Nanometer iron oxide modified carbon-based electrode and macroscopic-size large-scale preparation method and application thereof

A technology of nano-iron oxides and iron oxides, applied in chemical instruments and methods, battery electrodes, biochemical fuel cells, etc., can solve the problems of low electron transfer efficiency between electrodes and microorganisms, and limited performance of microbial electrochemical systems, achieving Enhance the effect of pollutant removal, improve electrochemical efficiency, and improve the effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A macro-scale large-scale preparation method of nano-iron oxide modified carbon-based electrode is completed according to the following steps:

[0033] Add FeCl to the solvent 3 ·6H 2 O and polyvinylpyrrolidone (PVPK30) are fully dissolved to obtain iron oxide precursor solution;

[0034] The concentration of the iron source (calculated as iron ions) in the iron oxide precursor solution is 100 mM;

[0035] The concentration of the carbon source in the iron oxide precursor solution is 20 g / L;

[0036] 2. High temperature heat treatment of electrodes

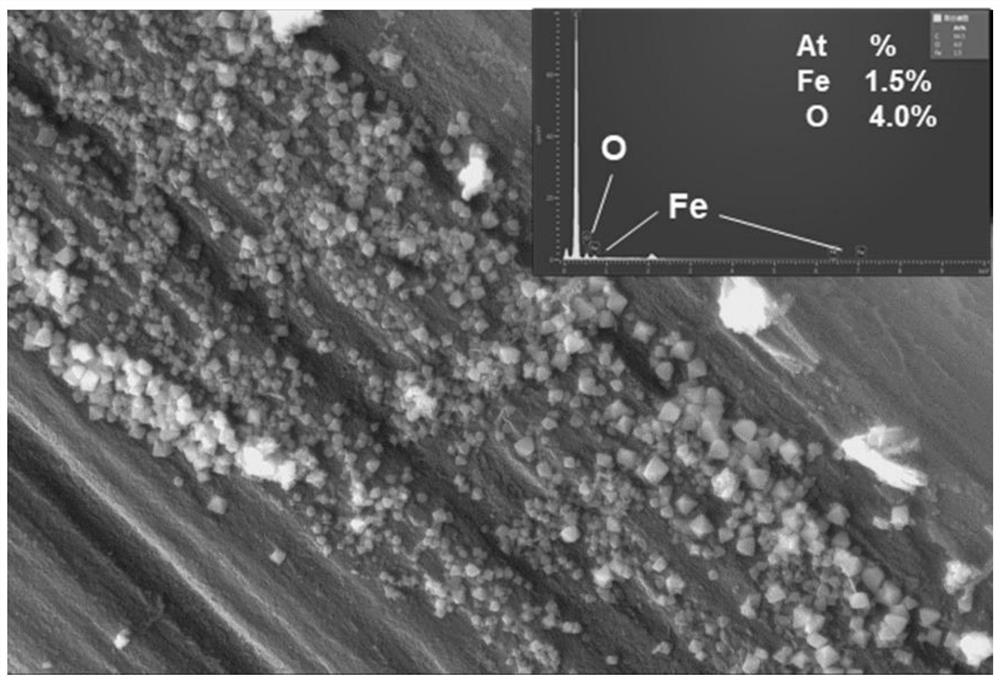

[0037] After the carbon cloth is fully washed with 10% hydrochloric acid and deionized water in sequence, it is fully soaked in the precursor solution prepared in step (1) and fully dried. The impregnated and dried carbon cloth is wrapped and sealed with aluminum foil paper, placed in a muffle furnace, and subjected to heat treatment to obtain nano-iron oxide modified carbon cloth, denoted as FeCl 3 - Carbon cloth.

...

Embodiment 2

[0041]A macro-scale large-scale preparation method of nano-iron oxide modified carbon-based electrode is completed according to the following steps:

[0042] Add FeCl to the solvent 3 ·6H 2 O and polyvinylpyrrolidone (PVPK30) are fully dissolved to obtain iron oxide precursor solution;

[0043] The concentration of the iron source (calculated as iron ions) in the iron oxide precursor solution is 100 mM;

[0044] The concentration of the carbon source in the iron oxide precursor solution is 20 g / L;

[0045] 2. High temperature heat treatment of electrodes

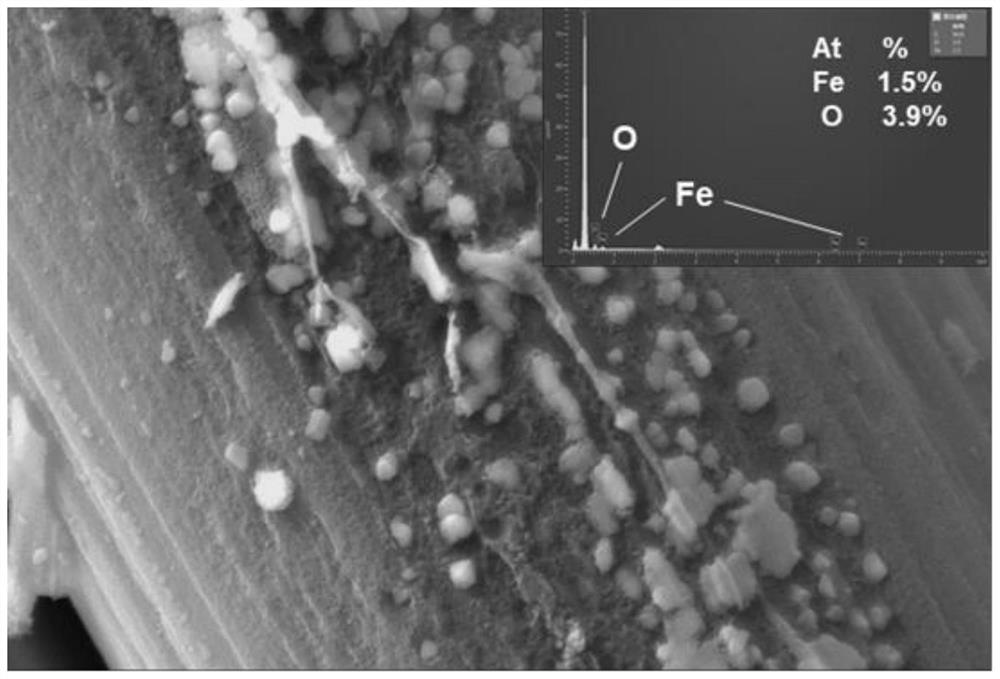

[0046] After the carbon brush is fully cleaned with 10% hydrochloric acid and deionized water in sequence, it is fully soaked in the precursor solution prepared in step (1) and fully dried. The impregnated and dried carbon brush is wrapped and sealed with aluminum foil paper, placed in a muffle furnace, and heat treated to obtain a carbon brush modified by nano-iron oxide, denoted as FeCl 3 - Carbon brushes.

[0047] T...

Embodiment 3

[0050] A macro-scale large-scale preparation method of nano-iron oxide modified carbon-based electrode is completed according to the following steps:

[0051] Add Fe(NO) to the solvent 3 ) 3 ·9H 2 O and polyvinylpyrrolidone (PVPK30) are fully dissolved to obtain iron oxide precursor solution;

[0052] The concentration of the iron source (calculated as iron ions) in the iron oxide precursor solution is 100 mM;

[0053] The concentration of the carbon source in the iron oxide precursor solution is 20 g / L;

[0054] 2. High temperature heat treatment of electrodes

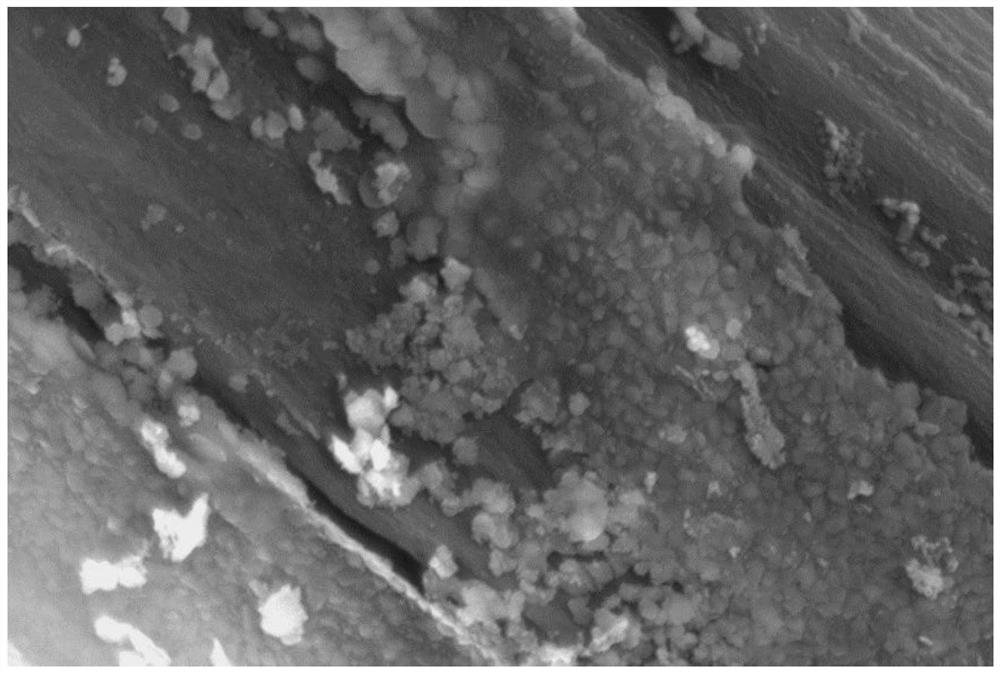

[0055] After the carbon cloth is fully washed with 10% hydrochloric acid and deionized water in sequence, it is fully soaked in the precursor solution prepared in step (1) and fully dried. The impregnated and dried carbon cloth is wrapped and sealed with aluminum foil paper, placed in a muffle furnace, and subjected to heat treatment to obtain nano-iron oxide modified carbon cloth, denoted as Fe(NO 3 ) 3 - Carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com