Tungsten oxide-polypyrrole core-shell heterostructure nanowires and preparation method thereof

A technology of tungsten oxide nanowires and polypyrrole core-shell, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of unstable performance of core-shell materials, and achieve the effect of easy control of process parameters, convenient operation, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

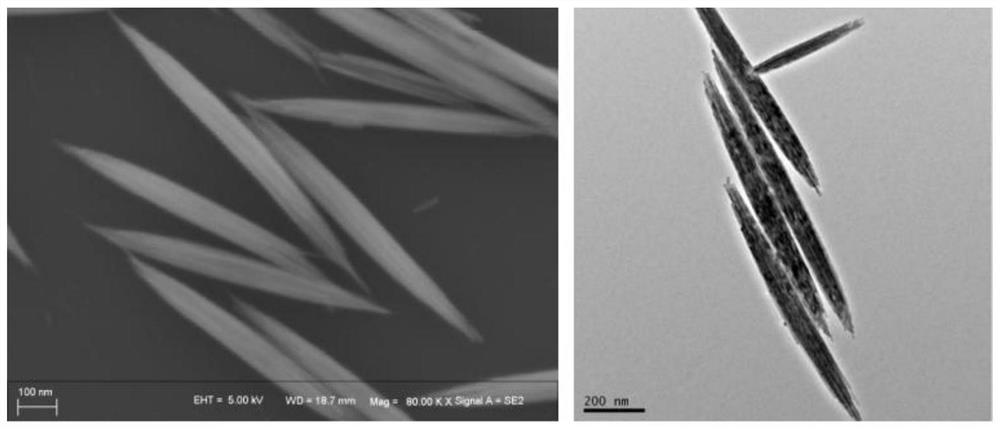

Embodiment 1

[0029] (1) Preparation of tungsten oxide nanowires by solvothermal method

[0030] The tungsten hexachloride powder was added to 60 ml of cyclohexanol, and magnetically stirred for 20 minutes to completely dissolve the tungsten hexachloride powder to obtain a uniform solution with a tungsten hexachloride concentration of 0.005 mol / L. The cyclohexanol solution of the tungsten hexachloride was transferred into a high-pressure reaction kettle lined with polytetrafluoroethylene, and after sealing, the reaction kettle was placed in an oven for heating to carry out solvothermal reaction, and the oven working temperature was 200 ° C, and the heating time for 6h.

[0031] (2) Cleaning of tungsten oxide nanowires

[0032] After the solvothermal reaction was completed, the autoclave was naturally cooled to room temperature, the reaction kettle was taken out, and the blue solid-liquid reactant in the reaction kettle was centrifuged, and the rotation speed of the centrifuge was set to 50...

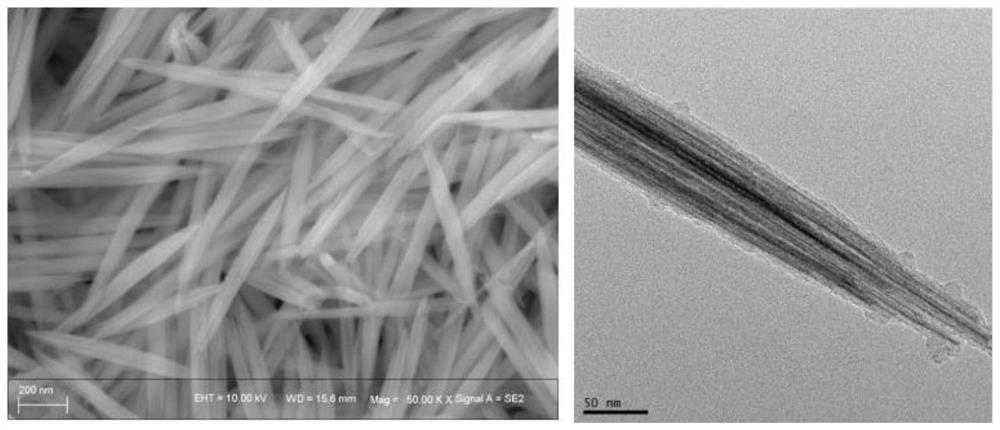

Embodiment 2

[0039] (1) Preparation of tungsten oxide nanowires by solvothermal method

[0040] The tungsten hexachloride powder was added to 60 ml of cyclohexanol, and the tungsten hexachloride powder was completely dissolved by magnetic stirring for 10 minutes to obtain a uniform solution with a tungsten hexachloride concentration of 0.005 mol / L. The cyclohexanol solution of the tungsten hexachloride was transferred to an autoclave lined with polytetrafluoroethylene. After sealing, the reactor was placed in an oven for heating to carry out solvothermal reaction. The oven working temperature was 180° C., and the heating time is 9h.

[0041] (2) Cleaning of tungsten oxide nanowires

[0042] After the solvothermal reaction was completed, the autoclave was naturally cooled to room temperature, the reaction kettle was taken out, and the blue solid-liquid reactant in the reaction kettle was centrifuged, and the rotation speed of the centrifuge was set to 4000 r / min. The solid obtained by cen...

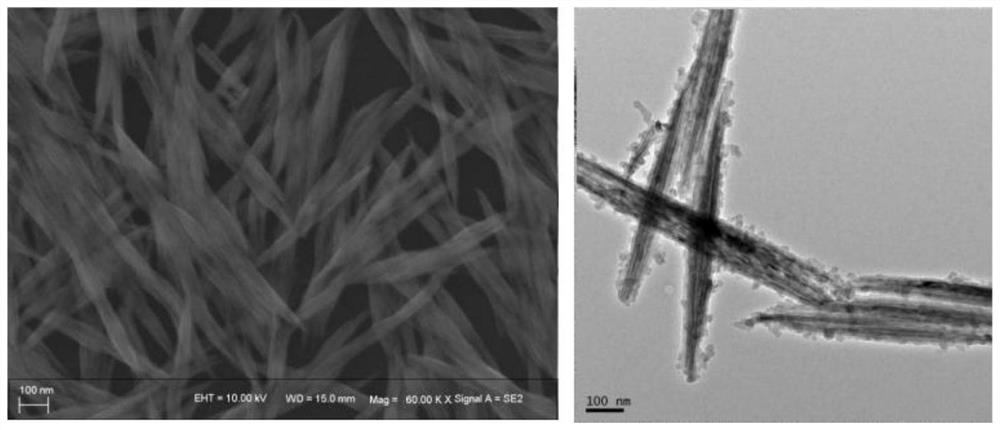

Embodiment 3

[0050] (1) Preparation of tungsten oxide nanowires by solvothermal method

[0051] The tungsten hexachloride powder was added to 60 ml of cyclohexanol, and magnetically stirred for 40 minutes to completely dissolve the tungsten hexachloride powder to obtain a uniform solution with a tungsten hexachloride concentration of 0.005 mol / L. The cyclohexanol solution of tungsten hexachloride was transferred to an autoclave lined with polytetrafluoroethylene. After sealing, the autoclave was heated in an oven for solvothermal reaction. The oven working temperature was 220°C, and the heating time for 7h.

[0052] (2) Cleaning of tungsten oxide nanowires

[0053] After the solvothermal reaction was completed, the autoclave was naturally cooled to room temperature, the reaction kettle was taken out, and the blue solid-liquid reactant in the reaction kettle was centrifuged, and the rotation speed of the centrifuge was set to 6000 r / min. The solid obtained by centrifugation was washed twi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com