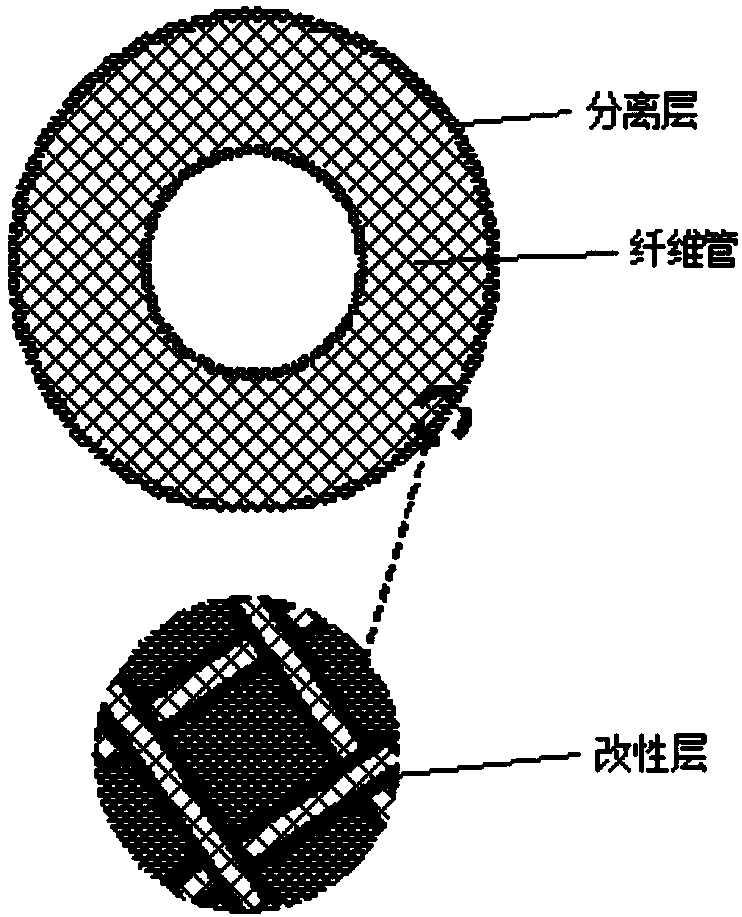

Hollow braided pipe modification method and hollow fiber film preparation method

A braided tube and hollow technology, which is applied in the field of polymer hollow fiber membrane preparation, can solve the problems of easy falling off, poor mechanical strength, and poor adhesion, and achieve the effects of improving adhesion, uniform distribution, and enhancing interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] 1) Immerse a polyester fiber hollow braided tube with an inner diameter of 1.0mm and an outer diameter of 1.7mm in a 5wt% sodium hydroxide solution, treat it at 50°C for 30min, and then wash it with deionized water at a speed of 3000 rpm Centrifuge for 5 minutes and dry at 80°C.

[0060] 2) configure a Tris buffer solution with pH 8.5, mix it uniformly with dopamine and polyethyleneimine, and prepare a modified solution whose dopamine concentration is 4.0wt% and polyethyleneimine concentration is 10wt%; The tube was dipped into the modification solution for one coating, treated at 60° C. for 30 minutes, washed with deionized water, and dried by centrifugation.

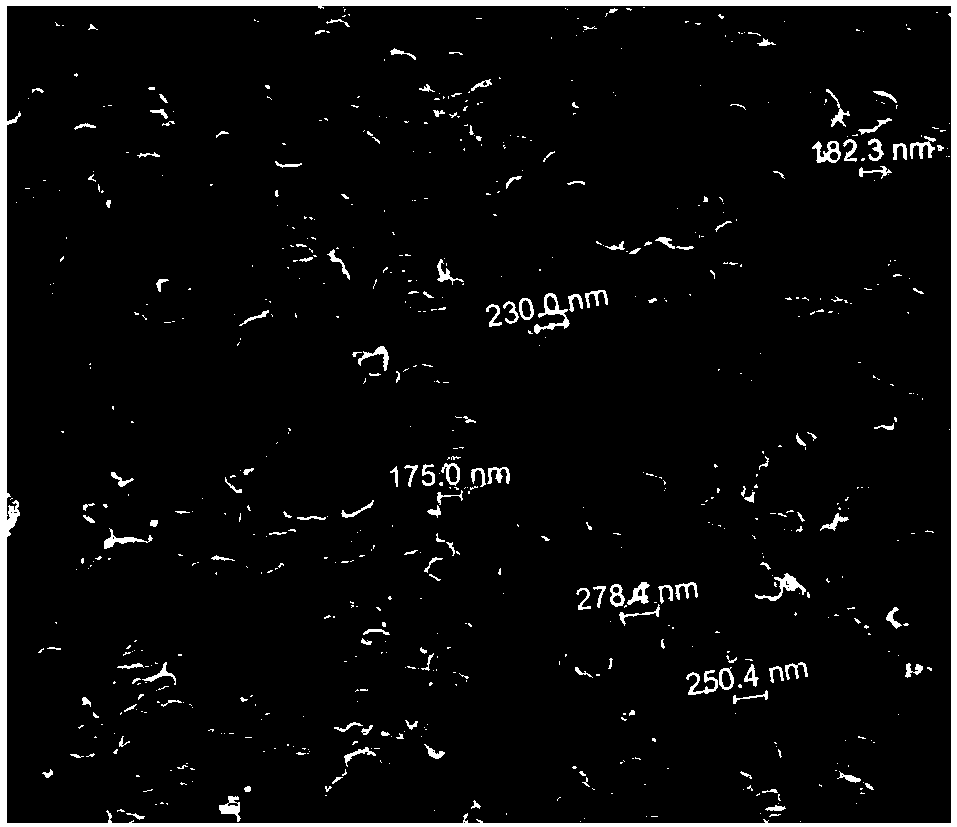

[0061] 3) Soak the braided tube after the above treatment in 2% CaCl 2 Mineralization was carried out in the solution, and treated at room temperature (25°C) for 8 hours to grow nanoparticles (25.6±3.6nm) on the surface of the braided tube; after washing with deionized water, dry at a temperature of 60°C.

[0...

Embodiment 2

[0071] 1) Immerse a nylon fiber braided tube with an inner diameter of 1.0mm and an outer diameter of 1.7mm in 7.5wt% sodium hydroxide solution, treat it at 45°C for 20min, then wash it with deionized water, and centrifuge at a speed of 5000 rpm 10min, dry at 80°C.

[0072] 2) Configure a Tris buffer solution with a pH of 8.5, uniformly mix it with dopamine and diethylenetriamine to prepare a modified solution with a dopamine concentration of 8.0wt% and a diethylenetriamine concentration of 15wt%; Immerse in the modification solution for one coating, treat at 70° C. for 20 minutes, wash with deionized water, and spin dry by centrifugation.

[0073] 3) Soak the braided tube after the above treatment in 3wt% AgNO 3 Mineralization was carried out in the solution, and treated at room temperature (25°C) for 7 hours to grow nanoparticles (16.4±2.6nm) on the surface of the braided tube; after washing with deionized water, dry at a temperature of 70°C.

[0074] 4) Under the conditio...

Embodiment 3

[0083] 1) Immerse a nylon fiber hollow braided tube with an inner diameter of 1.0mm and an outer diameter of 1.7mm in a 10wt% sodium hydroxide solution, treat it at a temperature of 50°C for 15min, then wash it with deionized water, and centrifuge at a speed of 8000 rpm 10min, dry at 80°C.

[0084] 2) configure the Tris buffer solution with pH 8.5, uniformly mix it with tannic acid and diethylenetriamine to obtain a modified solution whose concentration of tannic acid is 5wt% and diethylenetriamine concentration is 10wt%; The finished braided tube was dipped into the modification solution for one coating, treated at 60° C. for 40 minutes, washed with deionized water, and dried by centrifugation.

[0085]3) Soak the braided tube after the above treatment in 5wt% FeCl 2 Mineralize in the solution, and treat at room temperature (25°C) for 6h to grow nanoparticles (13.8±2.2nm) on the surface of the braided tube; after washing with deionized water, dry at 60°C.

[0086] 4) Under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com