Solvent-free epoxy coating for high-pressure airless spraying on outer wall of buried steel pipe and preparation method thereof

A high-pressure airless, epoxy coating technology, used in the coating field, can solve the problems of poor coating toughness and sag resistance, and achieve the effects of excellent toughness and sag resistance, viscosity recovery, and good sag resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

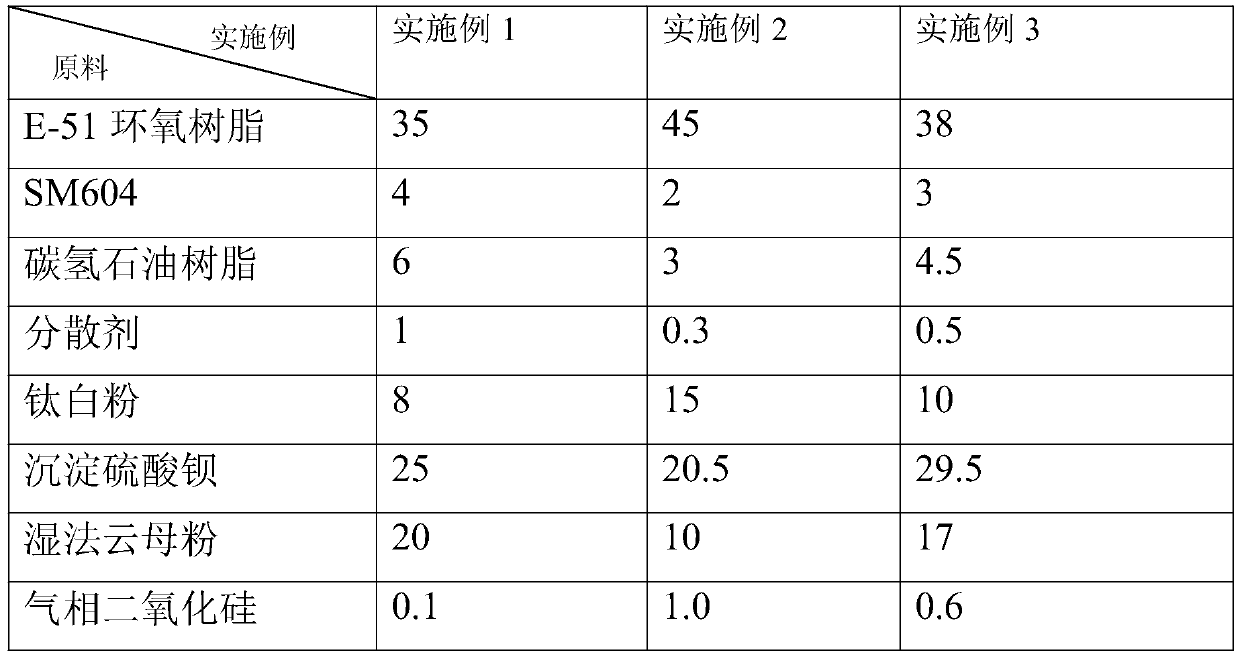

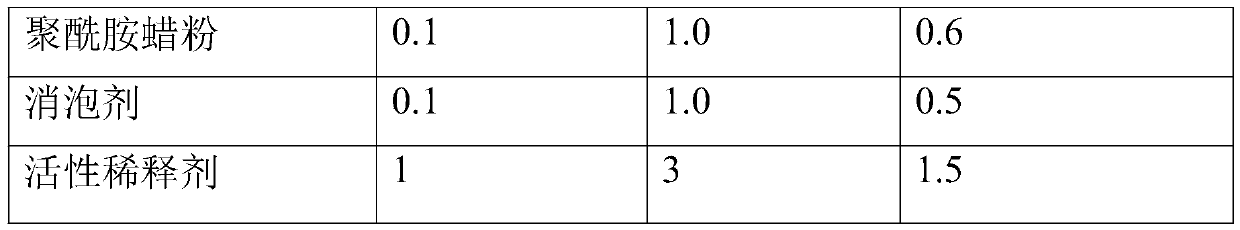

[0044] The weight composition of component A of solvent-free epoxy coating for high-pressure airless spraying on the outer wall of buried steel pipe is shown in the following table:

[0045]

[0046]

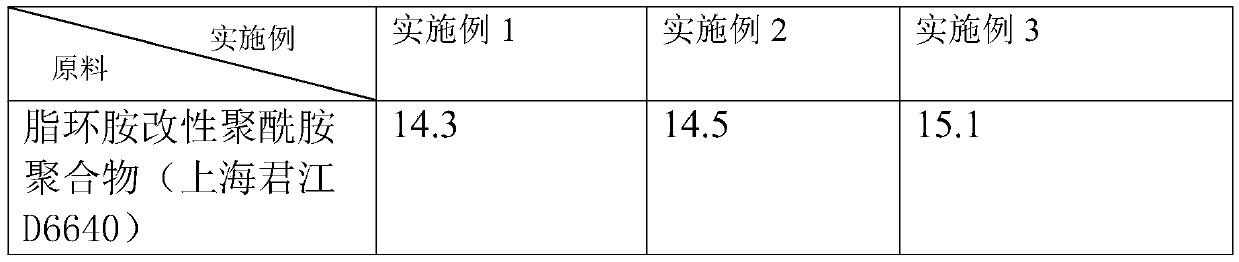

[0047] The weight composition of component B raw materials of solvent-free epoxy coating for high-pressure airless spraying of the outer wall of buried steel pipe is shown in the following table:

[0048]

[0049] The solvent-free epoxy coating for the high-pressure airless spraying of the outer wall of the buried steel pipe of embodiment 1-3 is prepared by the following method:

[0050] Add E-51 epoxy resin, SM604, hydrocarbon petroleum resin, dispersant, titanium dioxide, precipitated barium sulfate, wet-process mica powder, anti-sedimentation aid, defoamer, and reactive diluent into the mixing tank in sequence according to the raw material formula , 1200r / min high-speed stirring for 30min, pour into a three-roller mill for grinding, the grinding temperature is 50°C-7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com