Coil-structure electrothermal evaporation hollow fabric, manufacturing method and application

An electrothermal evaporation and coil technology, which is applied in fabrics, multi-strand fabrics, textiles and papermaking, etc., can solve the problems of small equipment operation flexibility, low water recovery rate, and large power consumption, so as to improve water evaporation efficiency and good heat insulation and water conductivity, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

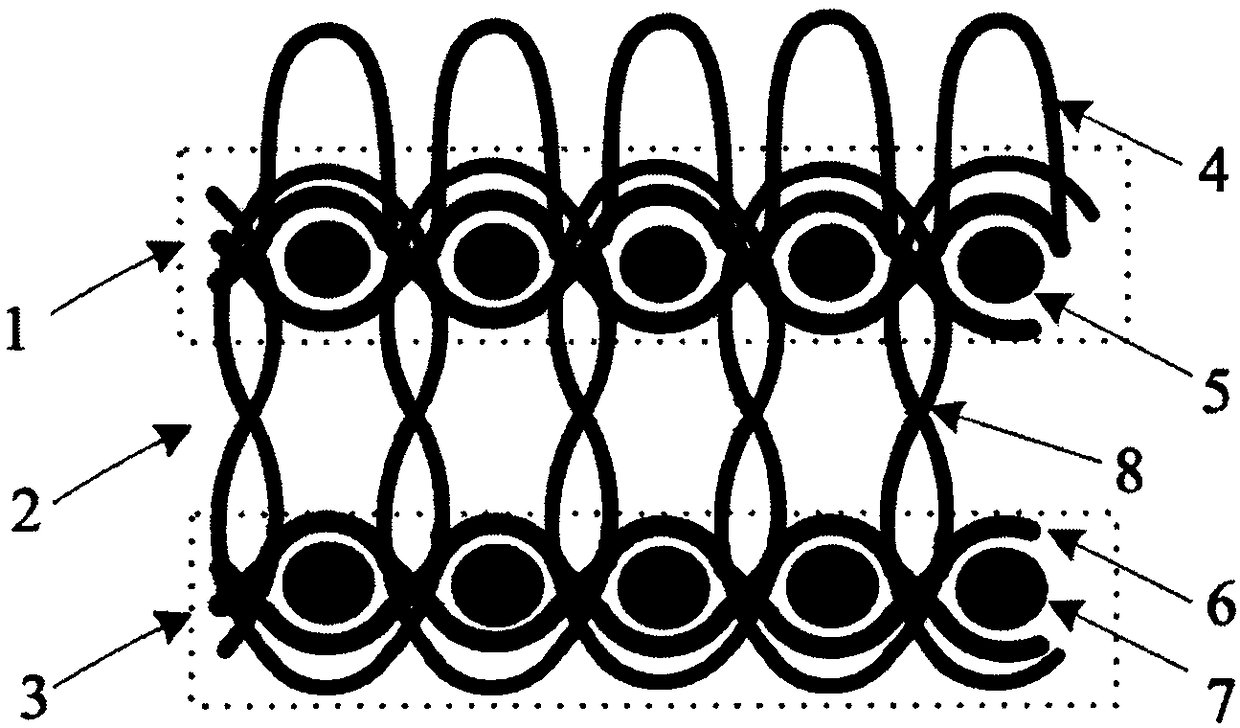

[0030] A kind of electrothermal evaporation hollow fabric based on carbon fiber coil structure disclosed in this embodiment selects T-300 carbon fiber (Toray Company, 12K) as the conductive fiber, and selects cotton fiber air textured yarn with a fineness of 30 as the water-absorbing fiber. Arranged at intervals, the ratio of fiber root number is 1:1, as warp 4 and weft 5 to weave electrothermal evaporation layer 1; select 1000tex polyethylene fiber as warp 6 and weft 7 to weave floating layer 3; select 20 cotton yarns as hydrophilic fiber and The 100D polyester monofilament is used as the support fiber, and the two are arranged at intervals, and the fiber root ratio is 1:1 as the spacer yarn 8 to weave the heat-insulating and water-conducting layer 2; the fabric width is set to 10 cm, and the warp and weft density: 10 threads / cm; Yarn density: 10 threads / cm.

[0031] Weaving process:

[0032] The first step is to start the weft insertion device to introduce the weft yarn of ...

Embodiment 2

[0040] A coil structure electrothermal evaporation hollow fabric based on nickel-plated carbon fiber disclosed in this embodiment selects nickel-plated carbon fiber (Suzhou Jiedi Nano Technology Co., Ltd., 12K) as the conductive fiber; Arranged at intervals, the ratio of fiber root number is 1:1, as warp yarn 4 and weft yarn 5 weaving electrothermal evaporation layer; polyethylene fiber of 600tex is selected as warp yarn 6, and a polypropylene plastic tube with a diameter of 4 mm at both ends (hollowness 80%) ) as weft yarn 7, weave floating layer 3; select 1000tex hydrophilic modified polyester bulky yarn as hydrophilic fiber and 50D polyester monofilament as supporting fiber, arrange at intervals, fiber number ratio 1:2, as spacer yarn 8 Weaving heat-insulating and water-conducting layer 2; setting fabric width to 10 cm, warp and weft density: 8 threads / cm; spacer yarn density: 8 threads / cm.

[0041] Weaving process:

[0042] The first step is to start the weft insertion de...

Embodiment 3

[0050] A coil structure electrothermal evaporation hollow fabric based on carbon nanotube yarn disclosed in this embodiment selects a carbon nanotube film winding yarn (Suzhou Jiedi Nano Technology Co., Ltd.) with a diameter of 0.8 mm as the conductive fiber, and 1500tex hydrophilic modification Polyester fiber bulked yarn is used as water-absorbing and evaporating fibers, and the two are arranged at intervals, and the fiber root ratio is 1:1. It is used as warp yarn 4 and weft yarn 5 to weave the electric heating evaporation layer; 1500tex polyethylene fiber is used as warp yarn 6 and weft yarn 7 to weave the floating layer 3 The ramie fiber with a fineness of 20 is selected as the water-conducting fiber, and the polypropylene monofilament of 150D is used as the supporting fiber. Set fabric width to 10 cm, warp and weft density: 6 threads / cm; spacer yarn density: 6 threads / cm.

[0051] Weaving process:

[0052] The first step is to start the weft insertion device to introduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com