Low-temperature kitchen heavy grease dirt cleaning agent and preparation method thereof

A cleaning agent and heavy oil pollution technology, applied in the field of cleaning agents, can solve the problems of corrosion, danger, and inhalation of the surface of the appliance, and achieve super penetration and degreasing ability, non-corrosive stability, and good tolerance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

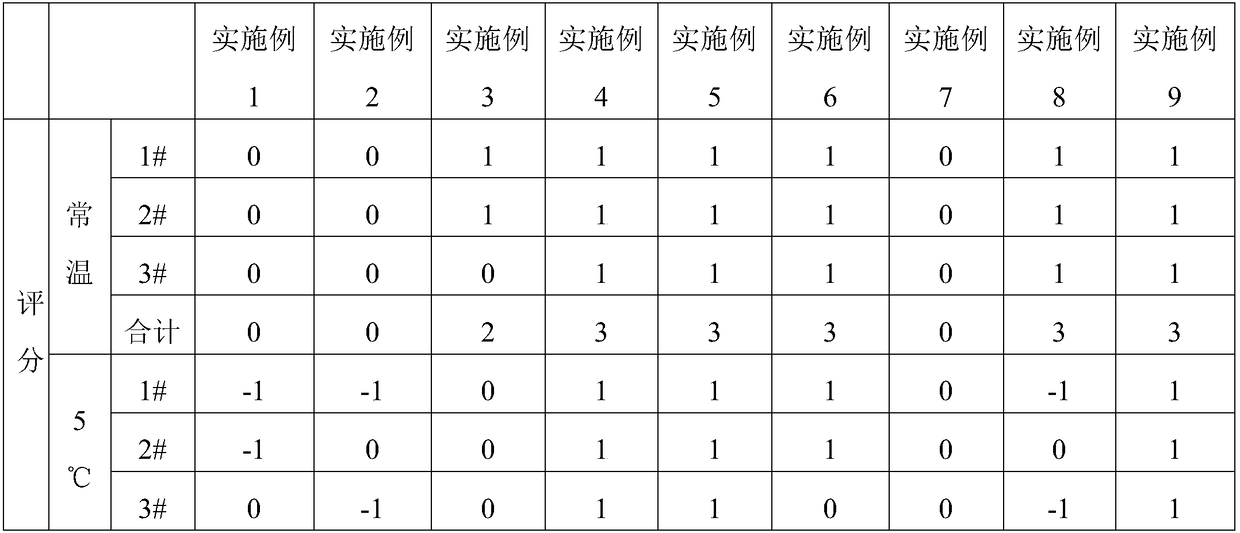

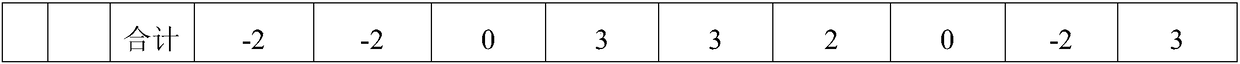

[0032] The present invention will be described in further detail below in conjunction with specific examples.

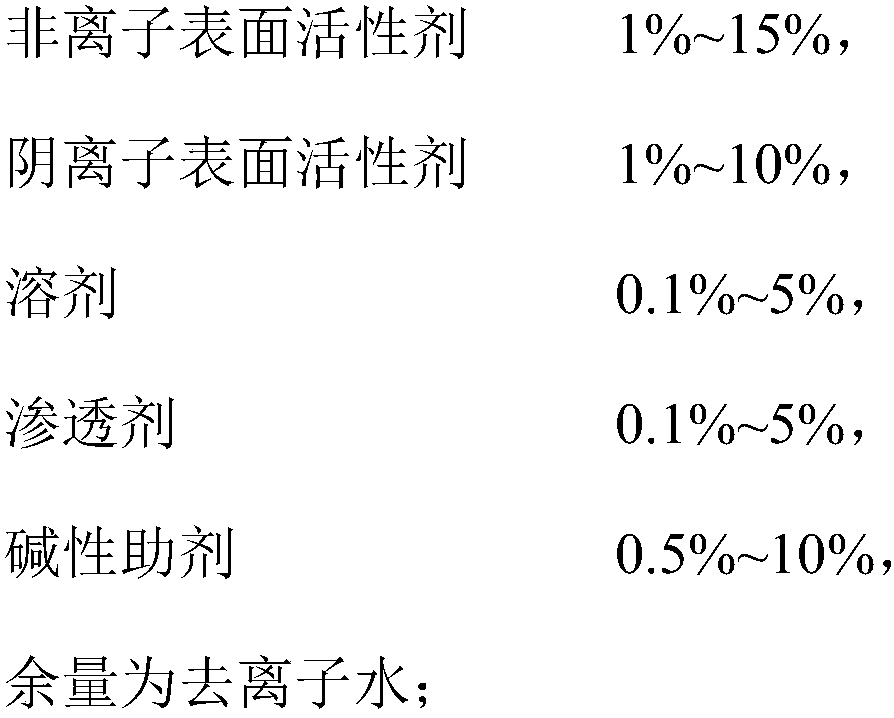

[0033] The components and mass percentages of the low-temperature cleaning agent for heavy oil stains in the kitchen described in Examples 1 to 9 are shown in Table 1.

[0034] Table 1 Embodiment 1~9 each component and its mass percent

[0035] Example

1

2

3

4

5

6

7

8

9

Fatty acid methyl ester ethoxylate / %

1

1

1

8

8

8

15

15

15

Fatty acid methyl ester polyoxyethylene ether sulfonate / %

1

5

10

1

5

10

1

5

10

Propylene glycol butyl ether / %

0.1

2

5

2

0.1

5

0.1

5

2

Fatty alcohol polyoxyethylene ether (JFC) / %

0.1

2

5

5

2

0.1

2

0.1

5

0.68

3.4

6.8

6.8

3.4

0.68

0.68

6.8

3.4

Anhydrous sodium carbonate / %

0.32

1.6

3.2

3.2

1.6

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com