A method for monomer copolymerization to promote ip-1-b to form i' crystal directly from melt

A technology of ip-1-b and copolymerization, which is applied in the field of promoting iP-1-B to form I' crystals directly from the melt by the copolymerization of a small amount of monomers, can solve the problems of changing the crystal form, restricting comprehensive mechanical properties, and being difficult to achieve. The effect of less comonomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

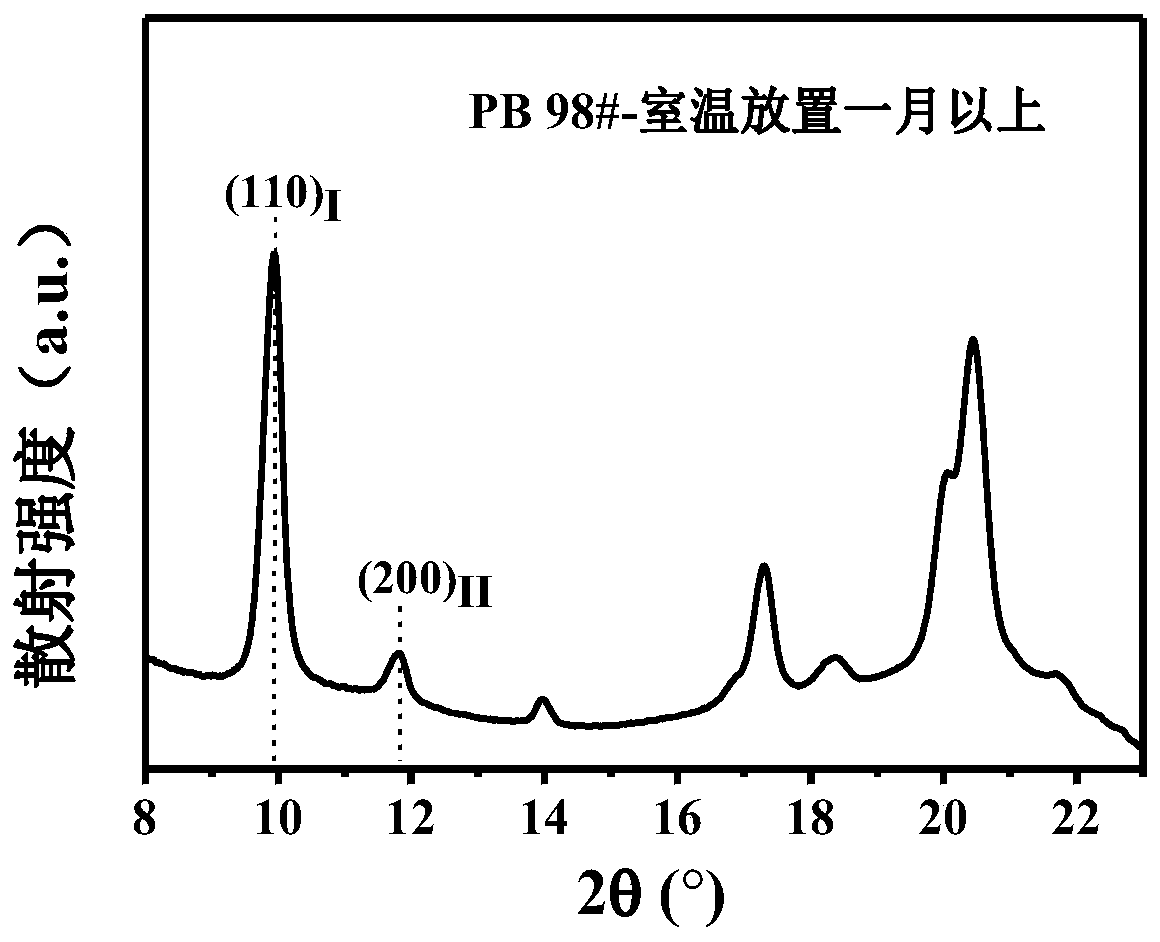

[0027] Weigh 7g of iP-1-B98# (Shandong Dongfang Hongye Chemical Co., Ltd., copolymerized iP-1-B, with an identical mass fraction of 98%, and a melt flow rate (MFR) of 1.31g / 10min (190°C / 2.16kg), propylene feed percentage 3-5%), preheated with a flat vulcanizer at 180°C for 10 minutes, then gradually increased the pressure to 25MPa by gradually increasing pressure, kept at the highest pressure for 3 minutes, and then cold pressed at 25MPa 8 minutes, pressed into a 0.5mm thick sheet sample, took it out and left it at room temperature for 30 days (24×30 hours), so that the formed II crystal was basically transformed into I crystal, as shown in the attached figure 1 shown.

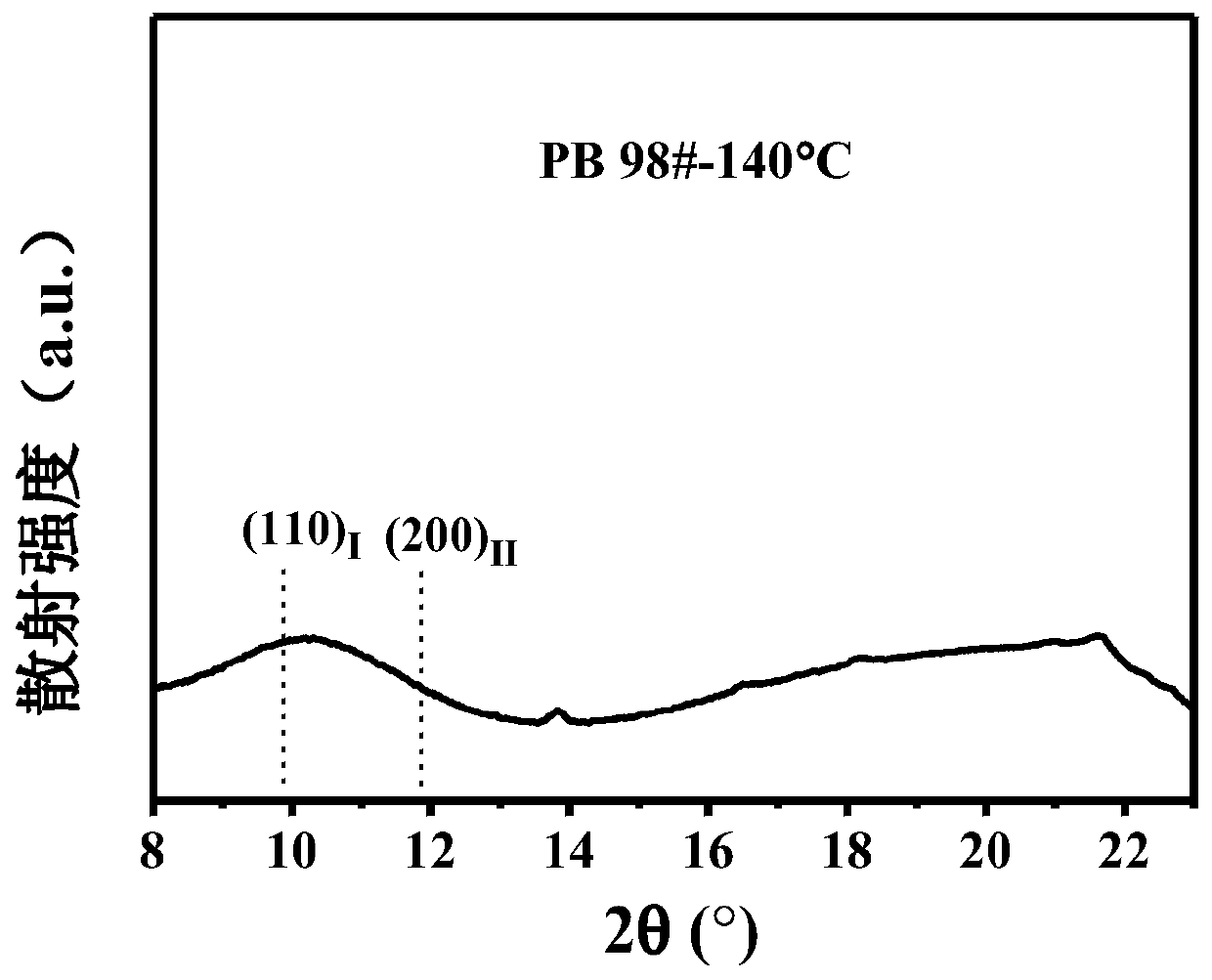

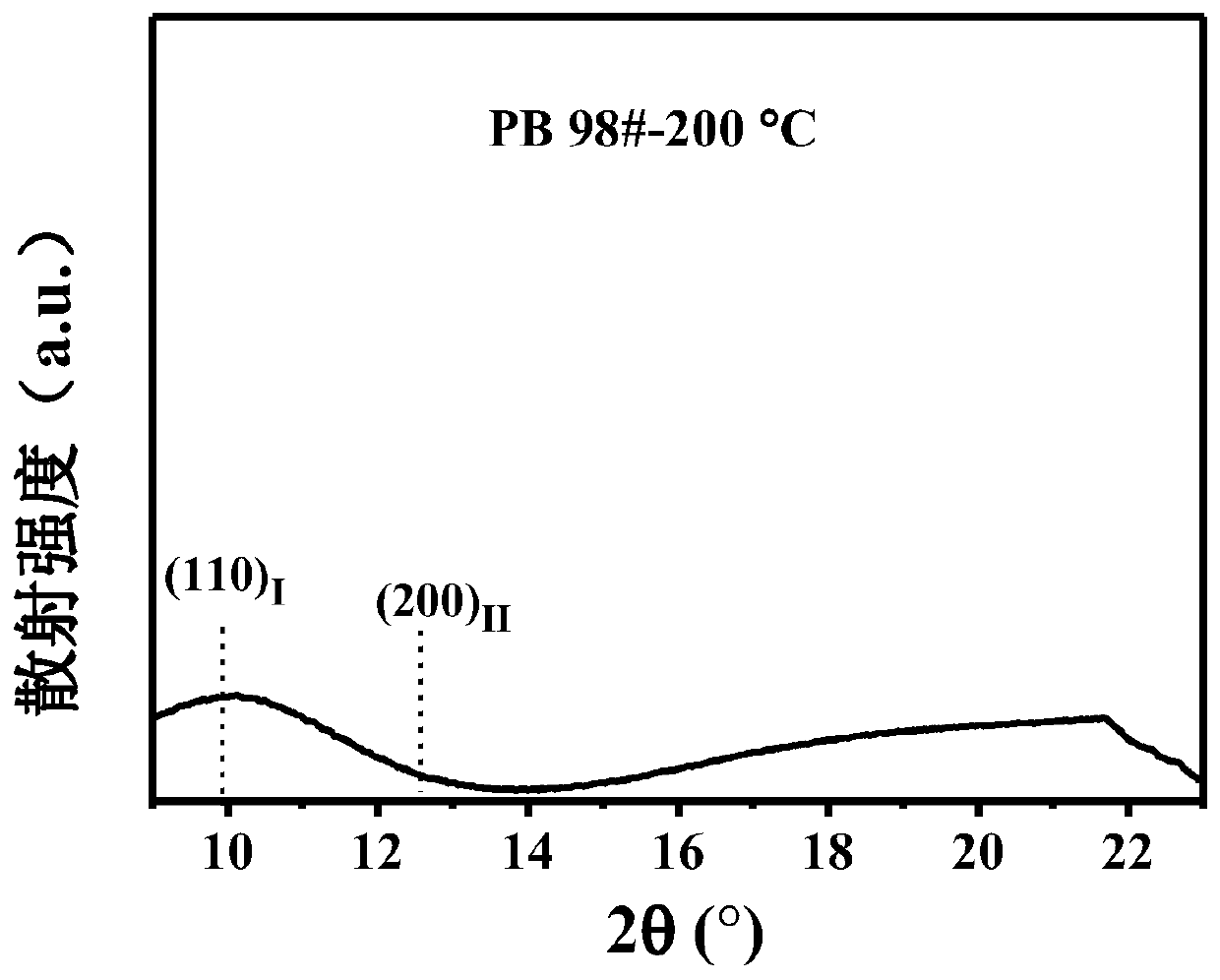

[0028] Cut the sample into 1mm 2 Large and small square flakes, wrapped in aluminum foil, controlled by linkam hot stage, using a heating rate of 5°C / min, observing the melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com