A kind of denitrification catalyst and preparation method thereof

The technology of a denitration catalyst and a treatment method is applied in the field of catalyst resource utilization, and can solve the problems of reducing catalyst production cost, raw material loss, environmental pollution, cost increase, etc., and achieves reduction of production cost and raw material loss, production cost, production cost reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

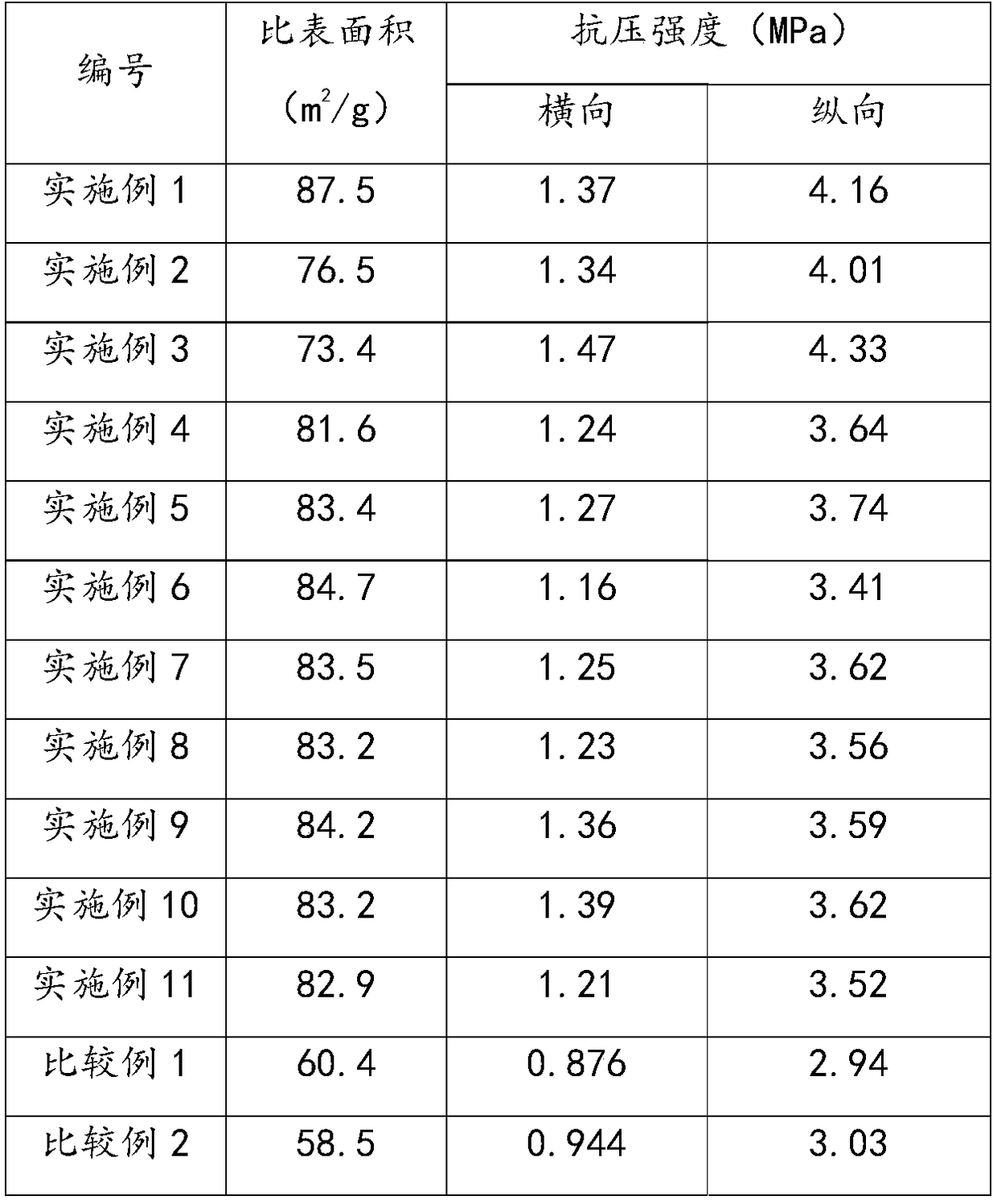

Examples

preparation example Construction

[0042] The present invention provides a kind of preparation method of denitration catalyst, comprises the following steps:

[0043] (a) mixing waste from the production process of the denitrification catalyst with the waste denitrification catalyst, making pulp, pressing, calcining and pulverizing to obtain clinker;

[0044] (b) After kneading the clinker, carrier, surface treatment agent, and active components, molding, drying, and calcining to obtain the catalyst.

[0045] In a preferred embodiment of the present invention, the waste from the production process of the denitration catalyst includes: waste sludge, waste water, fly ash and tail gas.

[0046] In a preferred embodiment of the present invention, the method for collecting and treating waste from the production process of the denitration catalyst includes:

[0047] The waste mud and waste water generated during the flushing production process are collected and precipitated through the pool to obtain the A material;...

Embodiment 1

[0063] The preparation method of the denitration catalyst described in this embodiment comprises the following steps:

[0064] (a) Preparation of clinker

[0065] Collection and disposal of waste from the production process of denitrification catalysts:

[0066] The waste mud and waste water generated during the process of flushing and producing the denitrification catalyst are collected and precipitated through the pool to obtain material A;

[0067] The fly ash is directly collected through the dust collector at the production site to obtain material B;

[0068] Through the ammonia washing tower and the tail gas absorption tower, the liquid and tail gas in the production process are processed and absorbed, and the generated wastewater is sent to the pool to collect the sediment to obtain the C material;

[0069] The material A, material B and material C obtained above are uniformly mixed to obtain the production process waste of the denitration catalyst.

[0070] Collecti...

Embodiment 2

[0077] This example refers to the preparation method of Example 1, and the only difference is that in the step (a), the obtained waste from the production process of the denitration catalyst and the waste denitration catalyst are mixed and pulped at a mass ratio of 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com