A preparation method and application of amorphous manganese dioxide modified shrimp shell carbon matrix

A shrimp shell carbon base and manganese dioxide technology, applied in the field of electrocatalytic materials, can solve the problems of complex preparation process, unfriendly environment, long cycle, etc., and achieve the effects of simplifying the preparation process, being environmentally friendly, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] One embodiment of the present invention provides a method for preparing amorphous manganese dioxide modified shrimp shell carbon matrix, comprising the following steps:

[0037] Step 1: using EDTA aqueous solution to process the shrimp shell powder;

[0038] Step 2: pyrolyzing the shrimp shell powder treated in Step 1 in an inert atmosphere;

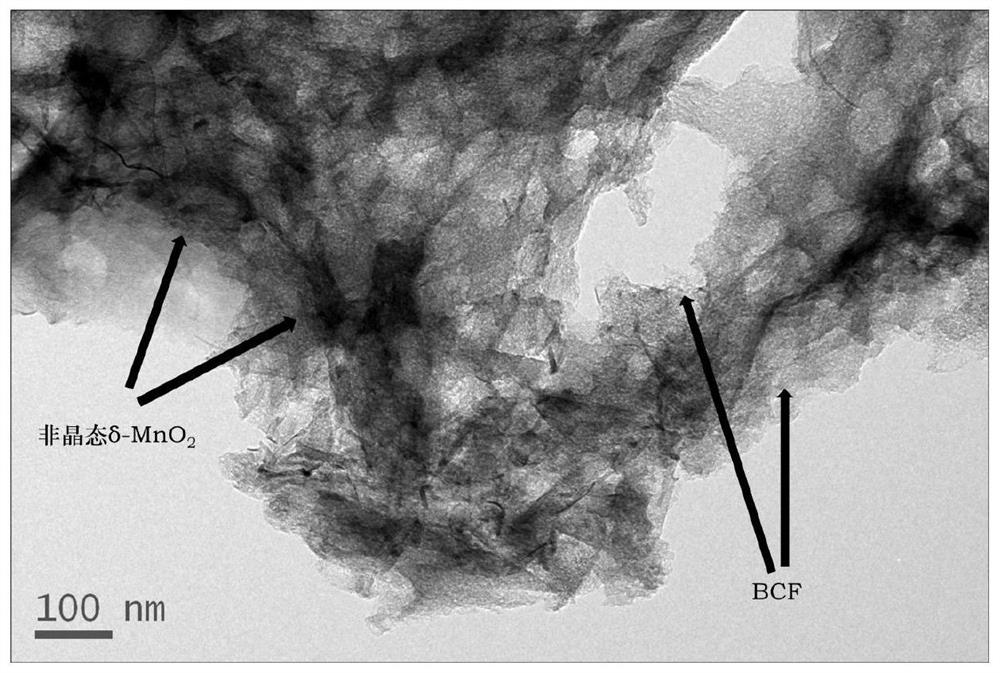

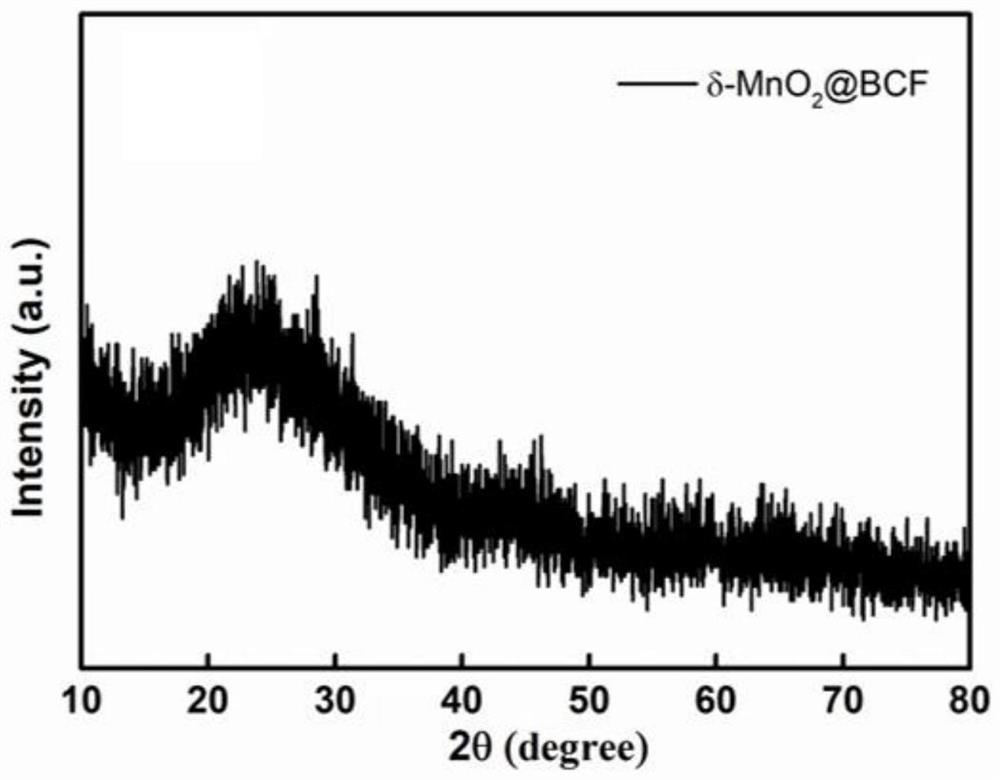

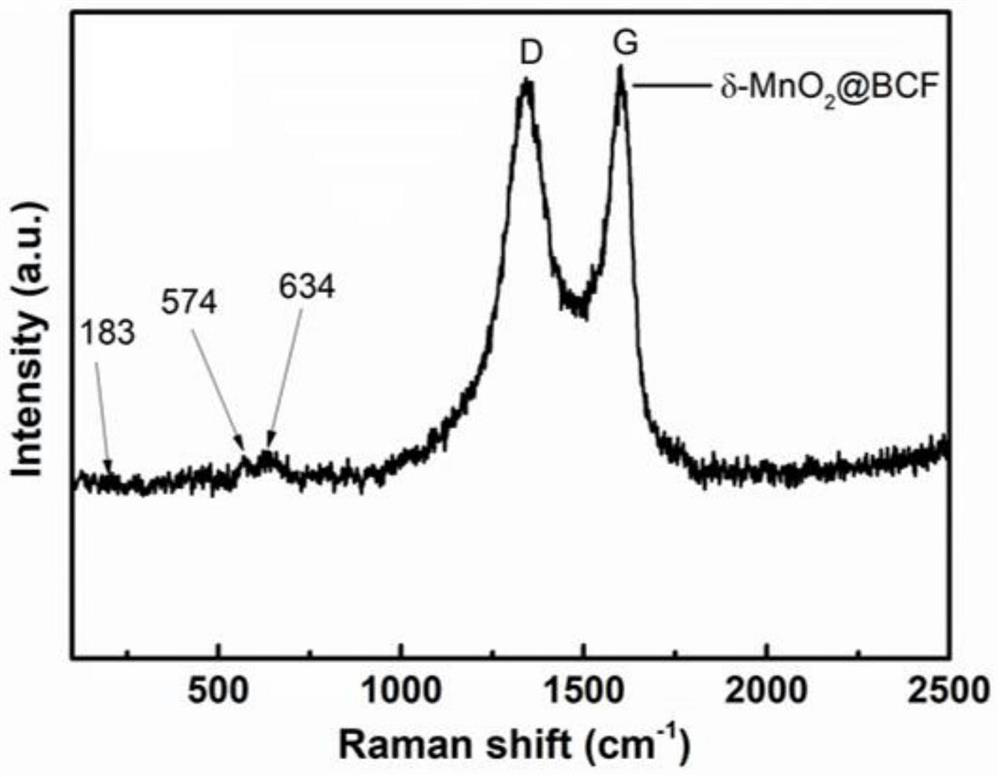

[0039] Step 3: The pyrolysis product is treated with potassium permanganate dilute acid solution, and the pyrolysis product after treatment with potassium permanganate dilute acid solution is dried to obtain amorphous manganese dioxide modified biomass carbon matrix composite material—δ -MnO 2 @BCF.

[0040] In one embodiment, before the first step, the method further includes: washing, drying and crushing the discarded shrimp shells into powder.

[0041] The impurity on the surface of the shrimp shell is removed by cleaning, so as to avoid the influence of the impurity on the performance of the subsequently prepared amorphous ma...

Embodiment 1

[0054] a. Add 3g of pretreated shrimp shell powder to 30mL of EDTA-2Na aqueous solution, the concentration of EDTA-2Na is 2%, the solid-liquid ratio is 1:10, and the solid-liquid separation is carried out after stirring for 0.5h

[0055] b. Dry the filter residue in step a and transfer it to a tube furnace for roasting under a nitrogen atmosphere, and naturally cool to room temperature, wherein the roasting temperature is 600°C, the holding time is 2.0h, and the heating program is 2°C / min;

[0056] c. Soak the pyrolysis product obtained in step b with dilute hydrochloric acid, add 0.15g of potassium permanganate, stir magnetically for 0.5h and let it stand for 20min, then wash it repeatedly with deionized water and ethanol, and dry it overnight at 60°C in a blast drying oven , to obtain a black amorphous manganese dioxide modified biomass carbon-based framework composite material, denoted as δ-MnO 2 @BCF;

[0057] d. Add dilute hydrochloric acid to the EDTA decalcification so...

Embodiment 2

[0059] a. Add 5g of pretreated shrimp shell powder to 75mL of EDTA-2Na aqueous solution, the concentration of EDTA-2Na is 3%, the solid-liquid ratio is 1:15, and the solid-liquid separation is carried out after stirring for 1.0h

[0060] b. Dry the filter residue in step a and transfer it to a tube furnace for roasting under a nitrogen atmosphere, and naturally cool to room temperature, wherein the roasting temperature is 900°C, the holding time is 2.5h, and the heating program is 3°C / min;

[0061] c. Soak the pyrolysis product obtained in step b with dilute nitric acid, add 0.5g potassium permanganate, stir magnetically for 0.5h and let stand for 30min, then wash repeatedly with deionized water and ethanol, and dry overnight at 60°C in a blast drying oven , to obtain a black amorphous manganese dioxide modified biomass carbon-based framework composite material, denoted as δ-MnO 2 @BCF;

[0062] d. Add dilute hydrochloric acid to the EDTA decalcification solution obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com