Process for dehydrogenating alkanes to olefins

A technology for alkane dehydrogenation and olefin production, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of no significant improvement in overall performance, high-temperature instability of chromium species, high cost of precious metals, etc. , to achieve the effect of simple operation, inhibition of coking, and improvement of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a preparation method of the catalyst, which is characterized in that the method comprises the following steps:

[0034] 1) Dry pretreatment of carbon material as template agent;

[0035] 2) Prepare a mixed aqueous solution of metal M salt and Zr salt;

[0036] 3) Add the mixed aqueous solution prepared in step 2) dropwise to the carbon material in step 1), and stir the resulting mixture to obtain a catalyst precursor;

[0037] 4) Drying and calcining the catalyst precursor in step 3) to obtain the catalyst MZr m O n .

[0038] In an embodiment of the present invention, the carbon material is selected from activated carbon or carbon black, such as granular activated carbon CGP, carbon black BP2000 or FW200; preferably carbon black, which has a specific surface area of 1100-1600 m 2 .g -1 , Preferably 1300-1500m 2 .g -1 The pore volume is 2-5mL / g, preferably 3-5mL / g. The carbon material can be prepared by a method known to those skilled in the...

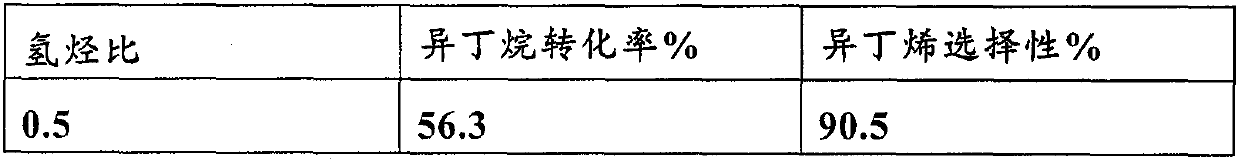

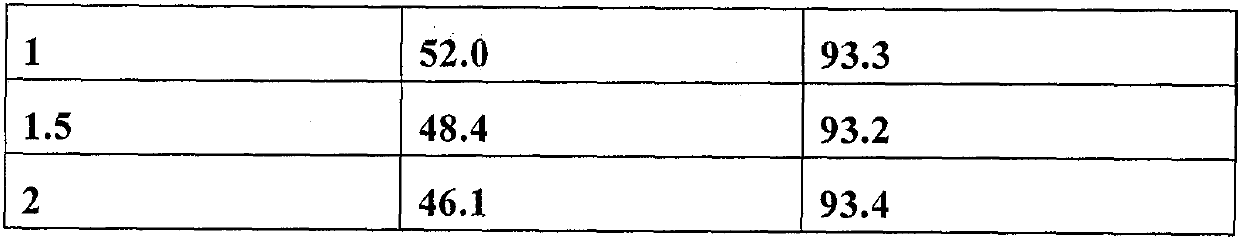

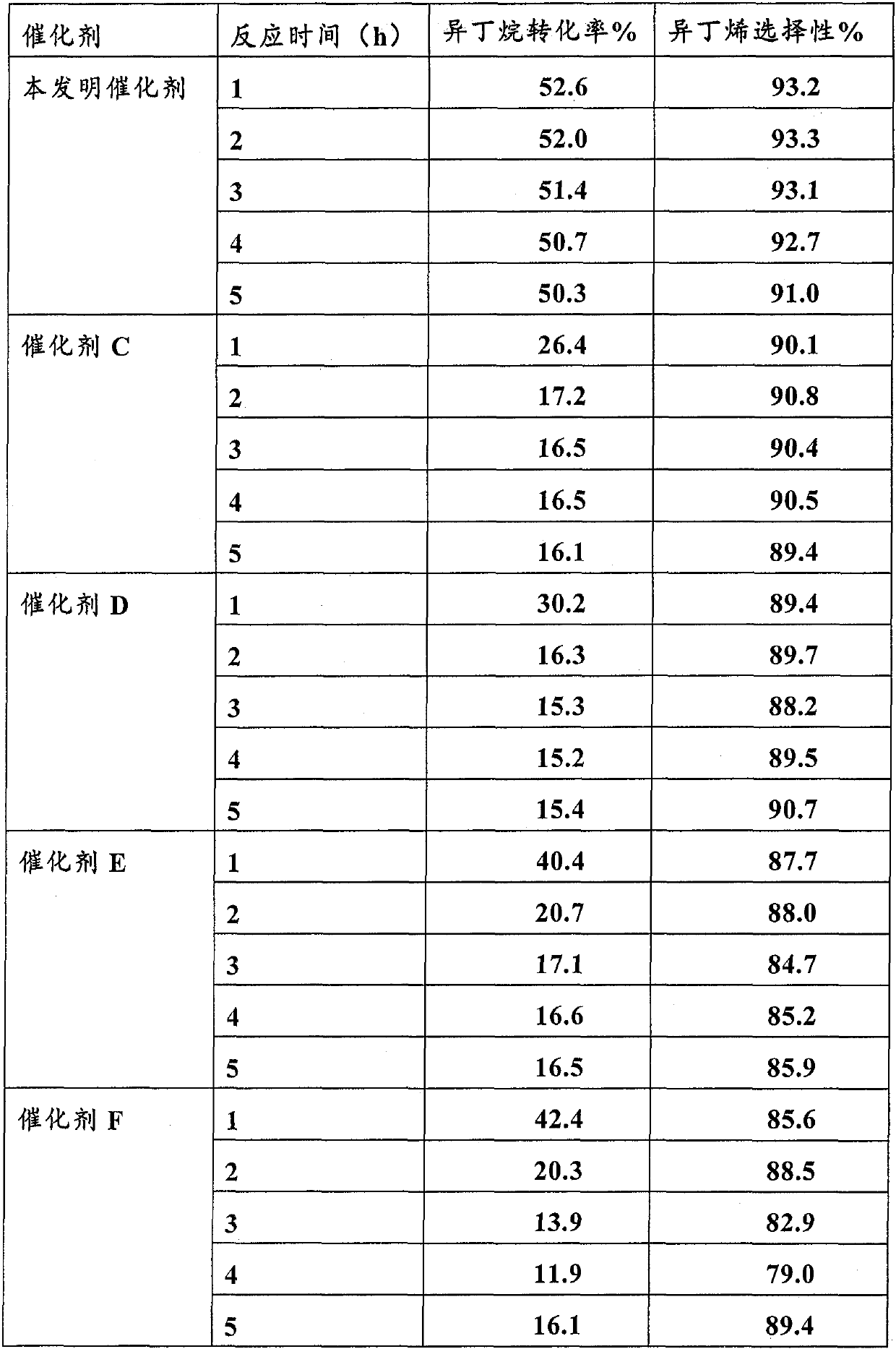

Embodiment 1

[0082] Put Cu(NO 3 ) 2 ·3H 2 O and ZrO (NO 3 ) 2 ·2H 2 O was prepared with deionized water to form a mixed aqueous solution of metal salt with a concentration of 0.15 mol / L, in which the molar ratio of Cu and Zr was 1:5. Then, it was sonicated at 40°C for 1 hour to obtain a clear solution. At room temperature 22°C, take 6g carbon material BP2000 and add 23.32g metal salt aqueous solution dropwise, stir for 1 hour, dry overnight at room temperature, dry at 80°C for 5 hours, and calcinate at 550°C for 20 hours. The obtained catalyst is denoted as CuZr 5 O n . The catalyst needs to be at 580℃, H 2 / N 2 Pre-reduction treatment under the atmosphere for 2 hours. See Table 1 for activity evaluation data.

Embodiment 2

[0084] Put Cu(NO 3 ) 2 ·3H 2 O and ZrO (NO 3 ) 2 ·2H 2 O is formulated with deionized water to form a mixed aqueous solution of metal salt with a concentration of 0.15 mol / L, in which the molar ratio of Cu and Zr is 1:10. Then, it was sonicated at 40°C for 1 hour to obtain a clear solution. At room temperature 22℃, take 6g carbon material BP2000 and add 23.44g metal salt aqueous solution dropwise, stir for 75 minutes, dry overnight at room temperature, dry at 80℃ for 5h, and calcinate at 550℃ for 20 hours. The obtained catalyst is denoted as CuZr 10 O n . The catalyst needs to be at 580℃, H 2 / N 2 Pre-reduction treatment under the atmosphere for 2 hours. See Table 1 for activity evaluation data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com