Solid-phase synthesizing method of polypeptide, synthesized magnetic nanometer probe and application thereof

A solid-phase synthesis and magnetic technology, applied in the preparation method of peptides, magnetic materials, magnetic objects, etc., can solve the problems of difficult to obtain peptides, and achieve the effect of easy separation and extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

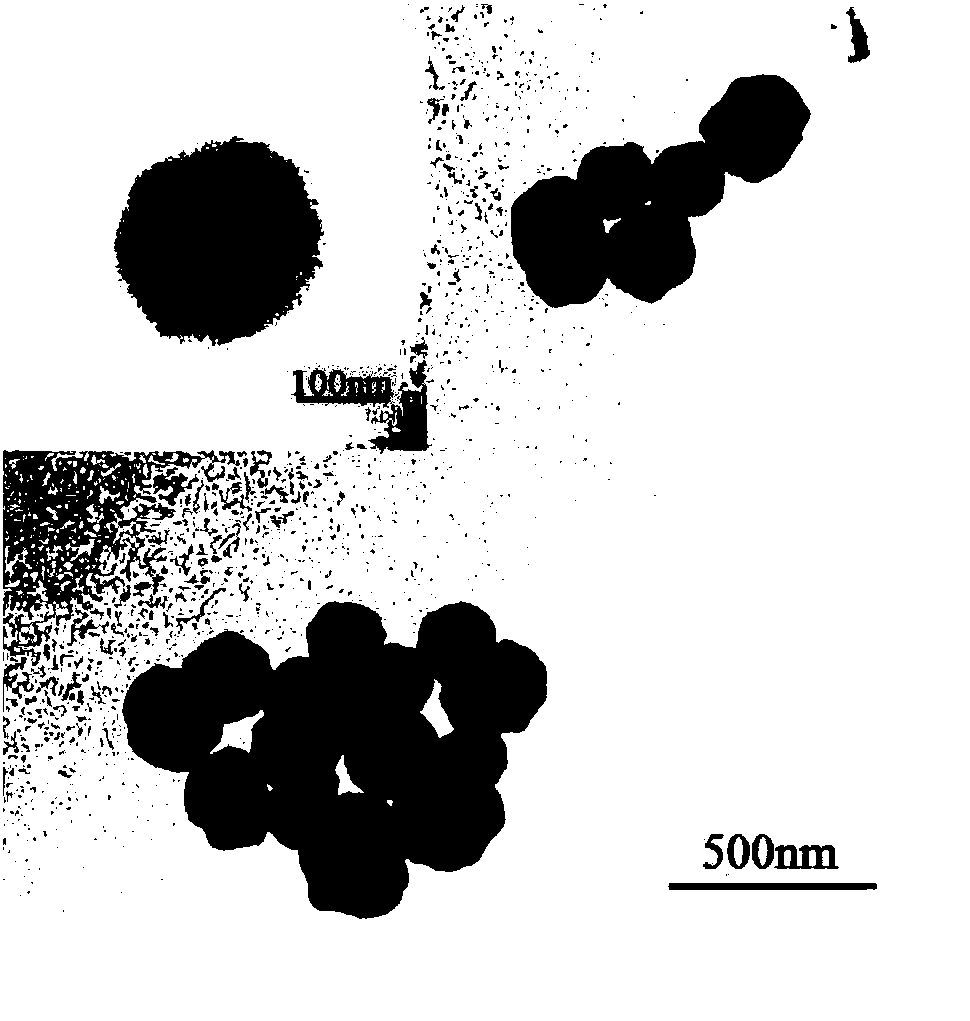

[0043] 0.1g superparamagnetic Fe 3 O 4 Nanoparticles were dispersed in 100ml of absolute ethanol, added 1.0ml of ammonia, mixed well, then added 200μLTEOS, placed in an ultrasonic machine with a power of 100w, sonicated for 6h, and added 200μLTEOS every 2h for a total of 2 times. After the reaction, The product is magnetically separated and washed with deionized water and absolute ethanol alternately 3 times to obtain Fe 3 O 4 @SiO 2 Nanoparticle

[0044] Take 0.05g of Fe obtained 3 O 4 @SiO 2 Nanoparticles were dispersed in a mixed solution of 30ml absolute ethanol and 30ml deionized water, added 0.075g CTAB, placed in an ultrasonic machine with a power of 100W and sonicated for 2h, added 0.048g resorcinol, 75μLTEOS, stirred for 10min and then added 183μL Formaldehyde solution, 230μL ammonia water, stirred at room temperature for 24h, centrifuged the product, washed with ethanol 3 times to obtain the required Fe 3 O 4 @SiO 2 @PF Three-layer core-shell structured nanoparticles.

[...

Embodiment 2

[0053] 0.1g superparamagnetic Fe 3 O 4 Nanoparticles were dispersed in 100ml of absolute ethanol, added 1.0ml of ammonia, mixed well, then added 200μLTEOS, placed in an ultrasonic machine with a power of 100w, sonicated for 6h, and added 200μLTEOS every 2h for a total of 2 times. After the reaction, The product is magnetically separated and washed with deionized water and absolute ethanol alternately 3 times to obtain Fe 3 O 4 @SiO 2 Nanoparticle

[0054] Take 0.05g of Fe obtained 3 O 4 @SiO 2 Nanoparticles were dispersed in a mixed solution of 30ml absolute ethanol and 30ml deionized water, added 0.075g CTAB, placed in an ultrasonic machine with a power of 100W and sonicated for 2h, added 0.1g resorcinol, 75μLTEOS, stirred for 10min and then added 366μL Formaldehyde solution, 230μL ammonia water, stirred at room temperature for 24h, centrifuged the product, washed with ethanol 3 times to obtain the required Fe 3 O 4 @SiO 2 @PF Three-layer core-shell structured nanoparticles.

[00...

Embodiment 3

[0062] 0.1g superparamagnetic Fe 3 O 4 Nanoparticles are dispersed in 100ml of absolute ethanol, add 1.0ml of ammonia water, mix well, then add 200μL of TEOS, place in a 100w ultrasonic machine, sonicate for 6h, add 200μL of TEOS every 2h, add 2 times, the reaction is over After that, the product was magnetically separated and washed with deionized water and absolute ethanol alternately 3 times to obtain Fe 3 O 4 @SiO 2 Nanoparticle

[0063] Take 0.05g of Fe obtained 3 O 4 @SiO 2 Nanoparticles were dispersed in a mixed solution of 30ml absolute ethanol and 30ml deionized water, added 0.075g CTAB, placed in an ultrasonic machine with a power of 100W and sonicated for 2h, added 0.048g resorcinol, 75μLTEOS, stirred for 10min and then added 183μL Formaldehyde solution, 230μL ammonia water, stirred at room temperature for 24h, centrifuged the product, washed with ethanol 3 times to obtain the required Fe 3 O 4 @SiO 2 @PF Three-layer core-shell structured nanoparticles.

[0064] Take 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap