Wet wipe with polyhexamethylene guanidine/biguanide hydrochloride immersion fluid and preparation method of immersion fluid

A technology of polyhexamethylene guanidine and biguanide hydrochloride, which is used in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc. Soft texture, good degradability, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

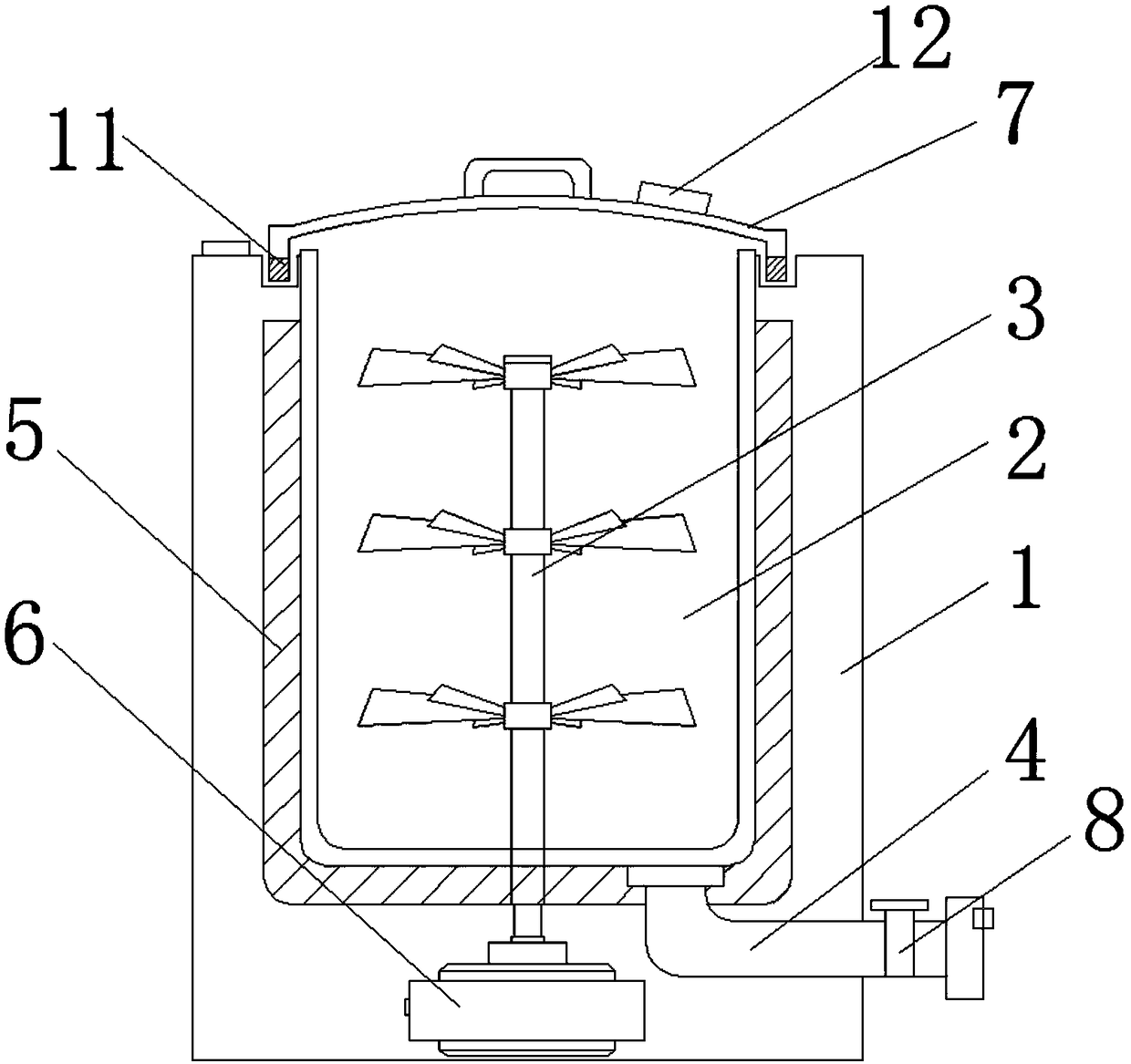

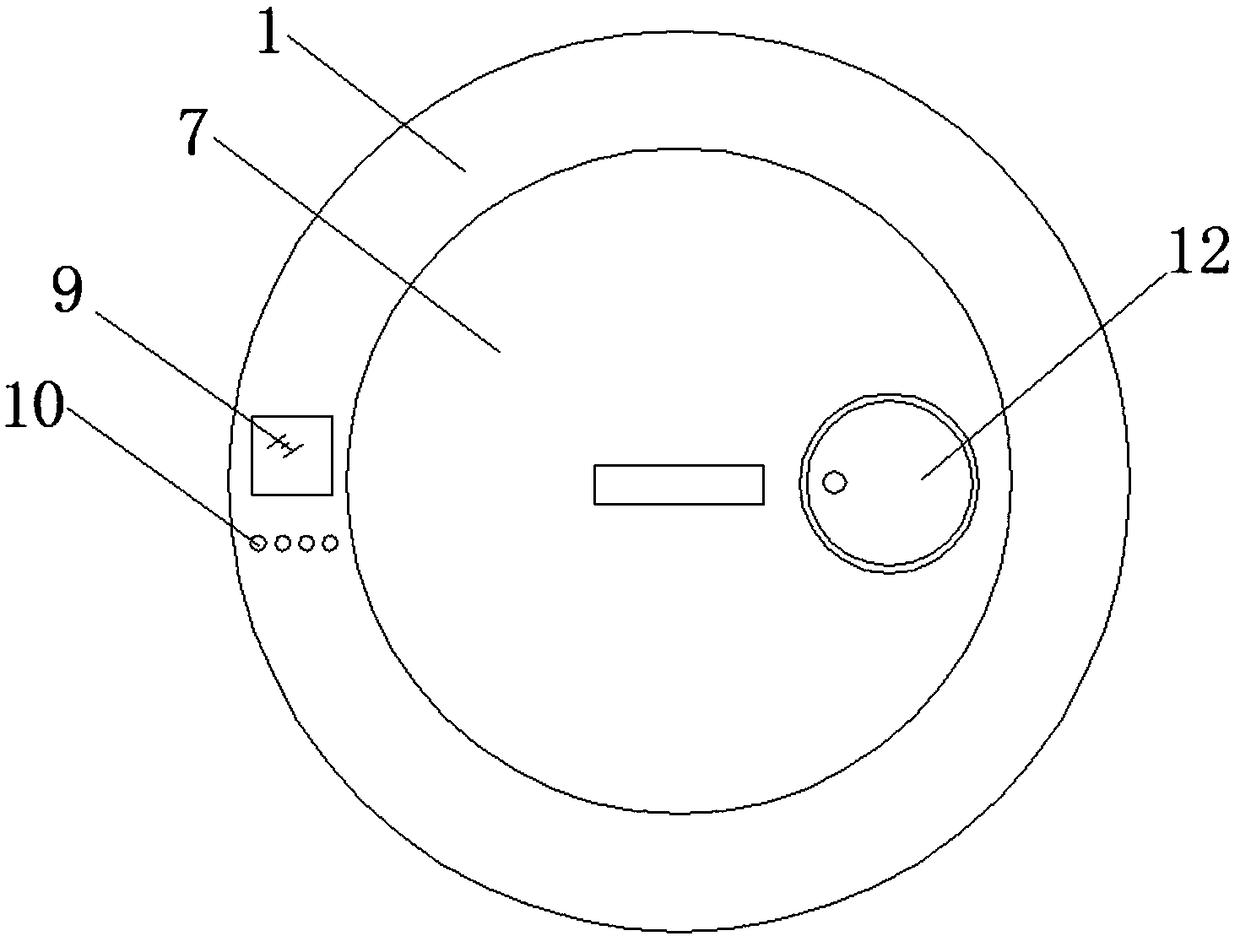

Image

Examples

Embodiment 1

[0037] A kind of polyhexamethylene guanidine / biguanide hydrochloride soaking liquid, contains following mass ratio composition: 5 parts of vitamins, 20 parts of additives, 25 parts of olive oil, 20 parts of humectants, 15 parts of emulsifiers, 2 parts of polyhexamethyleneguanidine / biguanide hydrochloride and 150 parts of purified water.

[0038] In this embodiment: the vitamins include 5 parts of vitamin E, 5 parts of vitamin B5 and 5 parts of vitamin C.

[0039] In this embodiment: the additives include 90 parts of preservatives and 10 parts of essence.

[0040] In this embodiment: the preservative is one or more mixtures of benzoic acid, sodium diacetate and sorbic acid.

[0041] In this embodiment: the humectant is a mixture of one or more of propylene glycol, sorbitol, glycerin, polyethylene glycol 200, polyethylene glycol 400, butylene glycol and betaine.

[0042] A preparation method of polyhexamethyleneguanidine / biguanide hydrochloride dipping solution, comprising the...

Embodiment 2

[0053] A kind of polyhexamethylene guanidine / biguanide hydrochloride soaking liquid, contains following mass ratio composition: 8 parts of vitamins, 28 parts of additives, 35 parts of olive oil, 25 parts of humectants, 20 parts of emulsifiers, 3 parts of polyhexamethyleneguanidine / biguanide hydrochloride and 200 parts of purified water.

[0054] In this embodiment: the vitamins include 5 parts of vitamin E, 5 parts of vitamin B5 and 5 parts of vitamin C.

[0055] In this embodiment: the additives include 90 parts of preservatives and 10 parts of essence.

[0056] In this embodiment: the preservative is one or more mixtures of benzoic acid, sodium diacetate and sorbic acid.

[0057] In this embodiment: the humectant is a mixture of one or more of propylene glycol, sorbitol, glycerin, polyethylene glycol 200, polyethylene glycol 400, butylene glycol and betaine.

[0058] A preparation method of polyhexamethyleneguanidine / biguanide hydrochloride dipping solution, comprising the...

Embodiment 3

[0069] A kind of polyhexamethylene guanidine / biguanide hydrochloride soaking liquid, contains following mass ratio composition: 10 parts of vitamins, 35 parts of additives, 50 parts of olive oil, 30 parts of humectants, 25 parts of emulsifiers, 5 parts of polyhexamethyleneguanidine / biguanide hydrochloride and 250 parts of purified water.

[0070] In this embodiment: the vitamins include 5 parts of vitamin E, 5 parts of vitamin B5 and 5 parts of vitamin C.

[0071] In this embodiment: the additives include 90 parts of preservatives and 10 parts of essence.

[0072] In this embodiment: the preservative is one or more mixtures of benzoic acid, sodium diacetate and sorbic acid.

[0073] In this embodiment: the humectant is a mixture of one or more of propylene glycol, sorbitol, glycerin, polyethylene glycol 200, polyethylene glycol 400, butylene glycol and betaine.

[0074] A preparation method of polyhexamethyleneguanidine / biguanide hydrochloride dipping solution, comprising th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com