Electrode coating, electrode with low crack sensitivity and preparation and application thereof

A welding rod coating and low-crack technology, applied in the field of welding rods and welding rod coatings, can solve problems such as arc instability, high sensitivity to thermal cracks, and increased spatter, and achieve the effect of improving crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

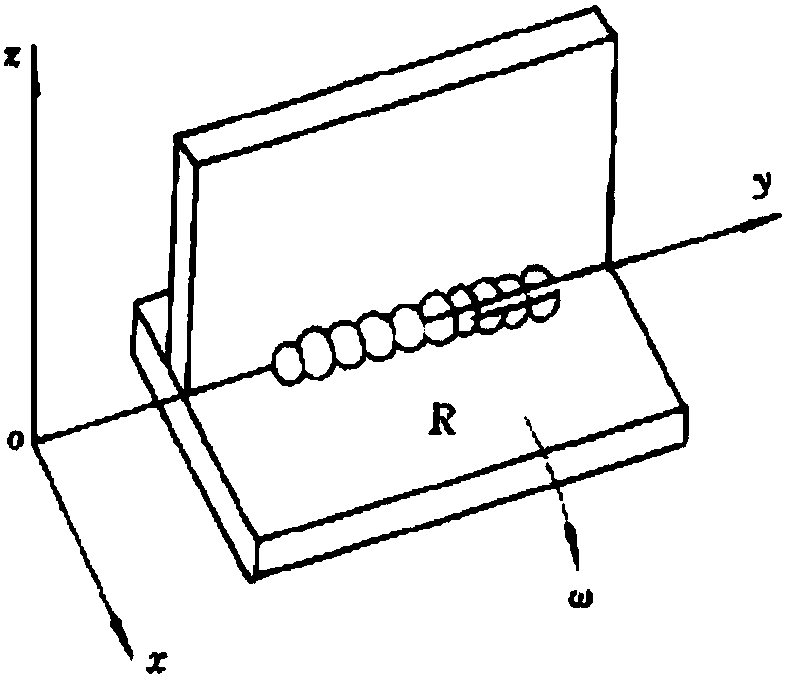

Image

Examples

Embodiment 1

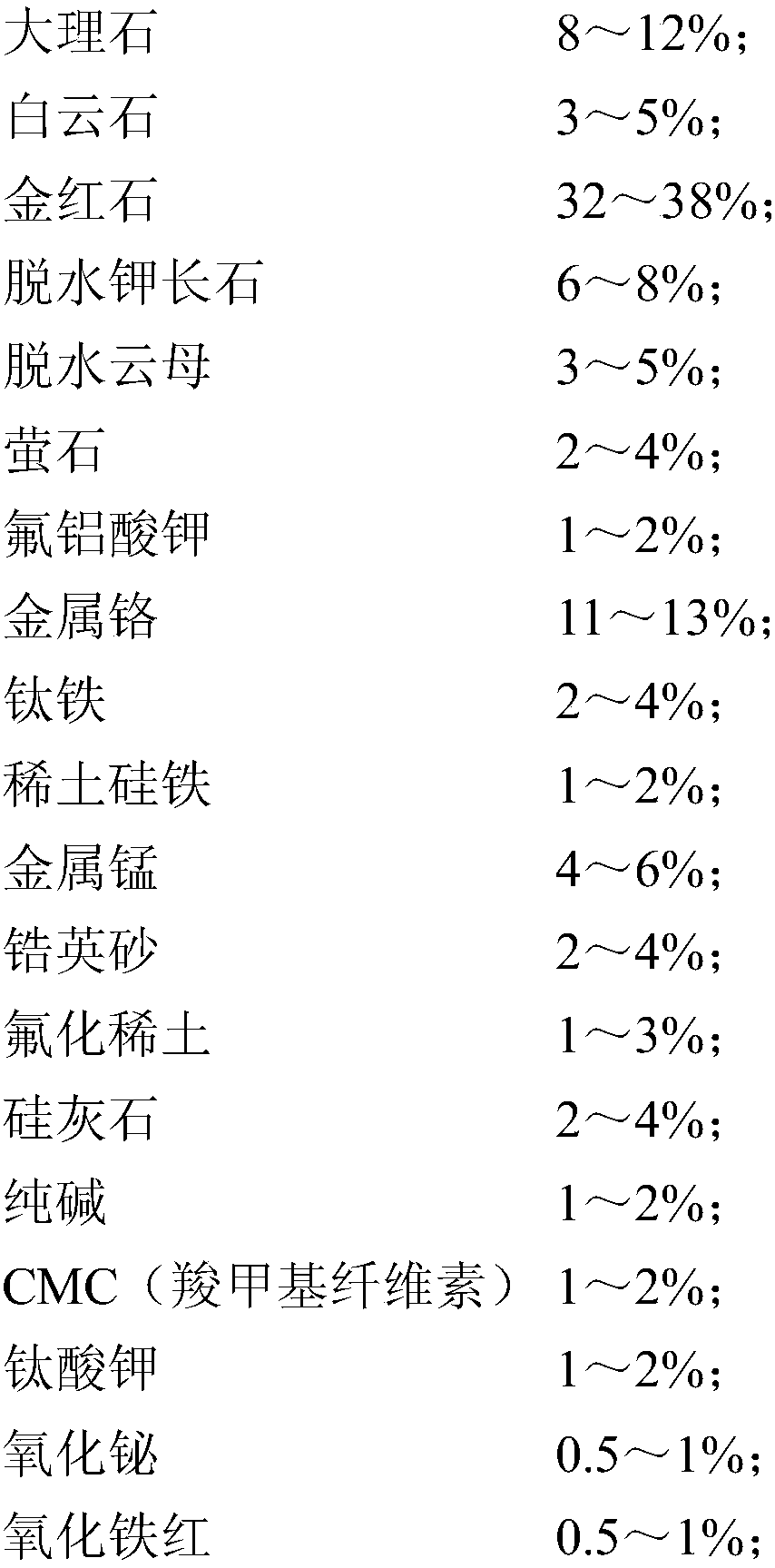

[0081] A welding rod coating, comprising the following components by mass percentage:

[0082]

[0083] A method for preparing an electrode with low crack sensitivity, comprising the steps of:

[0084] (1) Mix and stir the components of the above-mentioned electrode coating according to the proportion, then add the mixed water glass of the above-mentioned electrode coating with a total weight of 18wt%, a modulus of 2.3 to 2.6, and potassium: sodium = 1:1 for stirring , and mix evenly to obtain electrode coating;

[0085] (2) Pressure-coat the electrode coating and welding core (H03Cr19Ni12No2 welding wire) prepared in step (1) on a hydraulic electrode press coating machine to obtain an electrode with low crack sensitivity, wherein the electrode coating accounts for the total Heavy 42wt%.

Embodiment 2

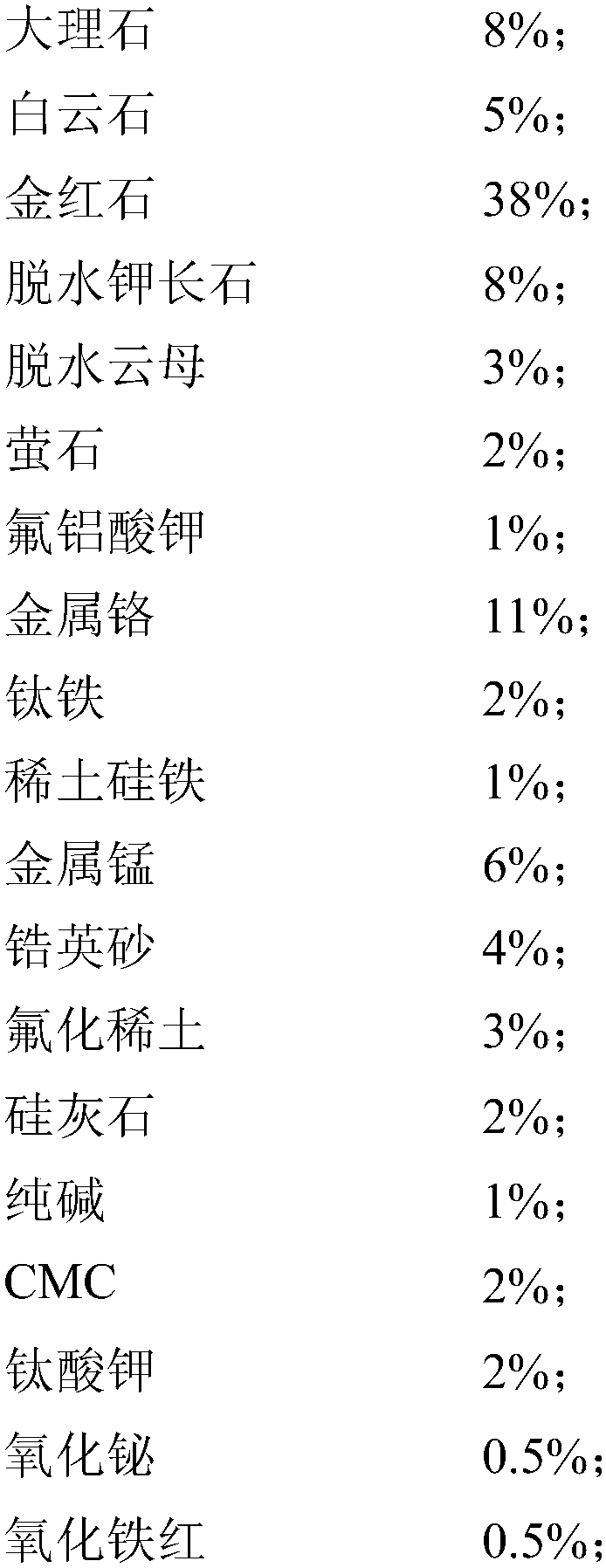

[0087] A welding rod coating, comprising the following components by mass percentage:

[0088]

[0089] A method for preparing an electrode with low crack sensitivity, comprising the steps of:

[0090] (1) Mix and stir the components of the above-mentioned electrode coating according to the ratio, and then add the mixed water glass of the above-mentioned electrode coating with a total weight of 18.5wt%, a modulus of 2.3 to 2.6, and potassium: sodium = 1:1. Stir and mix evenly to obtain electrode coating;

[0091] (2) Pressure-coat the electrode coating and welding core (H03Cr19Ni12No2 welding wire) prepared in step (1) on a hydraulic electrode press coating machine to obtain an electrode with low crack sensitivity, wherein the electrode coating accounts for the total 40% by weight.

Embodiment 3

[0093] A welding rod coating, comprising the following components by mass percentage:

[0094]

[0095] A method for preparing an electrode with low crack sensitivity, comprising the steps of:

[0096] (1) Mix and stir the components of the above-mentioned electrode coating according to the proportioning ratio, then add the components of the above-mentioned electrode coating with a total weight of 19wt%, a modulus of 2.3 to 2.6, potassium:sodium=1:1 mixed water glass, and stir. Mix evenly to obtain electrode coating;

[0097] (2) Pressure-coat the electrode coating and welding core (H03Cr19Ni12No2 welding wire) prepared in step (1) on a hydraulic electrode press coating machine to obtain an electrode with low crack sensitivity, wherein the electrode coating accounts for the total 45% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com