldehyde synthesis method

A technology of nitrobenzaldehyde and nifedipine, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of complicated process and low final yield, and achieve improved reaction yield and reaction time The effect of shortening and reducing the intermediate links of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

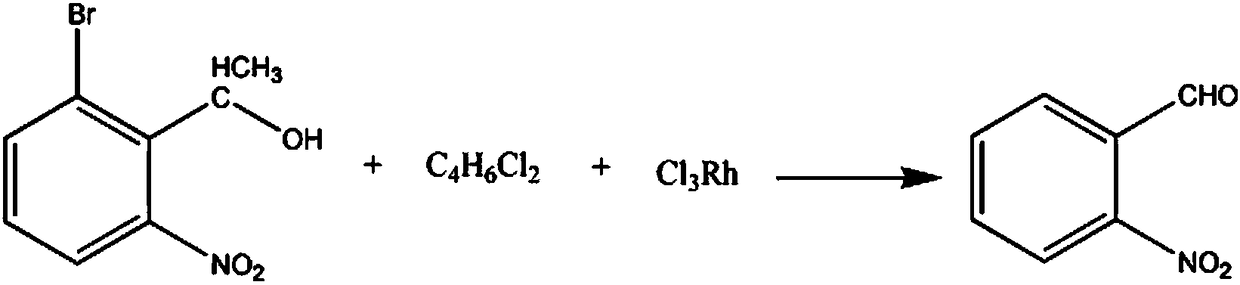

[0018] The synthetic method of nifedipine medicine intermediate o-nitrobenzaldehyde comprises the steps:

[0019] A, 2mol of 3-bromo-2-(1-hydroxyethyl)-nitrobenzene and 700ml mass fraction of 15% sodium nitrate solution are added to the reaction vessel, the stirring speed is controlled to 110rpm, and the temperature of the solution is lowered to 10°C. Reaction 60min, the mass fraction that adds 3mol is the dichlorobutene solution of 40%, adds 2mol rhodium trichloride in 3 times;

[0020] B. Continue to react for 40 minutes, separate layers, extract 3 times with 50% chlorodibromomethane solution, 5 times with 60% thionyl chloride solution, wash with 20% potassium nitrate solution Three times, the oil layer was separated, dehydrated with an activated alumina dehydrating agent, and recrystallized in a 3-chlorobenzotrifluoride solution with a mass fraction of 85%, to obtain 274.82 g of finished product o-nitrobenzaldehyde, with a yield of 91%.

Embodiment 2

[0022] The synthetic method of nifedipine medicine intermediate o-nitrobenzaldehyde comprises the steps:

[0023] A. Add 2mol of 3-bromo-2-(1-hydroxyethyl)-nitrobenzene and 750ml mass fraction of 18% sodium nitrate solution into the reaction vessel, control the stirring speed to 120rpm, reduce the solution temperature to 13°C, and react 70min, adding 3.5mol mass fraction is 43% dichlorobutene solution, adding 2.5mol rhodium trichloride in 4 times;

[0024] B. Continue to react for 50 minutes, separate the layers, extract 4 times with a 53% chlorodibromomethane solution, extract 6 times with a 64% thionyl chloride solution, and wash with a 23% potassium nitrate solution 5 times, the oil layer was separated, dehydrated with anhydrous calcium chloride dehydrating agent, and recrystallized in 3-chlorobenzotrifluoride solution with a mass fraction of 88%, to obtain 280.86 g of finished product o-nitrobenzaldehyde, with a yield of 93%.

Embodiment 3

[0026] The synthetic method of nifedipine medicine intermediate o-nitrobenzaldehyde comprises the steps:

[0027] A. Add 2mol of 3-bromo-2-(1-hydroxyethyl)-nitrobenzene and 800ml mass fraction of 22% sodium nitrate solution into the reaction vessel, control the stirring speed to 130rpm, reduce the solution temperature to 15°C, and react 80min, add 4mol mass fraction and be 47% dichlorobutene solution, add 3mol rhodium trichloride in 6 times;

[0028] B, continue to react for 60min, the solution is layered, and the mass fraction is 56% chlorodibromomethane solution extraction 5 times, the mass fraction is 68% thionyl chloride solution extraction 7 times, and the mass fraction is 27% potassium nitrate solution After washing 6 times, the oil layer was separated, dehydrated with activated alumina dehydrating agent, and recrystallized in 92% 3-chlorobenzotrifluoride solution to obtain 289.92 g of finished product o-nitrobenzaldehyde, with a yield of 96%.

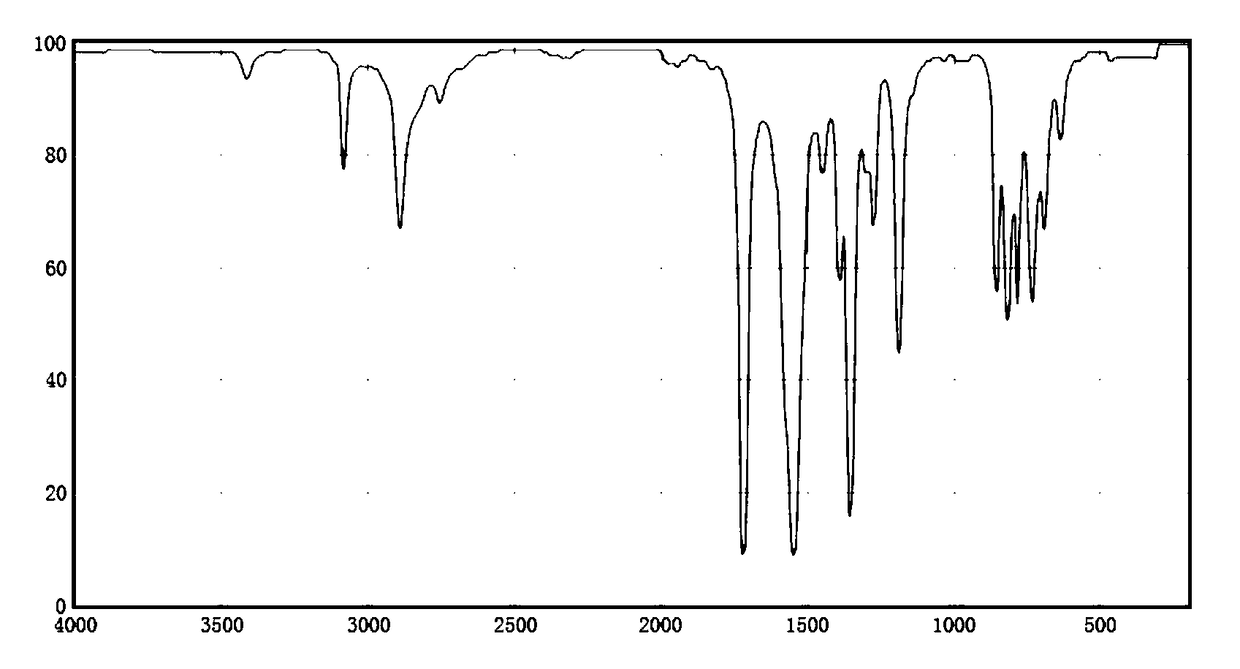

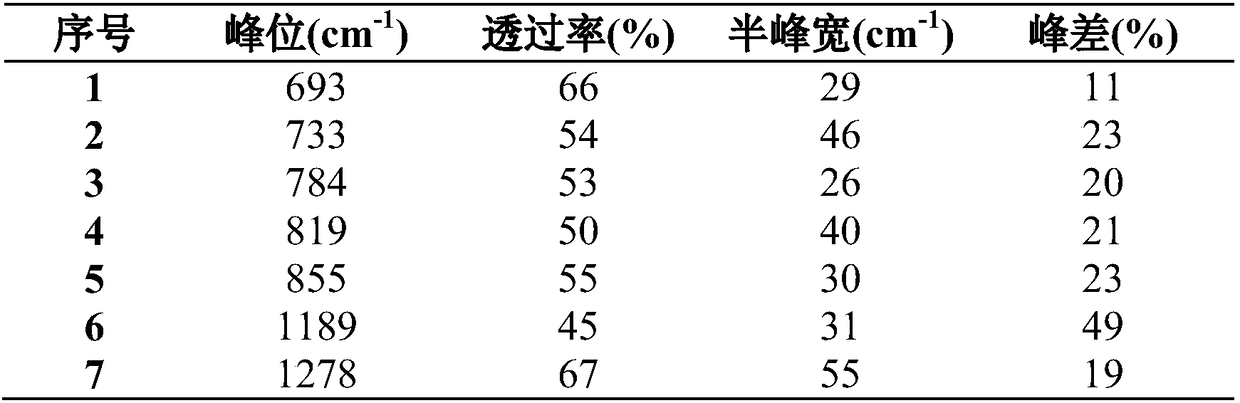

[0029] The finished prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com