A kind of denitrification catalyst and preparation method thereof

A denitration catalyst and solvent technology, applied in the field of flue gas denitration, can solve the problems of high qualification rate of catalyst catalyst, narrow applicable temperature range, low denitration removal rate, etc., achieve excellent catalytic activity, widen temperature adaptation width, and improve active load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

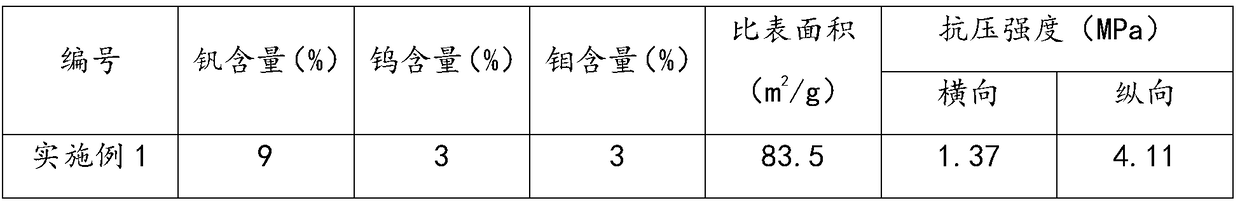

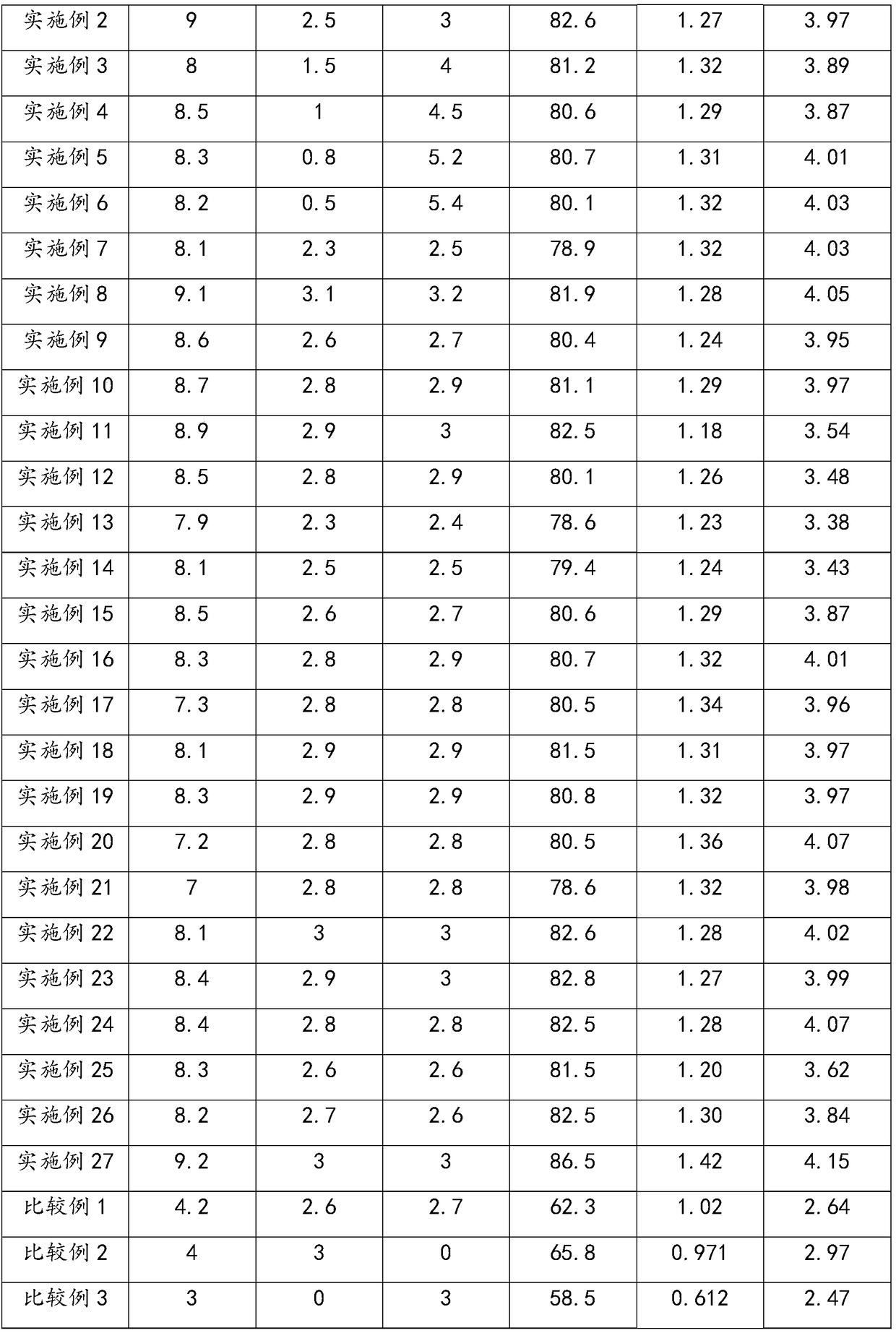

Examples

preparation example Construction

[0035] The present invention provides a kind of preparation method of denitration catalyst, comprises the following steps:

[0036] (a) dissolving the vanadium-containing compound in a solvent, and concentrating to obtain a concentrated solution of the vanadium-containing compound;

[0037] (b) uniformly mixing the carrier, the mixed solution of the tungsten-containing compound and the molybdenum-containing compound, and the concentrated solution of the vanadium-containing compound, kneading, molding, and calcining to obtain the denitration catalyst.

[0038] In a preferred embodiment of the present invention, the solvent in the step (a) includes monoethanolamine.

[0039] In a preferred embodiment of the present invention, the solvent in the step (a) is an aqueous solution of monoethanolamine. More preferably, the mass fraction of monoethanolamine in the aqueous solution of monoethanolamine is 15-25%, preferably 18-22%, more preferably 20%.

[0040] The monoethanolamine can...

Embodiment 1

[0059] The preparation method of the denitration catalyst described in this embodiment comprises the following steps:

[0060] (a) Mix 20g of monoethanolamine and 80g of deionized water to obtain an aqueous solution of monoethanolamine, add 23g of ammonium metavanadate to it, heat up to 95±3°C, stir for 40-90min until the solution is clear; then lower the temperature to 75- 80°C, maintained at this temperature, concentrated by stirring distillation, the concentration rate was 0.75, and the concentrated solution of vanadium-containing compounds was obtained.

[0061] (b) Get 60g titanium dioxide and 9g cordierite, mix with 5g mass fraction of 25% ammonia water and 10g deionized water, and pretreat the carrier (or mix ammonia water and deionized water to make a certain mass fraction of ammonia water Then mixed with the carrier, all can be);

[0062] Prepare a mixed solution of tungsten-containing compound and molybdenum-containing compound: Take 2.7g of ammonium metatungstate a...

Embodiment 2

[0065] The preparation method of the denitration catalyst described in this embodiment comprises the following steps:

[0066] (a) Mix 25g of monoethanolamine and 75g of deionized water to obtain an aqueous solution of monoethanolamine, add 46g of ammonium metavanadate to it, heat up to 93±3°C, stir for 40-90min until the solution is clear; then lower the temperature to 75- 80°C, maintained at this temperature, concentrated by stirring distillation with a concentration ratio of 0.9 to obtain a concentrated solution of vanadium-containing compounds.

[0067] (b) Get 60g titanium dioxide and 9g cordierite, mix with 5g mass fraction of 25% ammonia water and 10g deionized water, and pretreat the carrier (or mix ammonia water and deionized water to make a certain mass fraction of ammonia water Then mixed with the carrier, all can be);

[0068] Prepare a mixed solution of tungsten-containing compound and molybdenum-containing compound: Take 2.7g of ammonium metatungstate and 3.1g o...

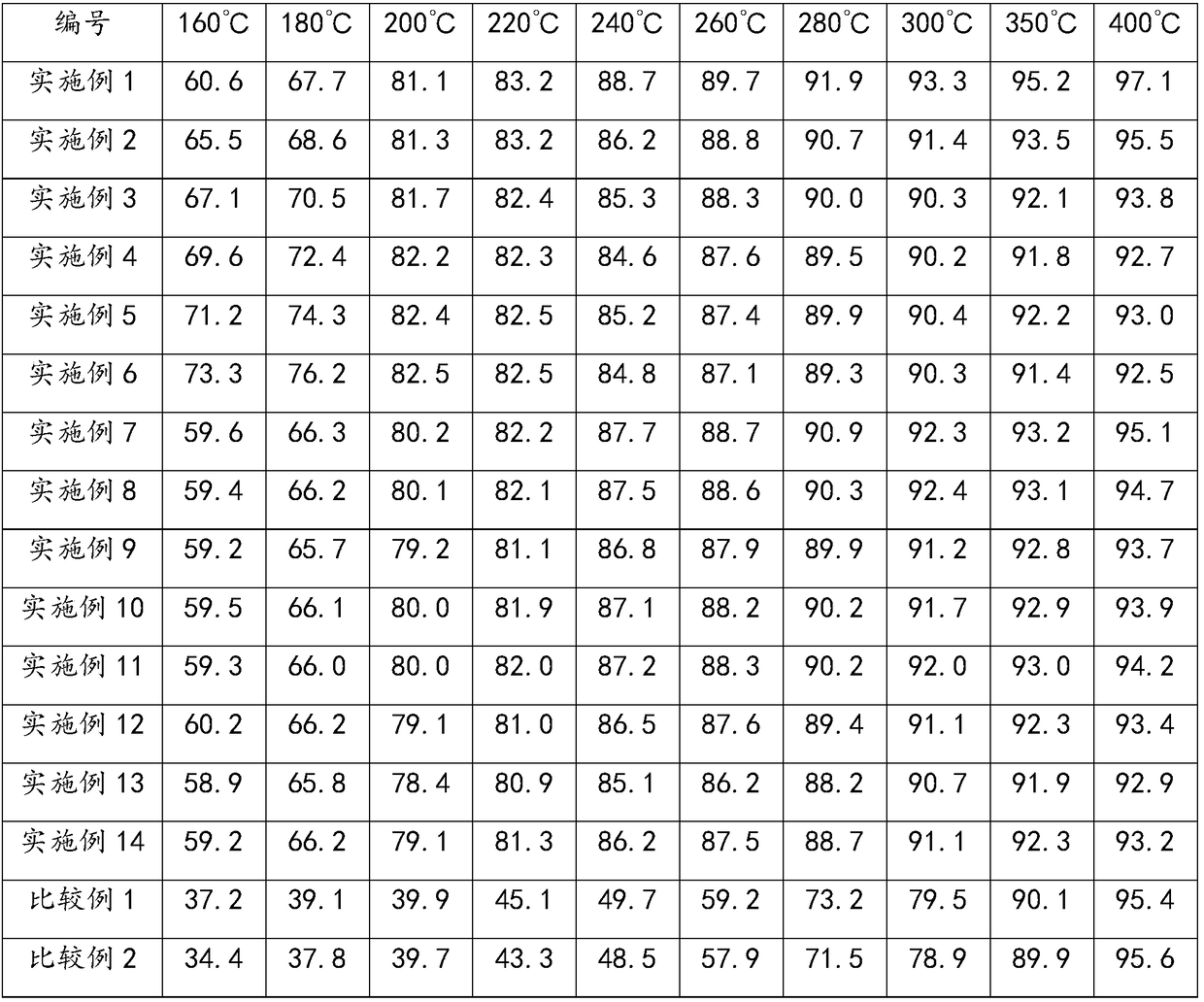

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com