Preparation method of ZnO micrometer/nanometer column LED

A nano-column, n-type technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost and complicated preparation process of ZnO nano-column, and achieve the effect of low cost, high effective utilization rate and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

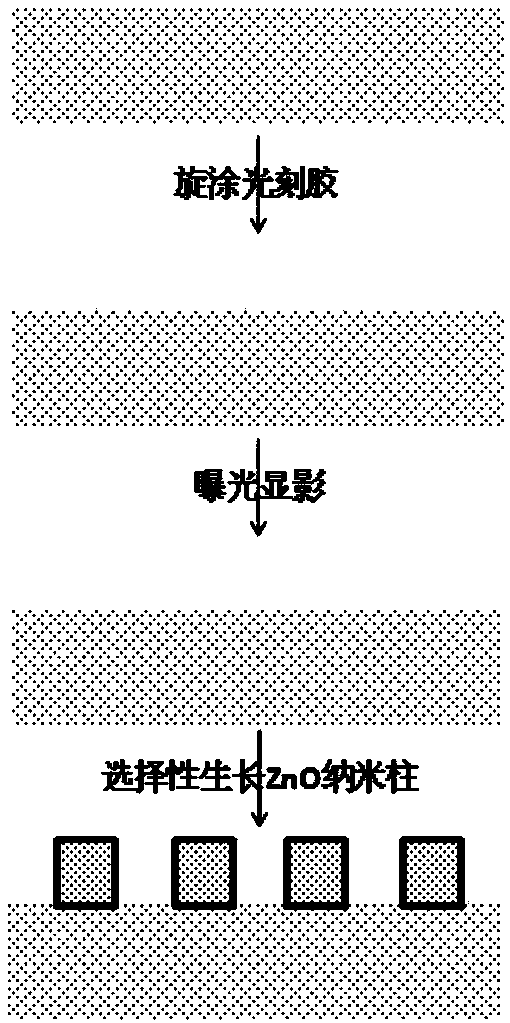

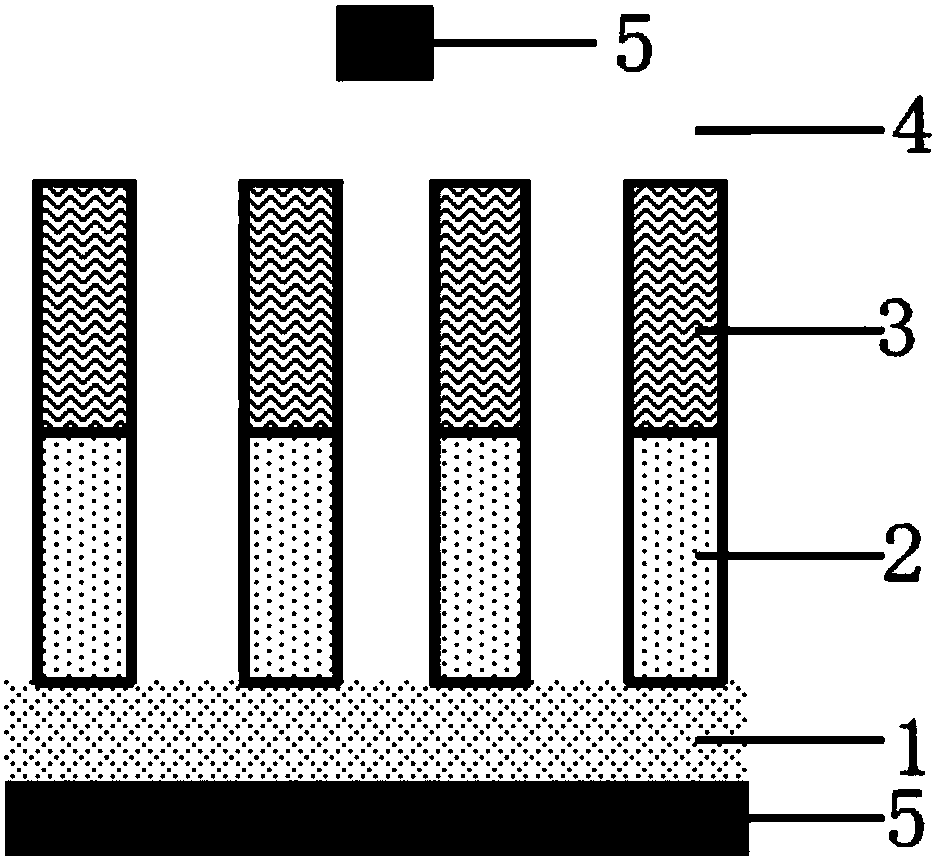

[0029] Such as figure 1 with figure 2 Shown, a kind of preparation method of ZnO micron / nanocolumn LED, comprises the following steps:

[0030] S1), spin coating photoresist on the p-type substrate 1, wherein, the substrate is a 2-inch single crystal LaAlO 3 ;

[0031] S2), using a pre-prepared mask plate for ultraviolet exposure and development treatment, to obtain the window for the growth of nano-columns, that is, to obtain a patterned substrate, the growth window is circular, and the diameter is 150nm, and the distance between the centers of the nano-columns is 0.5 microns ;

[0032] S3), put the patterned substrate into the ZnO solution doped with p-type dopant atoms Mg and Na atoms, grow p-type ZnO nanocolumns at 80°C for 28 hours, and use a magnetic stirrer to continuously stir during the growth process , to ensure the uniformity of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com