Preparation method of shape memory polymer with two-stage ultraviolet-light reversible curable lock

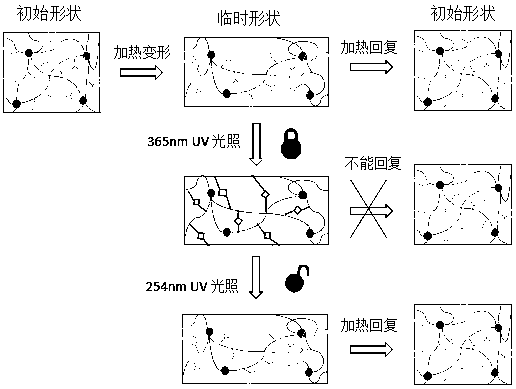

A memory polymer, ultraviolet light technology, applied in the field of intelligent polymer materials, can solve the problems of energy waste, unapplied shape memory polymer materials, poor shape memory performance of shape memory materials, etc. performance, improve the effect of mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

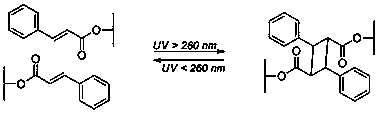

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a method for preparing a shape memory polymer with a two-stage ultraviolet light reversible curing lock. The specific steps of the method are as follows:

[0022] (1) Stir and dissolve 1.90g of diethyl iminodiacetate and 1.66g of cinnamoyl chloride in dichloromethane to obtain a uniform solution, add 2.5mL of triethylamine, react at 20°C for 6h, and then use hydrochloric acid and carbonic acid in sequence Sodium hydrogen solution, deionized water washing, drying, to obtain monomeric compounds containing cinnamon structural units;

[0023] (2) Add 1.25 g of 1,4-cyclohexanedimethanol and 27.5 μL of stannous octoate to 2.50 g of monomeric compounds containing cinnamon structural units, and react under vacuum at 120°C for 24 hours to obtain a shape containing hydroxyl groups at both ends memory polymer prepolymer;

[0024] (3) Dissolve 2.5 g of shape memory polymer prepolymer containing hydroxyl groups at both ends in chloroform, add 0.075 g of acr...

Embodiment 2

[0028] This embodiment provides a method for preparing a shape memory polymer with a two-stage ultraviolet light reversible curing lock. The specific steps of the method are as follows:

[0029] (1) Stir and dissolve 1.90g of diethyl iminodiacetate and 1.66g of cinnamoyl chloride in dichloromethane to obtain a uniform solution, add 2.5mL of triethylamine, react at 20°C for 6h, and then use hydrochloric acid and carbonic acid in sequence Sodium hydrogen solution, deionized water washing, drying, to obtain monomeric compounds containing cinnamon structural units;

[0030] (2) Add 1.25 g of 1,4-cyclohexanedimethanol and 27.5 μL of stannous octoate to 2.50 g of monomeric compounds containing cinnamon structural units, and react under vacuum at 120°C for 24 hours to obtain a shape containing hydroxyl groups at both ends memory polymer prepolymer;

[0031] (3) Dissolve 2.5 g of shape memory polymer prepolymer containing hydroxyl groups at both ends in chloroform, add 0.14 g of isoc...

Embodiment 3

[0035] This embodiment provides a method for preparing a shape memory polymer with a two-stage ultraviolet light reversible curing lock. The specific steps of the method are as follows:

[0036] (1) Stir and dissolve 1.90g of diethyl iminodiacetate and 1.66g of cinnamoyl chloride in dichloromethane to obtain a uniform solution, add 2.5mL of triethylamine, react at 20°C for 6h, and then use hydrochloric acid and carbonic acid in sequence Sodium hydrogen solution, deionized water washing, drying, to obtain monomeric compounds containing cinnamon structural units;

[0037] (2) Add 1.255 g of 1,8-octanediol and 27.5 μL of stannous octoate to 2.50 g of the above monomer compound, and react in a vacuum environment at 120°C for 24 hours to obtain a prepolymerized shape memory polymer containing hydroxyl groups at both ends. thing;

[0038](3) Dissolve 2.5 g of the above-mentioned prepolymer containing terminal hydroxyl groups in chloroform, add 0.08 g of acryloyl chloride and 0.5 mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com