Hard clear, easy-to-clean hydrophobic coating for wood, metal and plastic surfaces

A hydrophobic coating, high hardness technology, used in alkali metal silicate coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problem of wear resistance, alkali resistance, high temperature resistance, high humidity resistance, and difficult to clean metal surfaces. Oil contamination, reduced easy-to-clean coating performance, etc., to achieve good hydrophobicity, improved curing effect, and excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

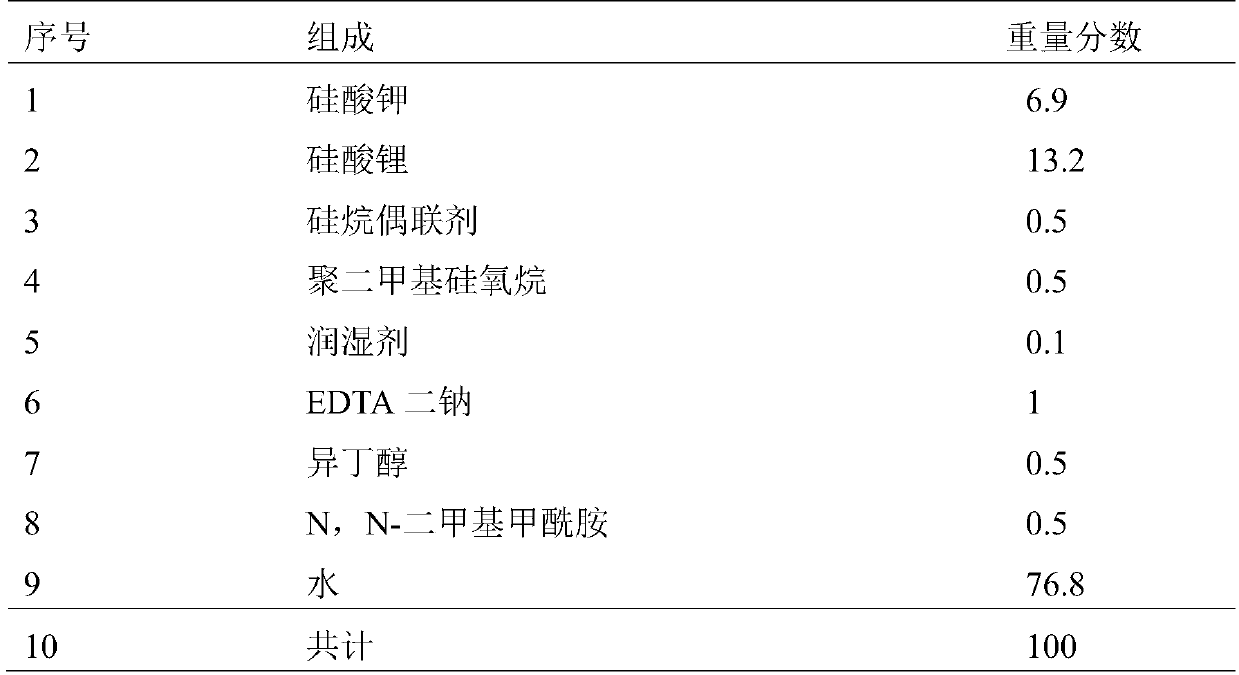

[0039] formula:

[0040] Table 1 Embodiment 1 formula

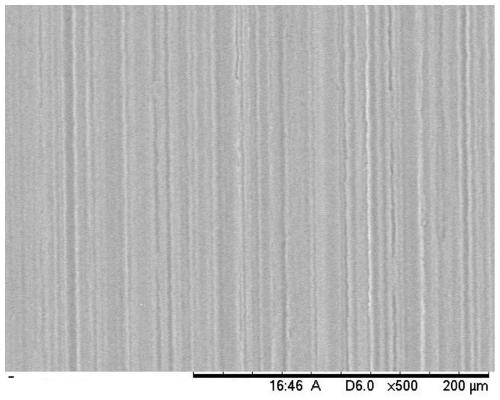

[0041]

[0042] In high-hardness transparent and easy-to-clean hydrophobic coatings used on wood, metal and plastic surfaces, potassium silicate and lithium silicate exist in the form of aqueous solutions respectively, wherein the mass percentage concentration of lithium silicate aqueous solution is 25%, and the mass percentage concentration of potassium silicate aqueous solution is 50%.

[0043] Preparation process: Dilute the silane coupling agent (KH560) with water, add polydimethylsiloxane (PDMS, CAS number: 9006‐65‐9; molecular formula: C 6 h 18 OSi 2 ), isobutanol and N,N-dimethylformamide, stirred for 2h and left to stand for later use.

[0044] Mix lithium silicate aqueous solution, potassium silicate aqueous solution and metered water in sequence, add the diluted wetting agent (TEGO245 and BYK346 mixed in equal amounts) and disodium EDTA, add the silane coupling agent (KH560) prepared above, Mixed solutio...

Embodiment 2

[0062] formula:

[0063] Table 6 Embodiment 2 formula

[0064]

[0065] Preparation process: Dilute the silane coupling agent (KH560) with water, add polydimethylsiloxane (PDMS, CAS number: 9006‐65‐9; molecular formula: C6H18OSi2) and dipropylene glycol methyl ether, stir for 2 hours and then set aside .

[0066] Mix lithium silicate aqueous solution, potassium silicate aqueous solution and metered water in sequence, add the diluted wetting agent (TEGO245 and BYK346 mixed in equal amounts) and disodium EDTA, add the silane coupling agent (KH560) prepared above, The mixed solution of polydimethylsiloxane (PDMS) and dipropylene glycol methyl ether was stirred at 50° C. for 1 hour, filtered and packaged for later use.

[0067] Coating properties: the appearance is slightly white, clear, the viscosity is about 10mPa.s, and the solid content is 29%;

[0068] Construction and drying: Mix the paint with sodium fluorosilicate aqueous solution and potassium tetraborate aqueous so...

Embodiment 3

[0073] formula:

[0074] Table 8 Example 3 formulation

[0075]

[0076]

[0077] Preparation process: Dilute the silane coupling agent (KH560) with water, add polydimethylsiloxane (PDMS, CAS number: 9006‐65‐9; molecular formula: C6H18OSi2) and propylene glycol butyl ether, stir for 2 hours and then set aside for later use.

[0078] Mix lithium silicate aqueous solution, potassium silicate aqueous solution and metered water in sequence, add the diluted wetting agent (TEGO245 and BYK346 mixed in equal amounts) and disodium EDTA, add the silane coupling agent (KH560) prepared above, The mixed solution of polydimethylsiloxane (PDMS) and propylene glycol butyl ether was stirred at 25°C for 4 hours, filtered and packaged for later use.

[0079] Coating performance: the appearance is clear and transparent, the viscosity is about 10mPa.s, and the solid content is 30%;

[0080] Construction and drying: Mix the paint with sodium fluorosilicate aqueous solution and potassium tet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com