Detoxifying agent of aflatoxins as well as preparation method and application of detoxifying agent

A kind of technology of aflatoxin and detoxification agent, which is applied in the direction of bacteria, application, food science, etc. used in food preparation, can solve the problems such as the influence of nutrient content, incomplete removal, and the removal efficiency is greatly affected by the environment. Achieve the effect of natural raw materials and mild degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Activation of the strain

[0036] Inoculate the Lactobacillus plantarum strains of the present invention on the activated medium for cultivation, the cultivation temperature is 37°C, and the time is 24h; the activated strains are inoculated in the fermenter, and the temperature is controlled at 37°C to 43°C, and the time is 24h to 36h , to prepare the fermentation broth.

[0037] The activation medium is: MRS medium, the composition is (g / L): peptone 10.0, meat extract 10.0, yeast extract powder 5.0, glucose 20.0, dipotassium hydrogen phosphate 2.0, diammonium hydrogen citrate 2.0, sodium acetate 5.0 , magnesium sulfate 0.58, manganese sulfate 0.28, cysteine 0.5, Tween 801.0, adjust pH 6.2-6.4.

[0038] The medium used for fermentation is: MRS medium, the composition of which is the same as above.

[0039] After the fermentation is completed, the bacterial content in the bacterial liquid is ≥10 8 cfu / mL.

[0040] The said Lactobacillus plantarum numbered BNCC 3364...

Embodiment 2

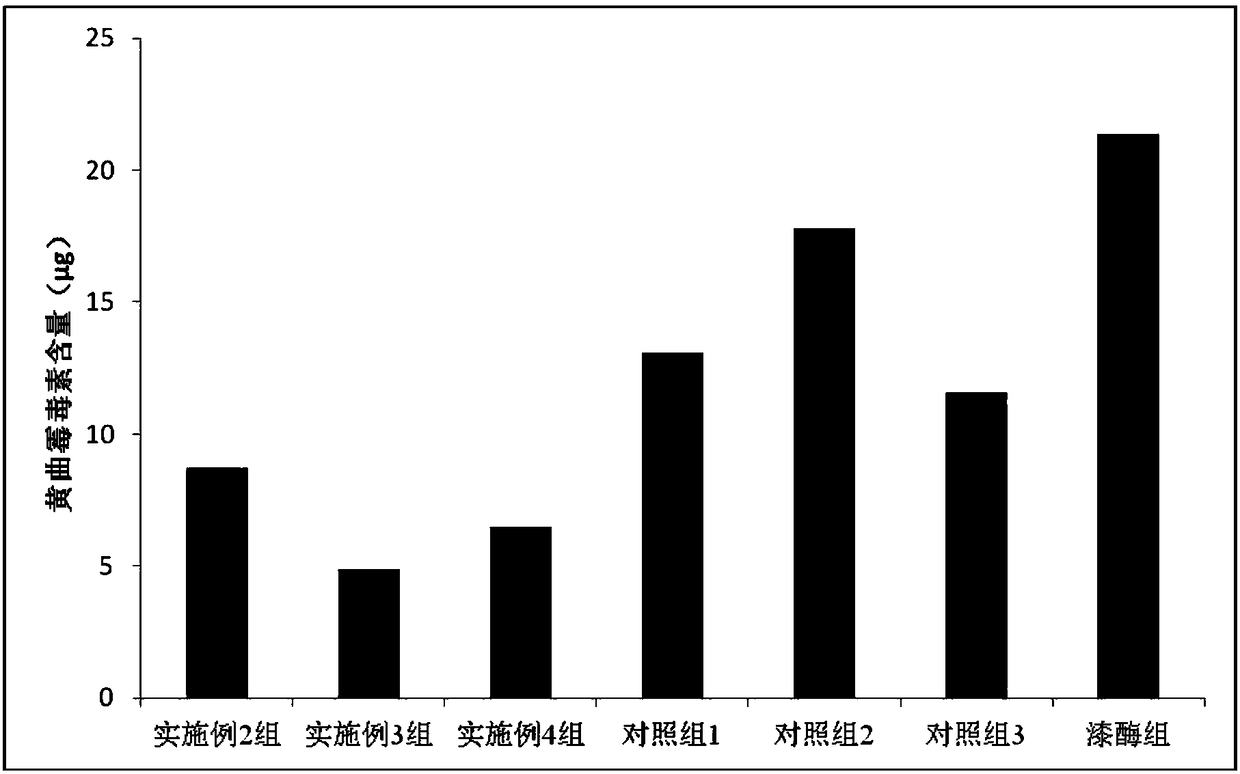

[0047] A detoxification agent for aflatoxin, which is prepared by asynchronously fermented plant components and laccase in a mass ratio of 97%:3%;

[0048] The specific preparation method is:

[0049] (1) Crush 10g of tangerine peel, 10g of litsea cubeba, 10g of scutellaria baicalensis, and 6g of myrtle to 40 mesh, add 8 times the weight of ultrapure water, stir well, steam sterilize at 100°C for 15min, and cool to room temperature;

[0050] (2) According to 10% inoculum amount, add Bacillus subtilis bacterium liquid to the material after cooling, 200rpm, 33 ℃, aerobic fermentation until the number of Bacillus subtilis ≥ 10 8 cfu / mL;

[0051] (3) Adding 1.5% sterile glucose by weight to the material after aerobic fermentation, adding Lactobacillus plantarum by 10% inoculation amount, and anaerobically fermenting until the number of Lactobacillus plantarum ≥ 10 8 cfu / mL;

[0052] (4) Add 3% laccase by weight to the above fermented liquid and mix evenly.

Embodiment 3

[0054] A detoxification agent for aflatoxin, which is prepared by asynchronously fermented plant components and laccase in a mass ratio of 98%: 2%;

[0055] The specific preparation method is:

[0056] (1) Grind 20g of tangerine peel, 20g of litsea cubeba, 15g of scutellaria baicalensis, and 8g of myrtle to 40 mesh, add 8 times the weight of ultrapure water, stir well, steam sterilize at 100°C for 15min, and cool to room temperature;

[0057] (2) According to 10% inoculum amount, add Bacillus subtilis bacterium liquid to the material after cooling, 200rpm, 33 ℃, aerobic fermentation until the number of Bacillus subtilis ≥ 10 8 cfu / mL;

[0058] (3) Adding 1.5% sterile glucose by weight to the material after aerobic fermentation, adding Lactobacillus plantarum by 10% inoculation amount, and anaerobically fermenting until the number of Lactobacillus plantarum ≥ 10 8 cfu / mL;

[0059](4) Add 2% laccase by weight to the above fermented liquid and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com