Method for preparing single-component polyurethane coating from coupling agent modified fly ash

A polyurethane coating and fly ash technology, applied in the field of polyurethane coatings, to achieve the effects of improving elongation at break, reducing production costs, and reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

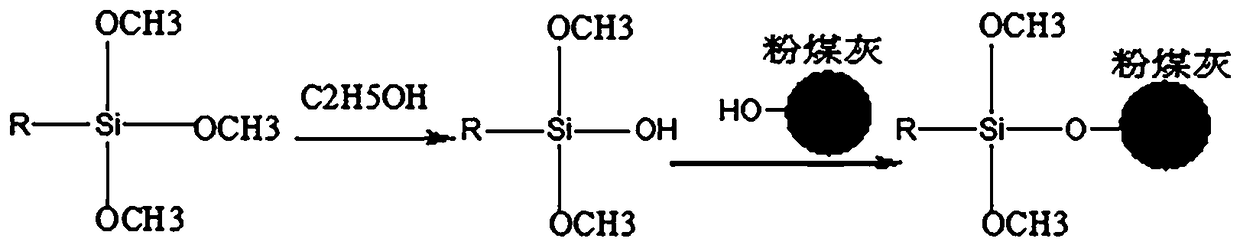

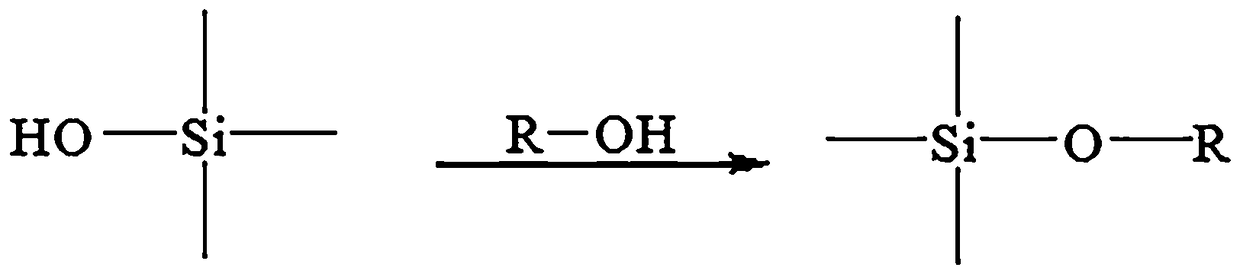

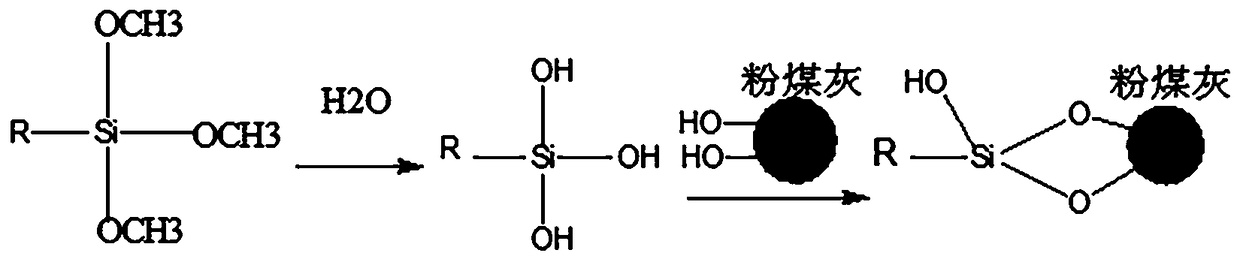

[0023] A kind of coupling agent modified fly ash prepares the method for one-component polyurethane coating, comprises the steps:

[0024] (1) Preparation of silane coupling agent solution: Take 60-90mL of water-ethanol solution with a mass concentration of 75-95%, add 2-4g of silane coupling agent, and reflux at 75-95°C for 1.5-2.5h, And use hydrochloric acid to adjust the pH value of the solution to 3.5-4.5, after the reflux is completed, naturally cool to room temperature to obtain a silane coupling agent solution;

[0025] (2) Preparation of modified fly ash: Take 38-42mL of the silane coupling agent solution, add 0.3-0.4g of fly ash, reflux at a constant temperature of 98-102°C for 50-70min, add an appropriate amount of NaOH to adjust the pH to neutral, dry at 75-85°C, and grind into powder to obtain modified fly ash;

[0026] (3) Preparation of one-component polyurethane: Add 14-18 g of Mn=2000 polyol POL-356 and 3-5 g of Mn=600 polyol POL-3195 into 25-35 mL of ethyl ac...

Embodiment 2

[0030] A kind of coupling agent modified fly ash prepares the method for one-component polyurethane coating, comprises the steps:

[0031] (1) Preparation of silane coupling agent solution: Take 75mL of water-ethanol solution with a mass concentration of 85%, add 3.000g of silane coupling agent, reflux at 85°C for 2h, and adjust the pH value of the solution to 4 with hydrochloric acid, After reflux finishes, cool down to room temperature naturally to obtain a silane coupling agent solution;

[0032] (2) Preparation of modified fly ash: Take 40mL of the silane coupling agent solution, add 0.3500g of fly ash, reflux at a constant temperature of 100°C for 60min, add an appropriate amount of NaOH to adjust the pH to neutral, at 80°C Dry and grind into powder to obtain modified fly ash;

[0033] (3) Preparation of one-component polyurethane: Add 16g of Mn=2000 polyol POL-356 and 4g of Mn=600 polyol POL-3195 into 30mL of ethyl acetate solution, reflux and stir in a constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com