Method for synthesizing lapatinib intermediate in microchannel reactor

A technology of microchannel reactor and lapatinib, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of dechlorination degradation, poor purity, prone to violent explosion, etc., to achieve The effect of increasing yield, reducing energy consumption and saving economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

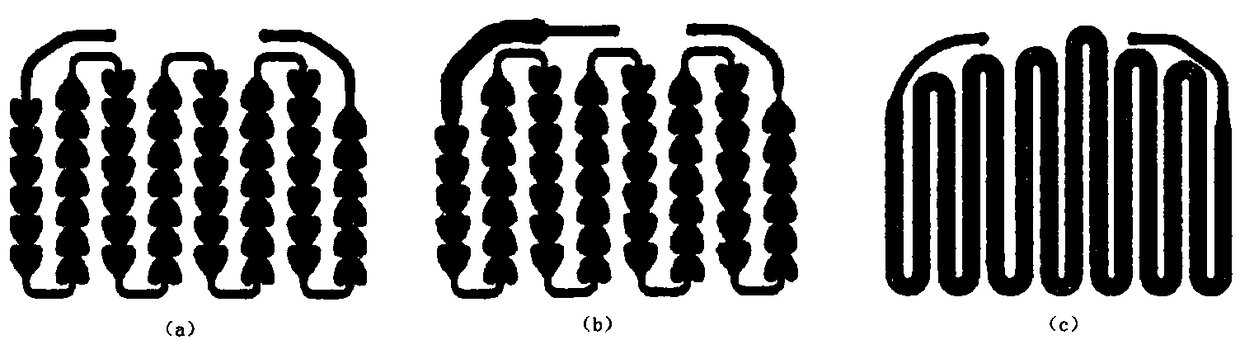

Method used

Image

Examples

Embodiment 1

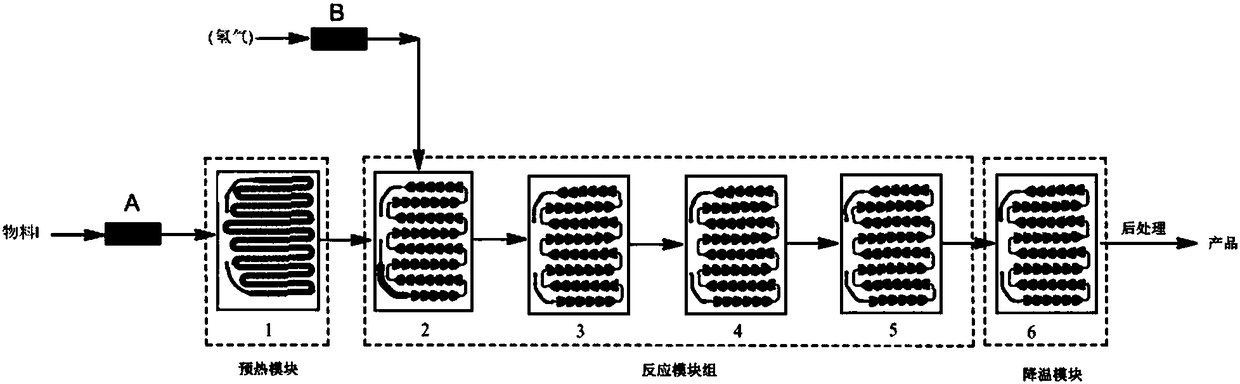

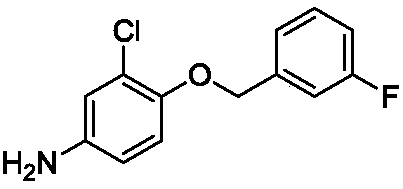

[0037] Embodiment 1. The method for the synthetic lapatinib intermediate of microchannel reactor.

[0038] (1) Weigh 200 g of raw material 3-chloro-4-(3-fluorobenzyloxy) nitrobenzene, then add 2 L of anhydrous methanol and 2 L of ethyl acetate, stir and dissolve and add 10 g of Pt content of 5% The Pt / C catalyst is fully stirred and mixed to form material I, and the flow rate of the slurry pump is adjusted so that the flow rate of material I is 50.0g / min, and it enters the microchannel reactor preheating module 1 for preheating.

[0039] (2) Regulating H 2 The flow velocity of gas flowmeter is 700ml / min, enters the reaction module 2 of microchannel reactor, reacts with the material I that enters reaction module 2, and described 3-chloro-4-(3-fluorobenzyloxy group) nitrobenzene The molar ratio with hydrogen is 1:3.2, the reaction temperature is 90°C, the temperature of the cooling module 6 is 20°C, the residence time of the reaction is 20s, and the reaction pressure is 1.5Mpa,...

Embodiment 2

[0040] Embodiment 2. The method for the synthetic lapatinib intermediate of microchannel reactor.

[0041] (1) Weigh 200 g of raw material 3-chloro-4-(3-fluorobenzyloxy) nitrobenzene, then add 2 L of absolute ethanol and 2 L of ethyl acetate, stir and dissolve and add 6 g of Pd content of 10% The Pd / C catalyst is fully stirred and mixed to form material I, and the flow rate of the slurry pump is adjusted so that the flow rate of material I is 40.0g / min, and it enters the microchannel reactor preheating module 1 for preheating.

[0042] (2) Regulating H 2 The flow velocity of gas flowmeter is 550ml / min, enters the reaction module 2 of microchannel reactor, reacts with the material I that enters reaction module 2, and described 3-chloro-4-(3-fluorobenzyloxy group) nitrobenzene The molar ratio with hydrogen is 1:3.2, the reaction temperature is 70°C, the temperature of the cooling module 6 is 20°C, the residence time of the reaction is 30s, and the reaction pressure is 1.2Mpa, c...

Embodiment 3

[0043] Embodiment 3. the method for microchannel reactor synthetic lapatinib intermediate.

[0044] (1) Weigh 250 g of raw material 3-chloro-4-(3-fluorobenzyloxy) nitrobenzene, then add 2.5 L of anhydrous methanol and 2 L of tetrahydrofuran, stir and dissolve and add 15 g of Pt with a Pt content of 8%. The / C catalyst is fully stirred and mixed to form material I, and the flow rate of the slurry pump is adjusted so that the flow rate of material I is 30.0g / min, and it enters the microchannel reactor preheating module 1 for preheating.

[0045] (2) Regulating H 2 The flow velocity of gas flowmeter is 400ml / min, enters the reaction module 2 of microchannel reactor, reacts with the material I that enters reaction module 2, and described 3-chloro-4-(3-fluorobenzyloxy group) nitrobenzene The molar ratio with hydrogen is 1:3.0, the reaction temperature is 100°C, the temperature of the cooling module 6 is 25°C, the residence time of the reaction is 40s, and the reaction pressure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com