Drilling oil-containing wastewater treatment device

A technology for wastewater treatment and drilling, which is applied in the field of oily sewage treatment in oil fields, can solve the problems of unsatisfactory treatment effect and high treatment cost, and achieve the effects of good social and economic benefits, simplified process and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

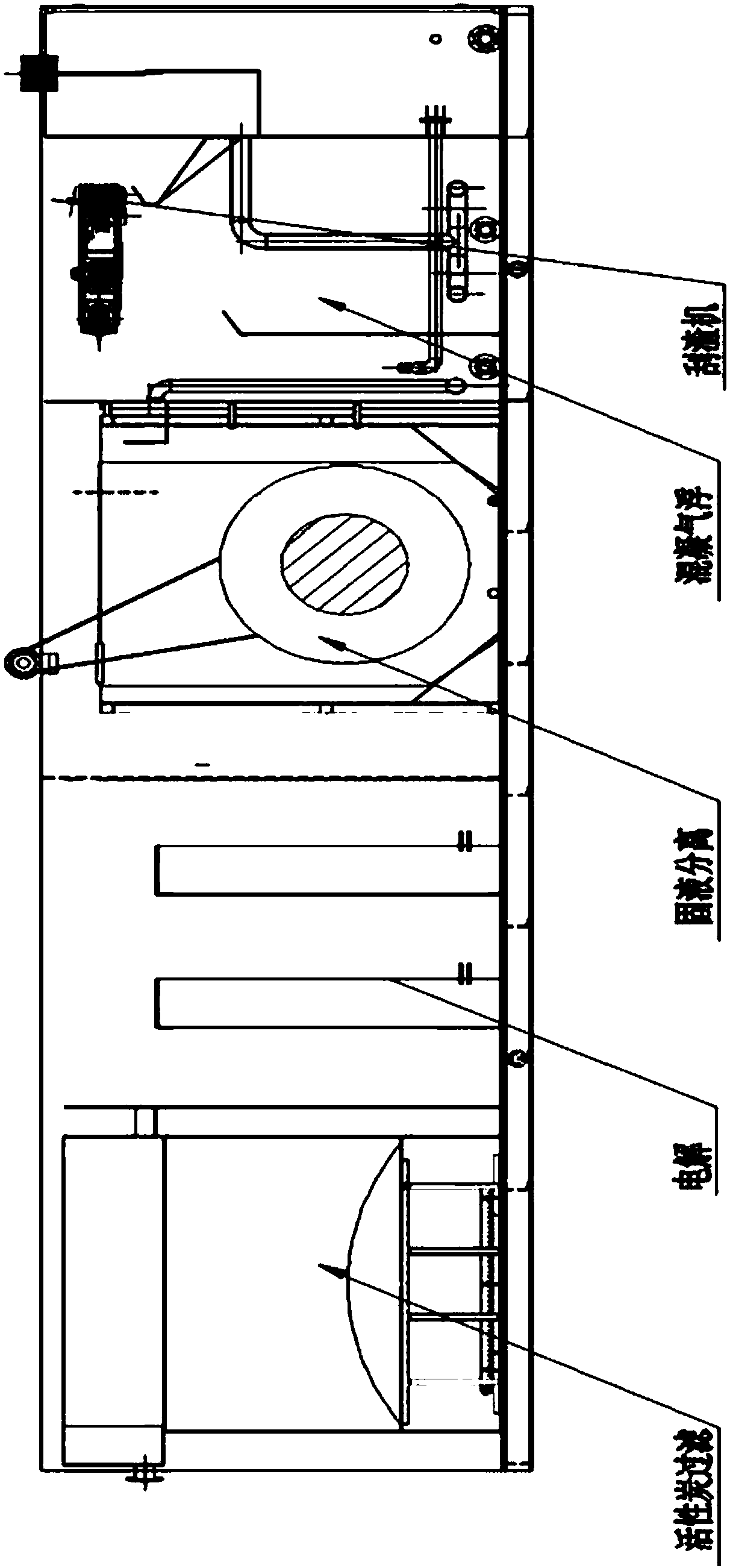

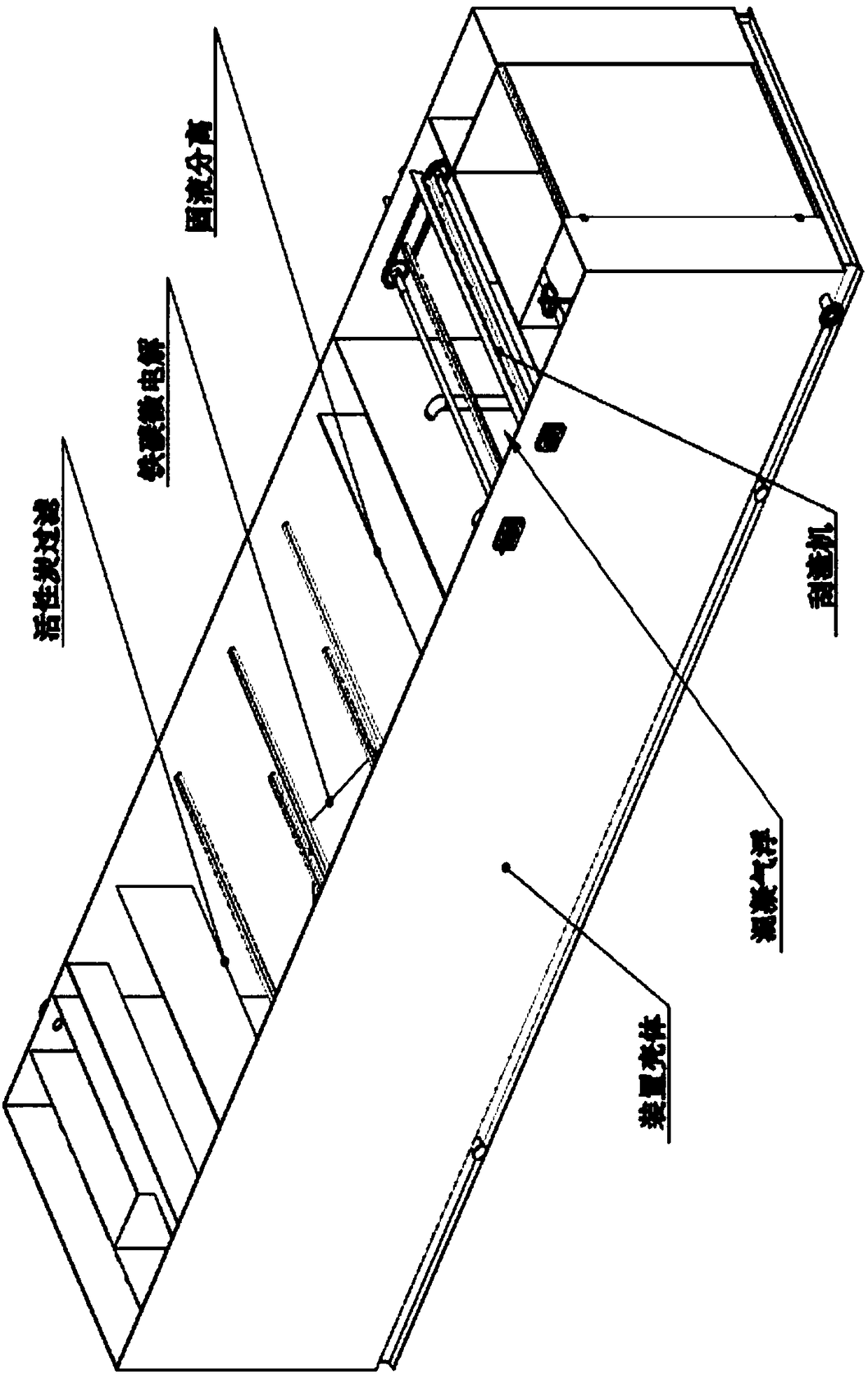

[0020] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

[0021] (1) The incoming water is firstly adjusted for water quality, and then separated and removed by gravity sedimentation to remove most of the coarse suspended solids and slick oil in the wastewater;

[0022] (2) The homogenized sewage flows to the coagulation and sedimentation treatment unit, and the pH of the water is adjusted to 8-10 by adding lime milk, and then 50-500mg / L of polyaluminum chloride and 1-10mg / L of For polyacrylamide, the flocs produced are removed by air flotation, and the suspended solids with high density are removed by gravity sedimentation;

[0023] (3) The coagulation and sedimentation effluent enters the fiber rotary fruit filter device to further remove suspended solids in the water;

[0024] (4) The wastewater treated in step (3) is oxidized to remove COD and ammonia nitrogen and reduce heavy metals through electrolysis;

[0025...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com