A kind of preparation method of nano magnetic beads modified by gold nanoparticles

A gold nanoparticle and nanomagnetic bead technology, which is used in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the harsh synthesis process, uneven coating on the surface of magnetic microspheres, and stable complexes Poor performance and other problems, to achieve the effect of uniform modification, improved stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

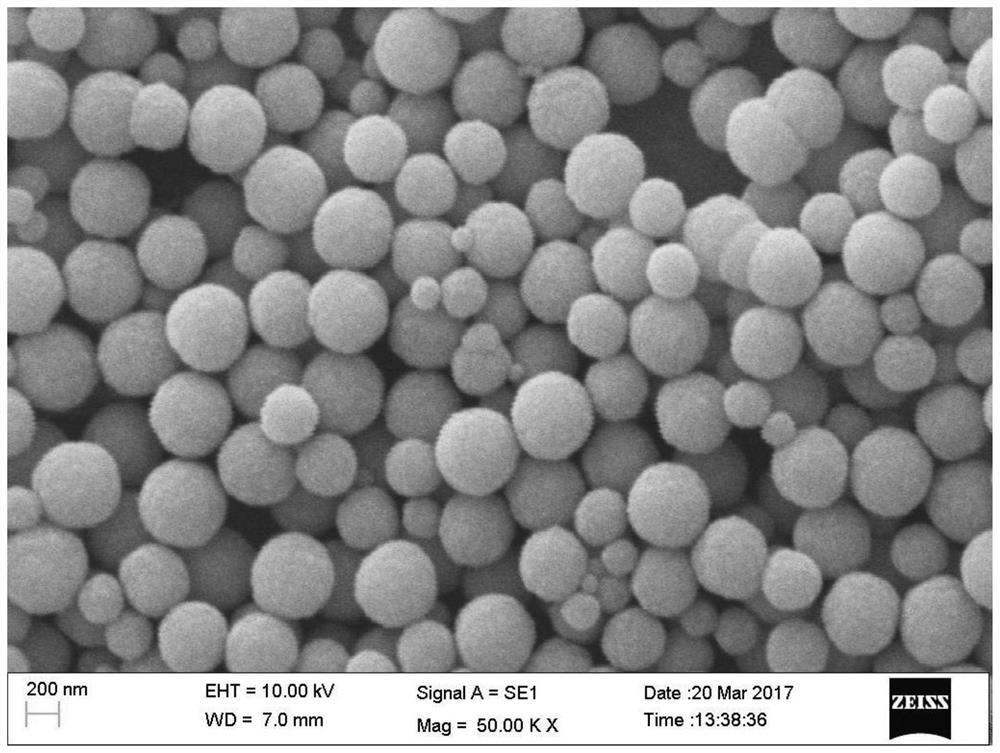

[0037] Embodiment 1: Preparation of ferric oxide nano-magnetic beads

[0038] The preparation process of ferroferric oxide nano-magnetic beads is referred to (Liu Chuanyong. The solvothermal preparation of magnetic ferroferric oxide microspheres and its silica coating research [D]. Qingdao University, 2014.), for the obtained four Fe3O3 nanoparticles were characterized by SEM, such as figure 1 As shown, the diameter is in the range of 100-500nm, which shows that the surface is round and smooth.

Embodiment 2

[0039] Embodiment 2: Preparation of nano magnetic beads modified by gold nanoparticles

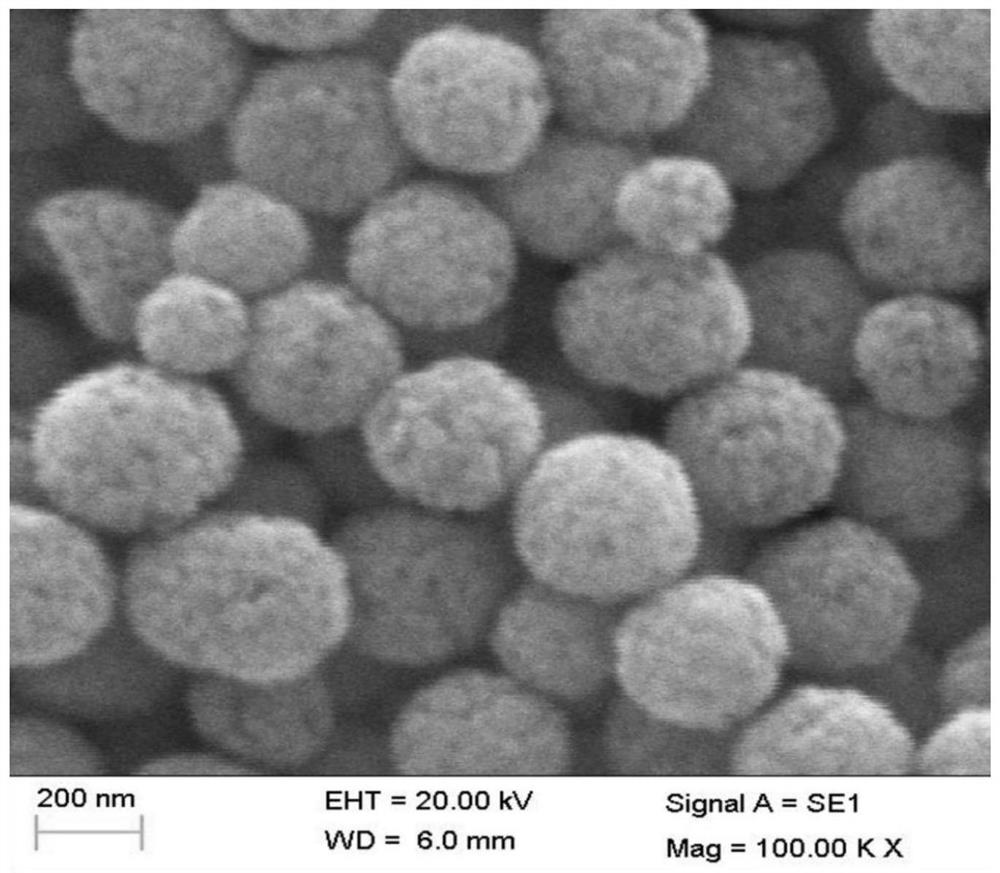

[0040] (1) Weigh 20mg of Fe3O4 nano-magnetic beads cleaned by 0.1M nitric acid ultrasonic rinse, add 10ml of glucose solution (0.5M), ultrasonically disperse and move into a hydrothermal kettle, tighten the tank, and move into an oven , heated to 160 degrees, reacted for 4 hours, took out and cooled to room temperature. After the supernatant was discarded, the bottom material was magnetically separated and washed with deionized water several times to remove impurities and obtain glycosylated nano-magnetic beads.

[0041] SEM characterization of glycosylation-modified nano-magnetic beads, such as figure 2 As shown, the diameter is 250nm ~ 400nm, and figure 1 Comparing the morphology of the Fe3O4 nano-magnetic beads in , it can be seen that there is obviously a layer of inclusions on the surface of the glycosylated magnetic beads.

[0042] (2) Disperse 20 mg of the above-mentioned glycos...

Embodiment 3

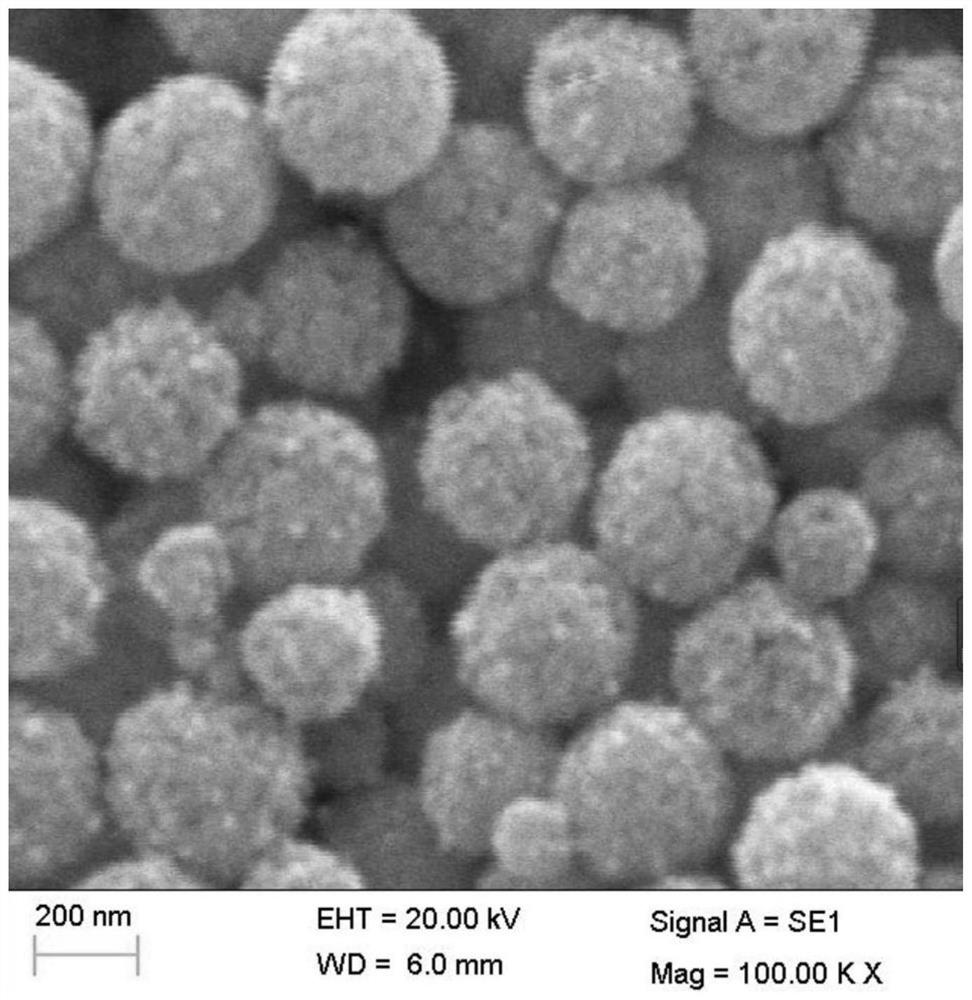

[0048] Embodiment 3: Preparation of nano magnetic beads modified by gold nanoparticles

[0049] Test with reference to Example 2, the difference is that step (1) is repeated twice, and the glycosylation modification is carried out twice, and the SEM of the nano magnetic beads modified by the gold nanoparticles of the gained is as follows: Figure 5 shown, with image 3 In comparison, the thickness of the glycosylation coating was significantly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com