A kind of synthetic method of polynaphthylamine supported graphene

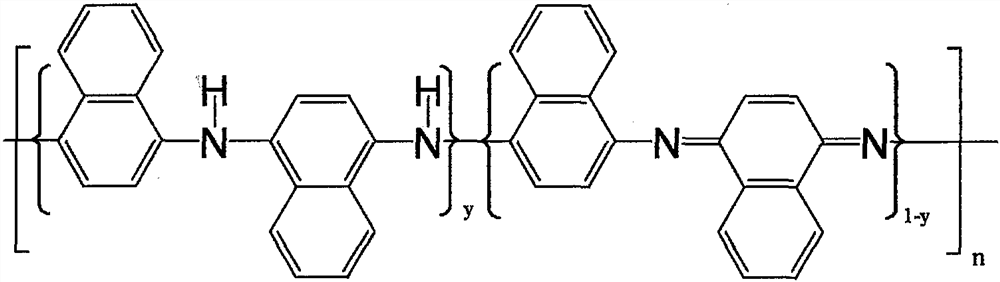

A synthesis method and technology of polynaphthylamine, applied in the field of material chemistry, can solve problems such as difficulty in achieving uniform modification of in-situ polymerization, poor dispersion of graphene materials, etc., and achieve good radiation stability and thermal stability, good sensitivity, and uniformity The effect of retouching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 0.01mol naphthylamine monomer and 0.02g graphite oxide into 50mL acidic aqueous solution, and ultrasonically disperse for 2h to obtain purple-brown sol (sol A), then dissolve 0.03mol ammonium persulfate in 50mL acidic aqueous solution, and slowly drip Add to sol A to obtain a mixed sol.

[0020] (2) Put the mixed sol obtained in step (1) into a 60°C heat-preserving device for a constant temperature stirring reaction for 24 hours to obtain a black precipitate;

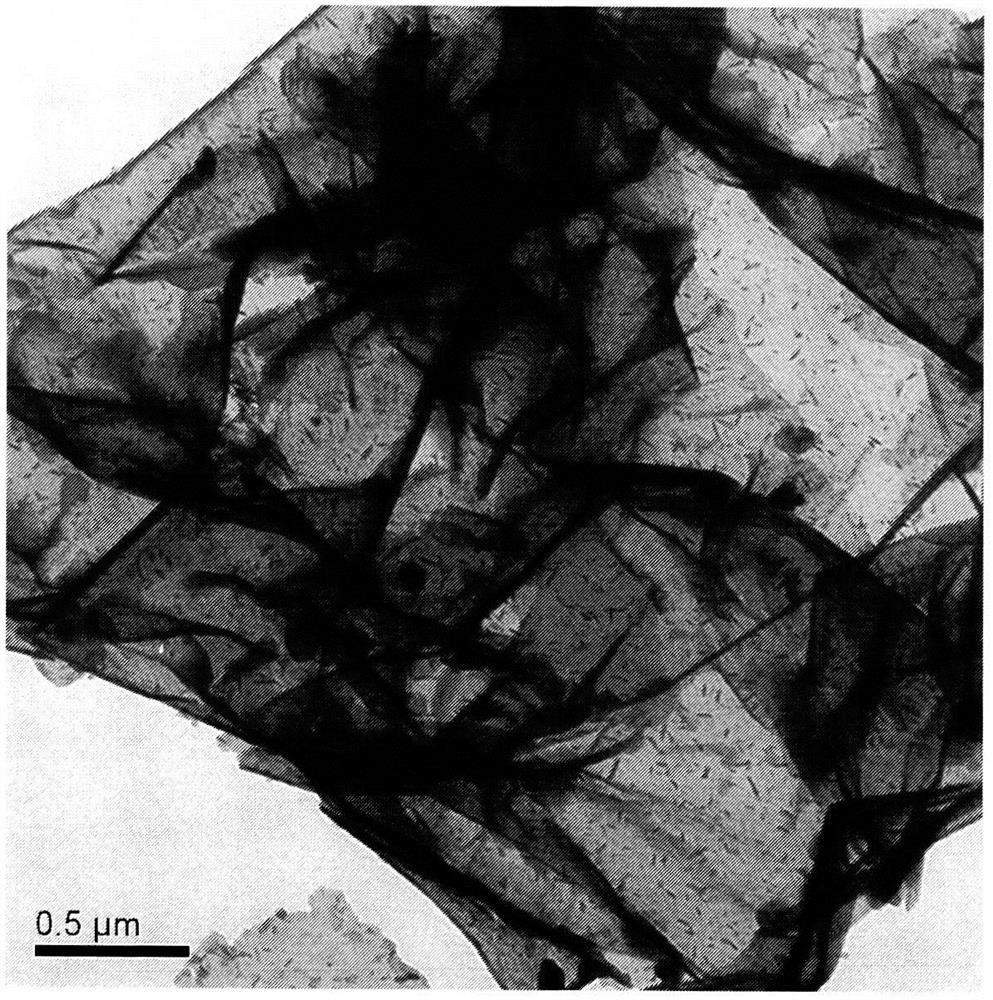

[0021] (3) Wash the black precipitate obtained in step (2) alternately with deionized water and ethanol. After each wash, use centrifuge precipitation or suction filtration equipment to filter, and then re-disperse the filtered product in deionized water or ethanol, and filter repeatedly Until the pH of the filtrate is 7, it is dried in a vacuum oven at 50°C to obtain the intermediate product polynaphthylamine supported graphene oxide powder;

[0022] (4) The obtained powder is irradiated with 160kGy electron b...

Embodiment 2,3

[0025] As a comparison:

[0026] Repeat the above example 1 without adding graphite oxide to obtain polynaphthylamine powder. The sensitivity of 1 ppm 30% toluene / 70% xylene mixed gas is 1.4.

[0027] Repeating the above example 1 without electron beam irradiation to obtain polynaphthylamine supported graphene oxide powder. The sensitivity of 1 ppm 30% toluene / 70% xylene mixed gas is 1.41.9.

[0028] The response of the comparative samples to benzene series is far lower than that of Example 1.

Embodiment 4

[0030] (1) Add 0.05mol naphthylamine monomer and 0.15g graphite oxide into 50mL acidic aqueous solution, and ultrasonically disperse for 2h to obtain purple-brown sol (sol A), then dissolve 0.05mol potassium persulfate in 50mL acidic aqueous solution, and slowly drip Add to sol A to obtain a mixed sol.

[0031] (2) The mixed sol obtained in step (1) was stirred and reacted at room temperature for 16 hours at a constant temperature to obtain a black precipitate;

[0032] (3) Wash the black precipitate obtained in step (2) alternately with deionized water and ethanol. After each wash, use centrifuge precipitation or suction filtration equipment to filter, and then re-disperse the filtered product in deionized water or ethanol, and filter repeatedly Until the pH of the filtrate is 7, dried in a vacuum oven at 80°C to obtain the intermediate product polynaphthylamine supported graphene oxide powder;

[0033] (4) The obtained powder is irradiated with 100 kGy electron beam to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com