Industrial Saccharomyces cerevisiae strain for high-yield production of xylitol and ethanol by co-fermenting xylose and glucose and construction method

A technology of Saccharomyces cerevisiae strain and construction method, which is applied in the field of industrial Saccharomyces cerevisiae strains and its construction, which can solve the problems of unsatisfactory fermentation requirements, slow xylose metabolism rate, complex expression system, etc., achieve superior performance and increase xylose consumption rate , The effect of ethanol production increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

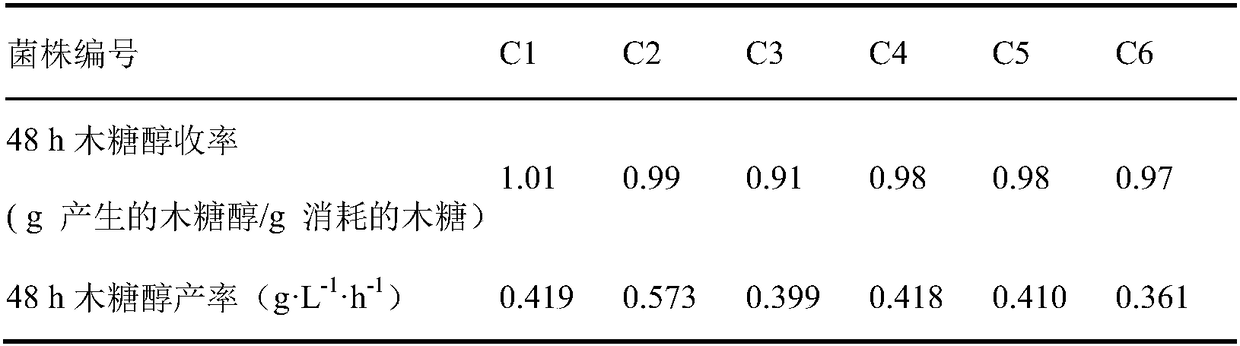

Examples

Embodiment 1

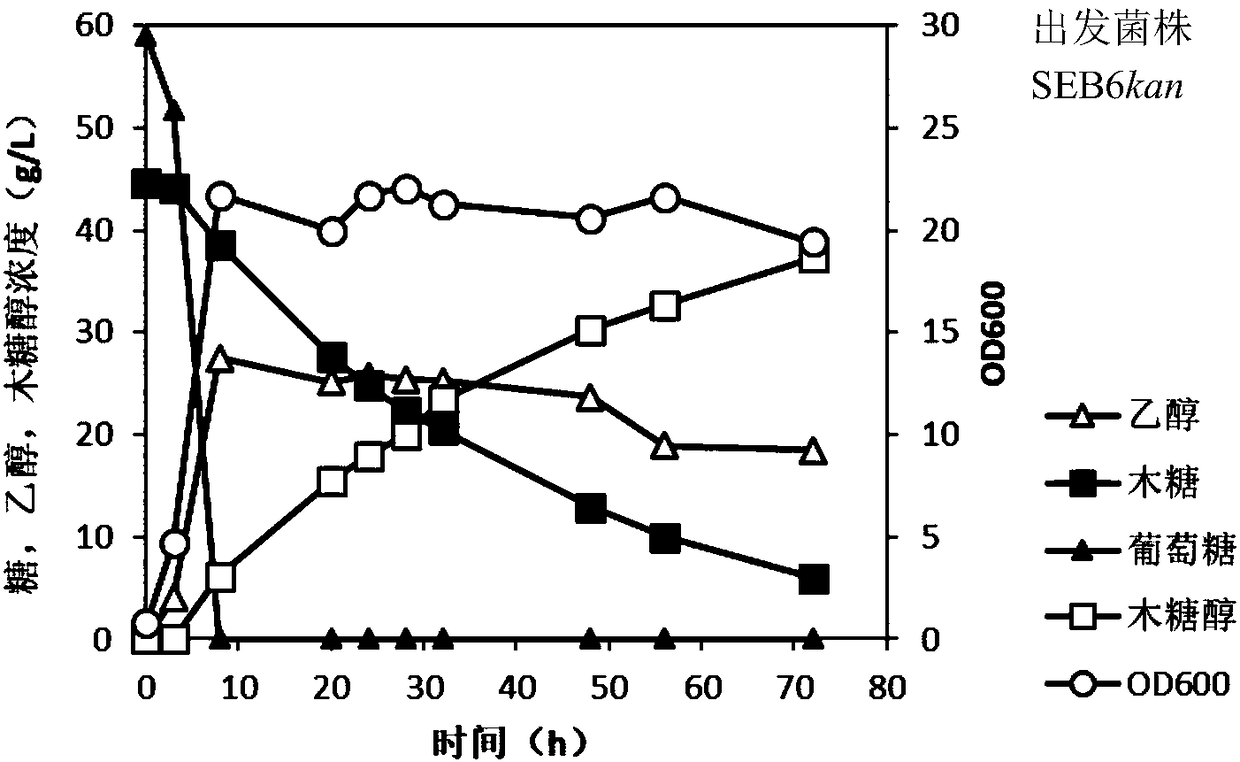

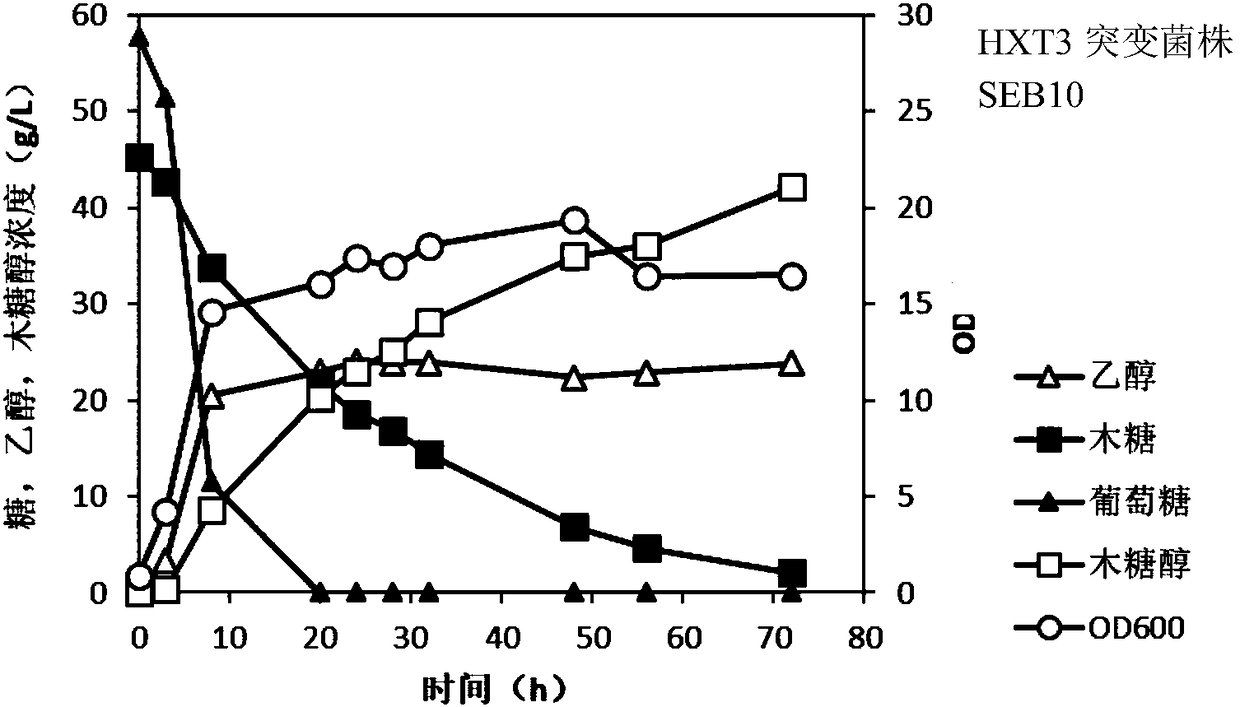

[0055] The present embodiment is the construction method of Saccharomyces cerevisiae strain SEB10, and it comprises the following steps:

[0056] (1) Knock out the screening marker KanMX gene: Transform the inducible plasmid pSH47 / ZEO (1 μg) containing Cre enzyme yeast expression into the starting Saccharomyces cerevisiae strain SEB6 by the lithium acetate transformation method, at pH 7 .2 In the 2% YPD flat plate, screen the positive transformants with intact bacterial colonies. Plasmid pSH47 / ZEO is an existing plasmid, and the method of knocking out the KanMX gene of the screening marker G418 is disclosed in a document reported by Tomitaka et al. in 2013. The title of the document is: Isolation and identification of a mutated and recombined strain Saccharomyces cerevisiae utilizing xylose; Authors: Tomitaka M, Taguchi H, Fukuda K, Akamatsu T, Kida K; Publication: Journal of Biological Science and Bioengineering. 2013, 116(6): 706-715. The above-mentioned homologous recombin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com