Method for manufacturing magnesium oxide and zinc oxide target billet

A manufacturing method and magnesium oxide technology, which is applied in the field of target sputtering, can solve the problems that the performance of the magnesium oxide zinc oxide target blank needs to be improved, and achieve the effects of improving density, microstructure uniformity, uniform color, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

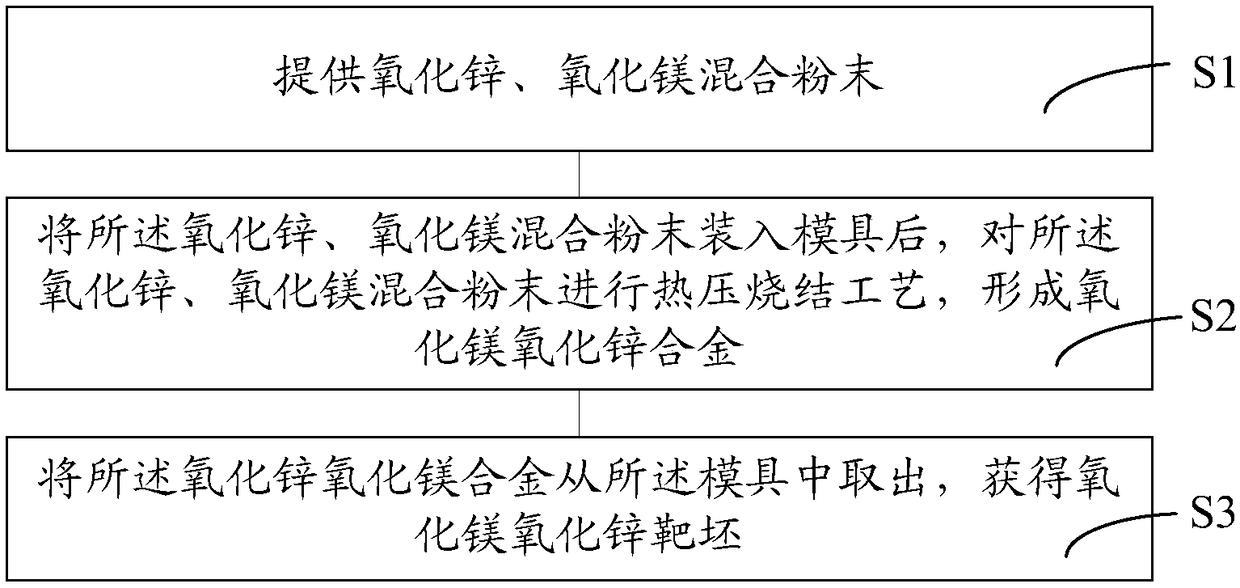

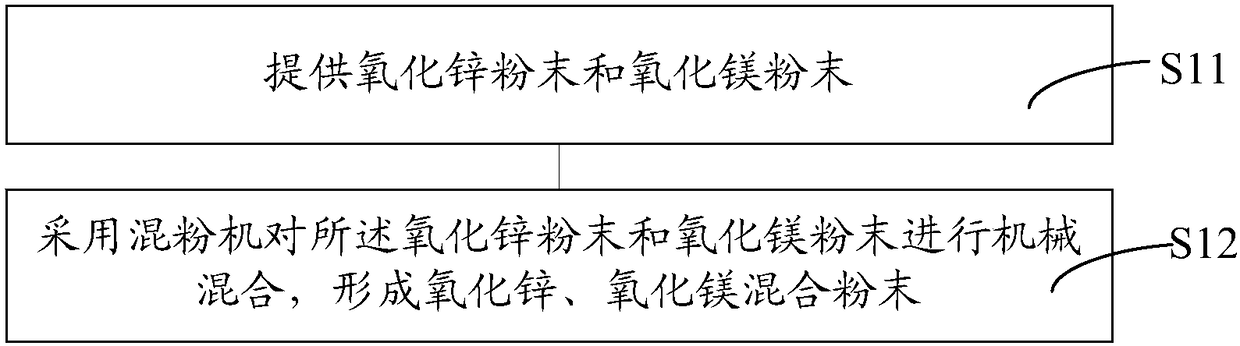

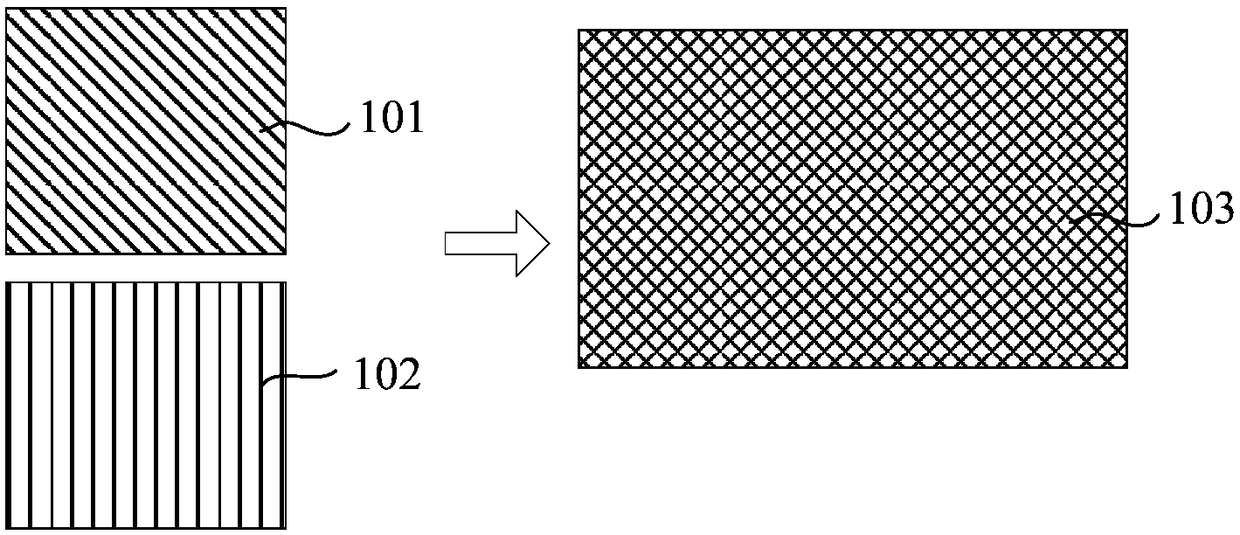

[0040] It can be seen from the background technology that the performance of the magnesium oxide zinc oxide target blank formed in the prior art needs to be improved. Analyze the reasons for this:

[0041]The manufacturing process of magnesium oxide zinc oxide target blank is mainly sintering at normal pressure or cold pressing after mixing. Therefore, the formed magnesium oxide zinc oxide target blank has low density, poor processability, microstructure uniformity and surface uniformity, and is prone to cracks, which makes it difficult for the formed magnesium oxide zinc oxide target blank to reach semiconductor, Solar energy, LCD and other industries use requirements. Therefore, there is an urgent need to provide a sintering process for the magnesium oxide zinc oxide target blank to ensure that the formed magnesium oxide zinc oxide target blank can meet the performance requirements of the sputtering target.

[0042] In order to solve the above problems, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com