Treatment method for wastes produced by fluidized-bed gasification

A fluidized bed gasification and treatment method technology, applied in the field of waste treatment, can solve the problems of poor combustion performance, short residence time, multi-energy and binder, etc., to meet the requirements of industrialization, realize utilization, method and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

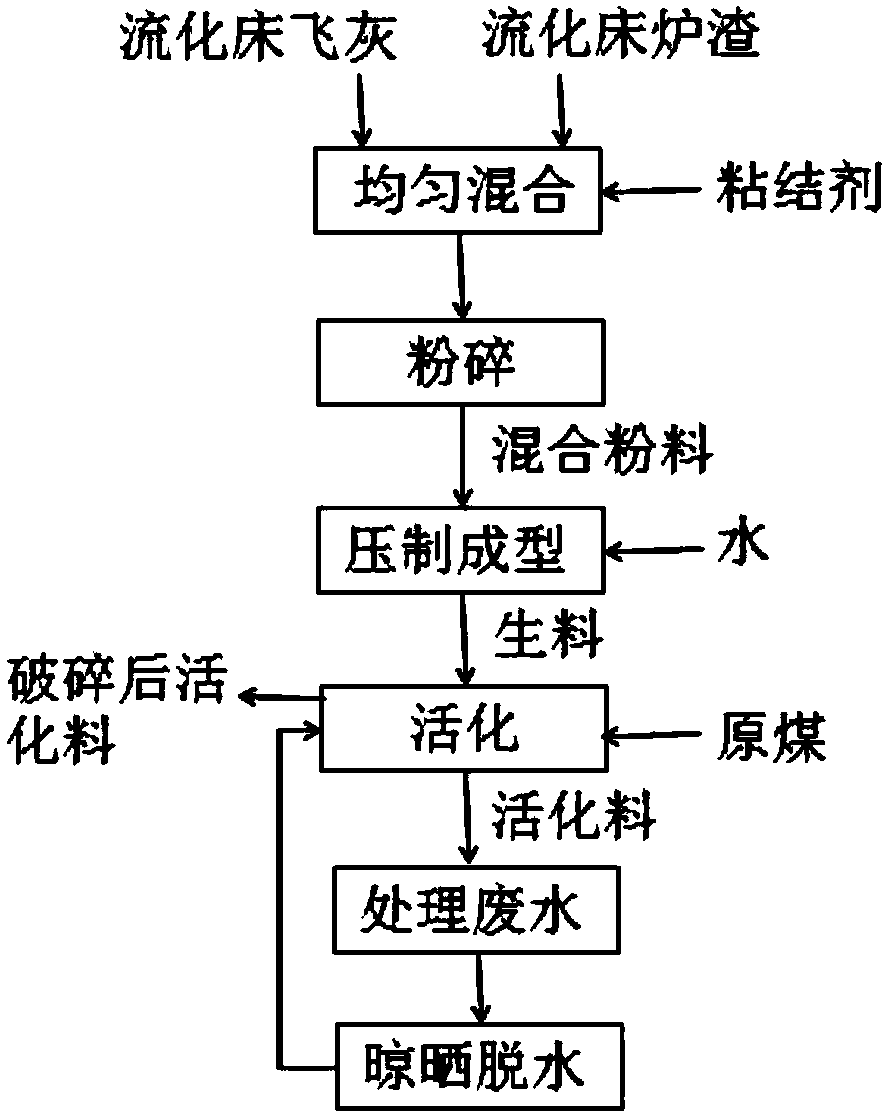

[0028] As a preferred embodiment of the present invention, step D is also included: using the activated material obtained in step C for adsorption treatment of wastewater, after the adsorption is completed, it is air-dried and dehydrated, and then sent to the gasifier for firing again to obtain the crushed Activation material, after being broken, the activation material and the activation material are discharged from the gasifier together, and after being screened and separated, the activation material is used again in the process of adsorption and treatment of wastewater. Furthermore, the carbon content of the crushed activated material obtained through sieving and separation reaches the standard and can be used as a building material.

[0029] In step D, after the activation material is fired again, the strength loss is large and it is broken, so that the activated material and the broken activation material can be screened and separated from the material discharged from the ...

Embodiment 1

[0040]The fluidized bed fly ash, fluidized bed slag, and binder are sent to a ball mill for crushing according to the weight ratio of 65:30:5, and a mixed powder with a particle size of ≤80 μm is obtained. Among them, the carbon content of the fluidized bed fly ash is 40 wt%, the particle size is 5-50 μm, and the carbon content of the fluidized bed slag is 10 wt%. Water is added to the mixed powder, mixed and pressed to obtain raw meal with a particle size of 5 mm. Send the raw material and raw coal into the gasifier according to the weight ratio of 0.3:1, and perform activation treatment at 950°C for 20 minutes to obtain the activated material. The activation material is used to adsorb and treat the waste water produced in the fluidized bed gasification process. After the adsorption is completed, the activation material is air-dried and dehydrated, and then sent to the gasification furnace for firing again to obtain a broken activation material. After the crushing, the activa...

Embodiment 2

[0042] The fluidized bed fly ash, fluidized bed slag, and binder are sent to a ball mill for crushing according to the weight ratio of 70:20:5, and a mixed powder with a particle size of ≤80 μm is obtained. Among them, the carbon content of the fluidized bed fly ash is 25 wt%, the particle size is 100-200 μm, and the carbon content of the fluidized bed slag is 5 wt%. Water is added to the mixed powder, mixed and pressed to form a raw meal with a particle size of 8 mm. Send the raw material and raw coal into the gasifier according to the weight ratio of 0.2:1, and perform activation treatment at 1050°C for 10 minutes to obtain the activated material. The application process of the activator is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com