Recycling method of positive electrode material of waste lithium cobalt oxide battery

A cathode material and recycling method technology, which is applied in the field of harmless treatment and recycling of electrode materials, can solve the problems of low recovery efficiency of lithium cobalt oxide, poor environmental friendliness, and high energy consumption, and achieves easy operation, environmental friendliness, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

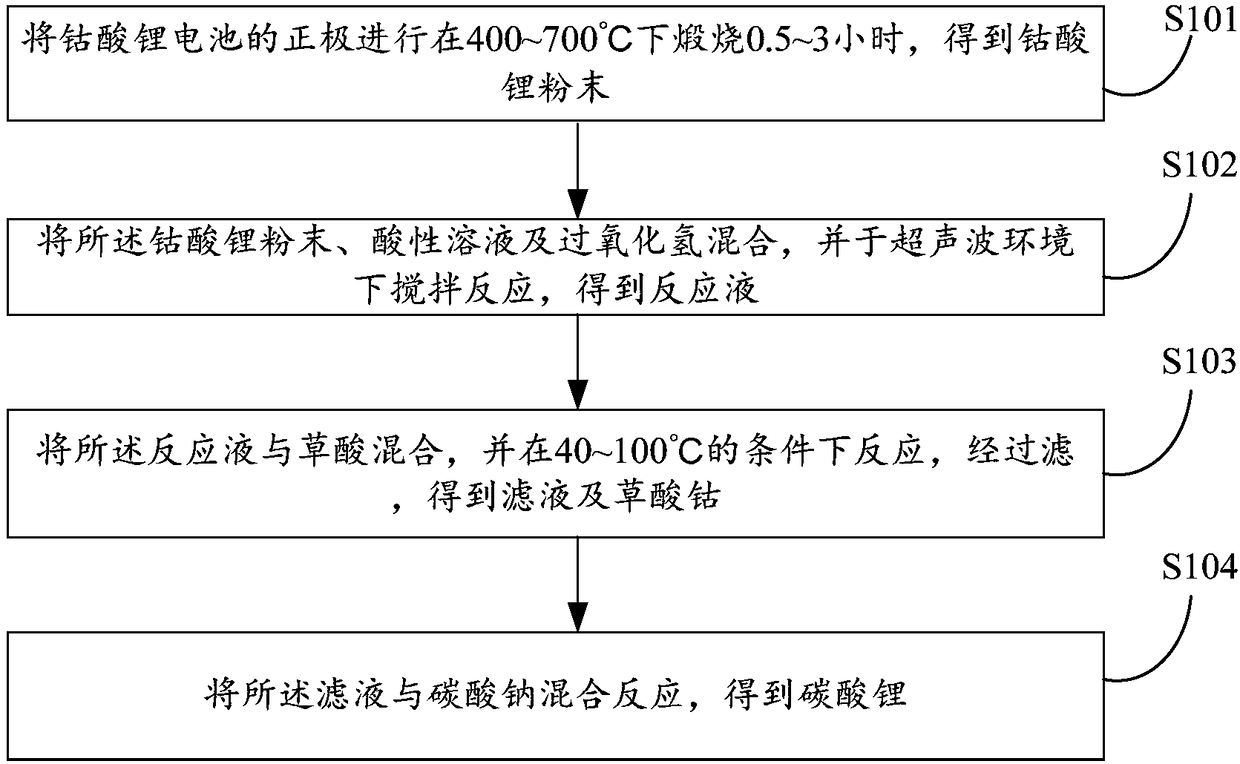

Method used

Image

Examples

Embodiment 1

[0049] (1) Firstly, the waste lithium cobalt oxide battery is discharged, and the positive plate of the battery can be obtained after disassembly. Put the positive electrode sheet into a muffle furnace for calcination, the calcination temperature is 400°C, and the calcination time is 3 hours, and finally black lithium cobaltate powder can be obtained;

[0050] (2) Lithium cobaltate powder is added in the there-necked flask that the mixed solution of sulfuric acid, citric acid and hydrogen peroxide is housed by the solid-liquid ratio of 10g / L, citric acid and H 2 SO 4 Concentration is 2.0M, H 2 o 2 The concentration is 2vol.%, and then the three-neck flask is placed in a magnetic stirrer with microwave and heating functions for reaction. The reaction temperature is 40°C, the microwave power is 400w, the reaction time is 3 hours, and the stirring speed in the magnetic stirrer is 50r / min,;

[0051] (3) Adding concentration to the solution is 1.0M oxalic acid to react, the re...

Embodiment 2

[0055] (1) Firstly, the waste lithium cobalt oxide battery is discharged, and the positive plate of the battery can be obtained after disassembly. Put the positive electrode sheet into a muffle furnace for calcination, the calcination temperature is 550°C, and the calcination time is 2 hours, and finally black lithium cobaltate powder can be obtained;

[0056] (2) Add lithium cobaltate powder into a three-necked flask equipped with a mixture of sulfuric acid, hydrochloric acid and hydrogen peroxide at a solid-to-liquid ratio of 60g / L, the concentration of hydrochloric acid and sulfuric acid is 3.0M, and the concentration of H 2 o 2 The concentration is 3vol.%, and then the three-neck flask is placed in a magnetic stirrer with microwave and heating functions for reaction. The reaction temperature is 60°C, the microwave power is 700w, the reaction time is 3 hours, and the stirring speed in the magnetic stirrer is 200r / min,;

[0057] (3) Adding a concentration of 2M oxalic aci...

Embodiment 3

[0061] (1) Firstly, the waste lithium cobalt oxide battery is discharged, and the positive plate of the battery can be obtained after disassembly. Put the positive electrode sheet into a muffle furnace for calcination, the calcination temperature is 700°C, the calcination time is 0.5 hours, and finally black lithium cobaltate powder can be obtained;

[0062] (2) Add lithium cobaltate powder into a three-necked flask equipped with a mixture of sulfuric acid, hydrochloric acid and hydrogen peroxide at a solid-to-liquid ratio of 100g / L, the concentration of hydrochloric acid and sulfuric acid is 5.0M, and the concentration of H 2 o 2 The concentration is 5vol.%, and then the three-neck flask is placed in a magnetic stirrer with microwave and heating functions for reaction. The reaction temperature is 100°C, the microwave power is 1000w, the reaction time is 3 hours, and the stirring speed in the magnetic stirrer is 300r / min,;

[0063] (3) Adding concentration to the solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com