Preparation device and method for high strength nanofiber bundle

A technology for nanofibers and preparation devices, which is applied in the fields of fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of poor mechanical properties, poor orientation and stretch, and poor fiber bundle state. The effect of strength enhancement and strength utilization improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

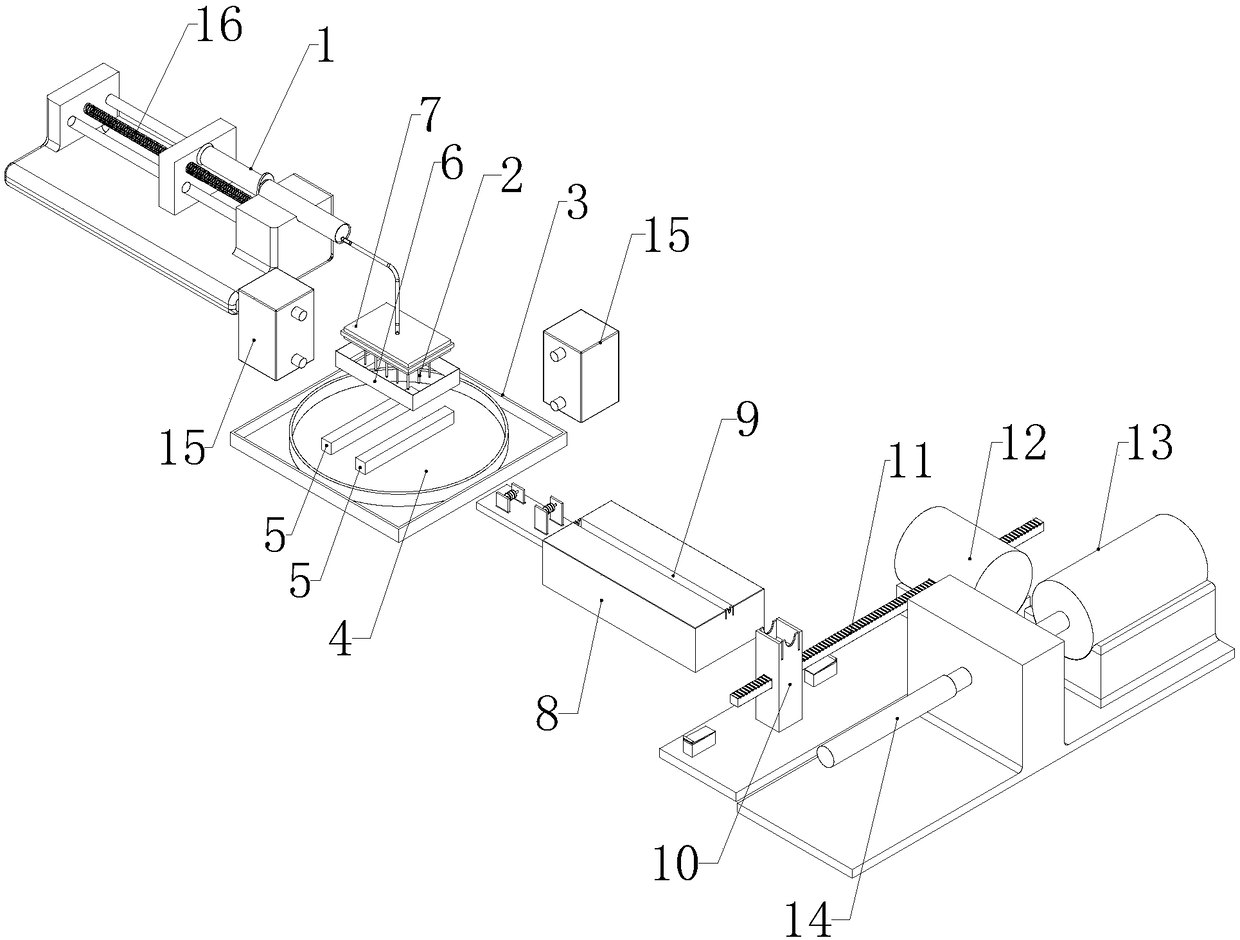

[0034] see figure 1 , the preparation device of the high-strength nanofiber bundle of a preferred embodiment of the present invention, comprises syringe 1, is located at the injector output end and is communicated with it nozzle 2, and the bottom of nozzle is also provided with water bath plate 3, and water bath plate includes for storage A liquid storage tank 4 and two electrode plates 5 arranged in parallel in the liquid storage tank.

[0035] Preferably, the number of spray heads is at least two.

[0036] Preferably, ring-shaped auxiliary electrodes 6 are provided on the outer sides of the plurality of shower heads.

[0037] Preferably, the device for preparing high-strength nanofiber bundles in this embodiment further includes a spinneret 7 on which the nozzles are arranged.

[0038] When in use, the operator introduces the bath liquid into the liquid storage tank, and then through electrospinning, the nanofibers are ejected from the nozzle and deposited in the bath liqu...

Embodiment 2

[0042] see figure 1 , the preparation device of the high-strength nanofiber bundle of the present embodiment comprises a syringe, a nozzle arranged at the output end of the syringe and communicated with it, and a water bath tray is also arranged under the nozzle head, and the water bath tray includes a liquid storage tank for storing liquid, a set Two electrode plates arranged in parallel in the reservoir. The output end of the water bath plate is provided with a guide roller whose conduction direction is perpendicular to the electrode plate.

[0043] Preferably, the device for preparing high-strength nanofiber bundles in this embodiment further includes a drying device, which includes a device body 8 and a drying tank 9 disposed on the surface of the device body.

[0044] Preferably, the preparation device of the high-strength nanofiber bundle in this embodiment also includes a traverse and arranging device, and the traverse and arranging device includes a traverse table 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com