Method for synthesizing high-activity Ni-Mo-Co hydrogen evolution catalyst under acid environment

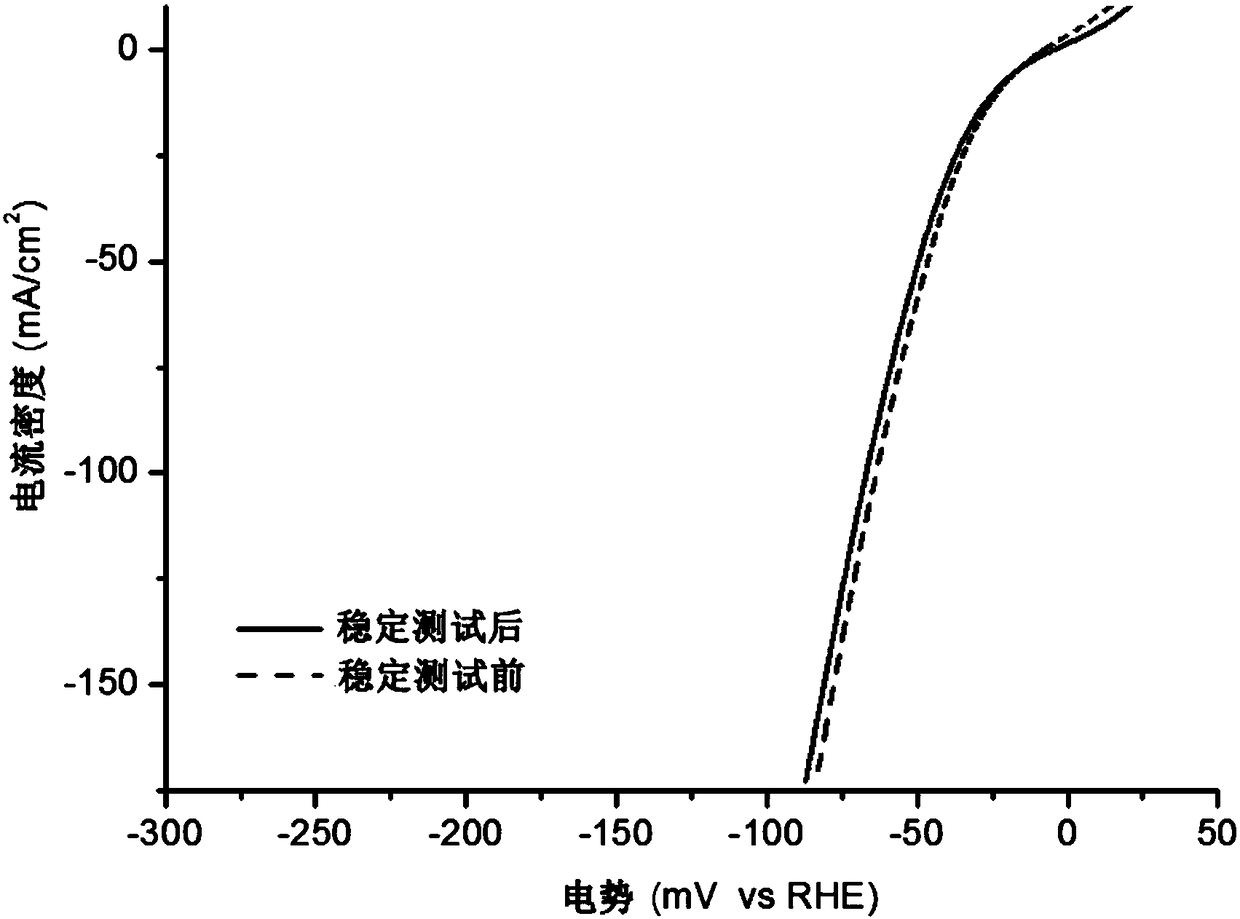

A ni-mo-co, synthesis method technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high overpotential, influence catalyst microstructure, influence catalyst activity, etc., to reduce overpotential, activity and microscopic The effect of structure optimization and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

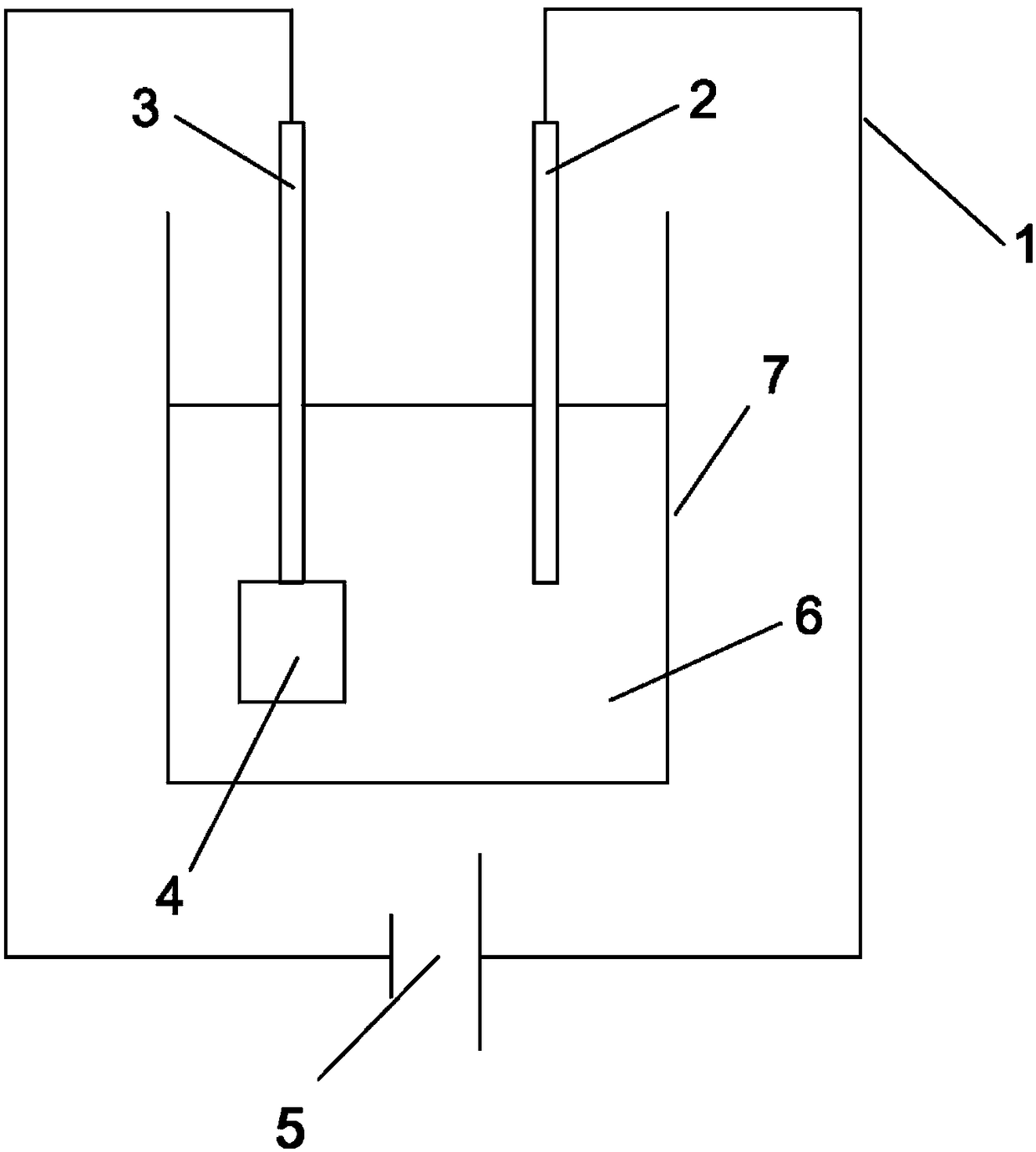

[0045] (1) Preparation of catalyst electroplating solution Take a clean beaker, add chemical reagents as nickel source, molybdenum source, and cobalt source, dissolve in deionized water, and prepare catalyst electroplating solution as follows: 30mmol / L nickel chloride hexahydrate, 8mmol / L sodium molybdate dihydrate, 25mmol / L cobalt nitrate hexahydrate, 100mmol / L sodium pyrophosphate decahydrate and 1300mmol / L sodium bicarbonate; use a magnetic stirrer to stir for 4 hours, and put the catalyst plating solution Stand in air atmosphere for 3 days;

[0046] (2) Substrate cleaning Cut out 1×1cm foamed nickel, put the foamed nickel in concentrated sulfuric acid, and ultrasonicate for 7 minutes at a power of 300w. After ultrasonication, use deionized water, absolute ethanol, and acetone to clean and decontaminate alternately to obtain a clean surface. nickel foam substrate;

[0047] (3) Preparation of template plating solution Use deionized water to make a template plating solution ...

Embodiment 2

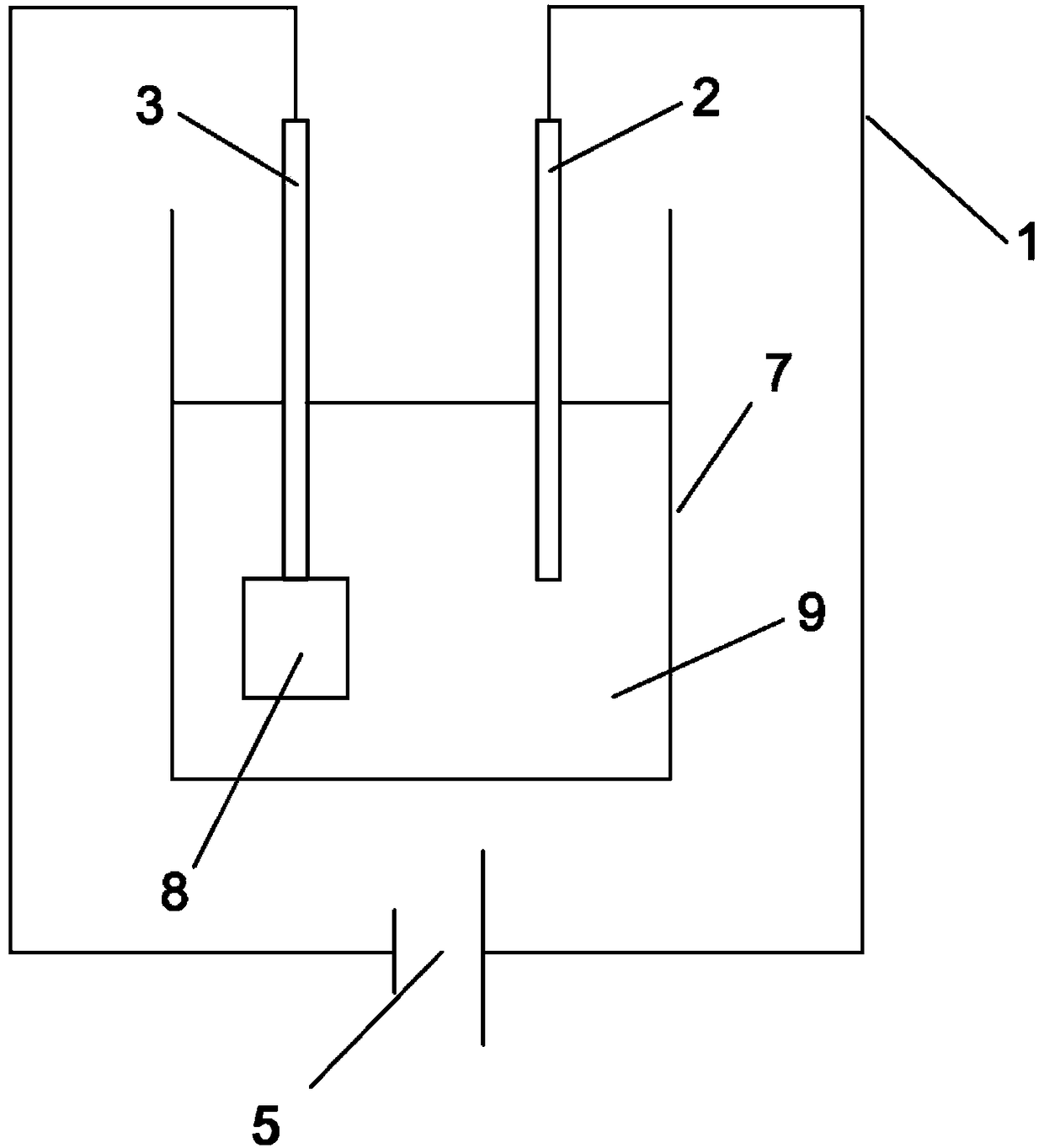

[0052] (1) Preparation of catalyst electroplating solution Take a clean beaker, add chemical reagents as nickel source, molybdenum source, and cobalt source, and dissolve them in deionized water. The components of the prepared catalyst electroplating solution are as follows: 25mmol / L nickel chloride hexahydrate, 20mmol / L sodium molybdate dihydrate, 18mmol / L cobalt nitrate hexahydrate, 75mmol / L sodium pyrophosphate decahydrate and 1500mmol / L sodium bicarbonate; use a magnetic stirrer to stir for 5 hours, and put the catalyst plating solution Stand in air atmosphere for 5 days;

[0053] (2) Substrate cleaning Cut out 1×1cm foamed nickel, put the foamed nickel in concentrated sulfuric acid, and ultrasonicate for 3 minutes at a power of 450w. After ultrasonication, use deionized water, absolute ethanol, and acetone to clean and decontaminate alternately to obtain a clean surface. nickel foam substrate;

[0054] (3) Preparation of template plating solution Use deionized water to m...

Embodiment 3

[0059] (1) Preparation of catalyst electroplating solution Take a clean beaker, add chemical reagents as nickel source, molybdenum source, and cobalt source, dissolve in deionized water, and prepare catalyst electroplating solution as follows: 35mmol / L nickel chloride hexahydrate, 25mmol / L sodium molybdate dihydrate, 12mmol / L cobalt nitrate hexahydrate, 80mmol / L sodium pyrophosphate decahydrate and 600mmol / L sodium bicarbonate; use a magnetic stirrer to stir for 5 hours, and put the catalyst plating solution Stand in air atmosphere for 7 days;

[0060] (2) Substrate cleaning Cut 1×1cm foamed nickel, put the foamed nickel in concentrated sulfuric acid, and ultrasonicate for 5 minutes at a power of 500w. After ultrasonication, use deionized water, absolute ethanol, and acetone to clean and decontaminate alternately to obtain a clean surface. nickel foam substrate;

[0061] (3) Preparation of template plating solution Use deionized water to make a template plating solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com