SCR reactor for improving activity of low-temperature SCR catalyst and inhibiting byproduct N2O

An SCR catalyst and SCR reactor technology, applied in the field of environmental protection flue gas purification, can solve the problems of N2 selectivity decline, ozone layer destruction, energy consumption and other problems, and achieve the effects of simple structure, enhanced denitration effect, and reduced contact time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, now in conjunction with specific embodiments and the technical solutions of the present invention are described in detail below, it should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention scope. In the examples, each original reagent material can be obtained commercially, and the experimental methods without specific conditions are conventional methods and conventional conditions well known in the art, or according to the conditions suggested by the instrument manufacturer.

[0028] In the present invention, the low-temperature SCR catalyst is an existing catalyst, which adopts a V-Mn series catalyst or a catalyst with a similar formulation.

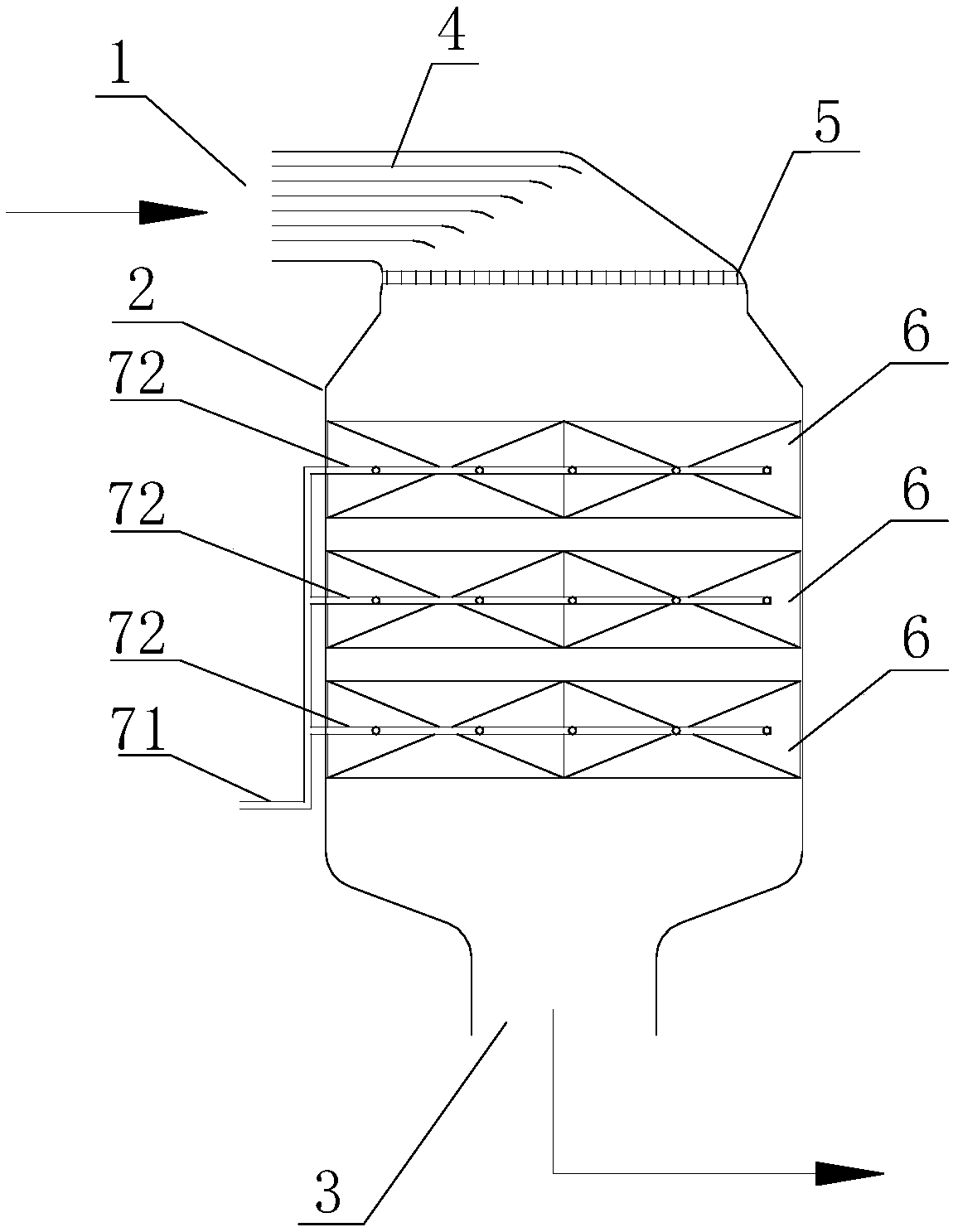

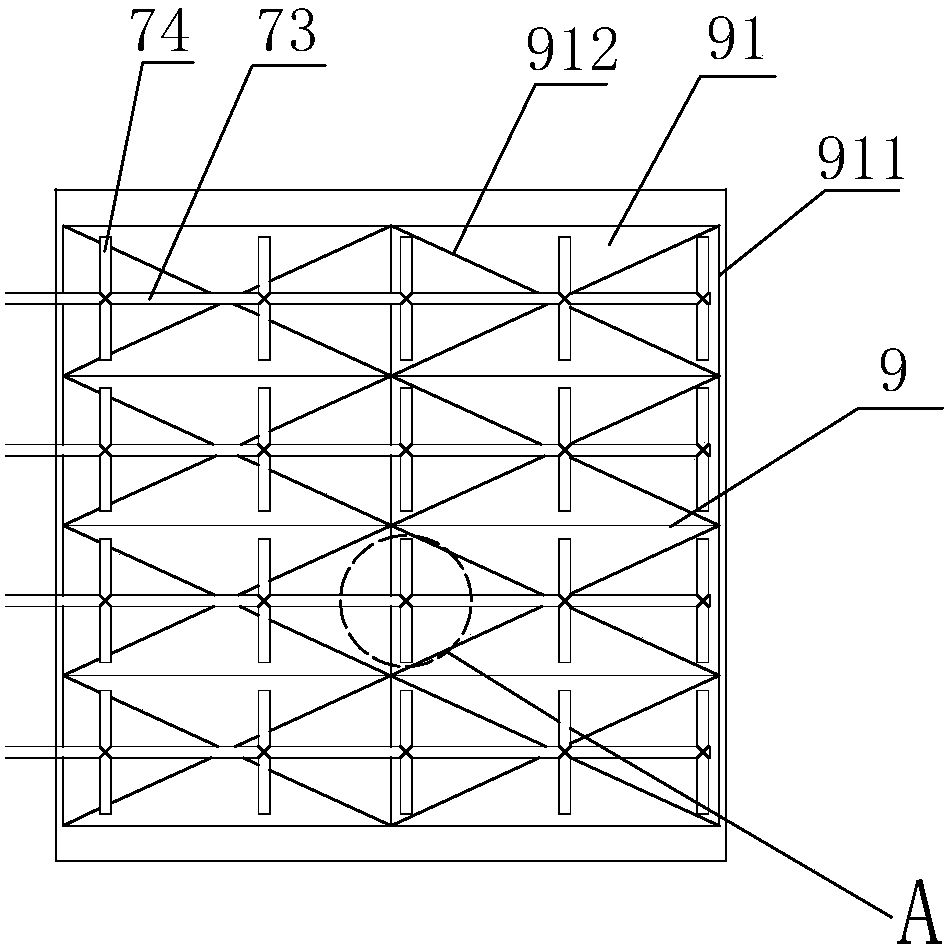

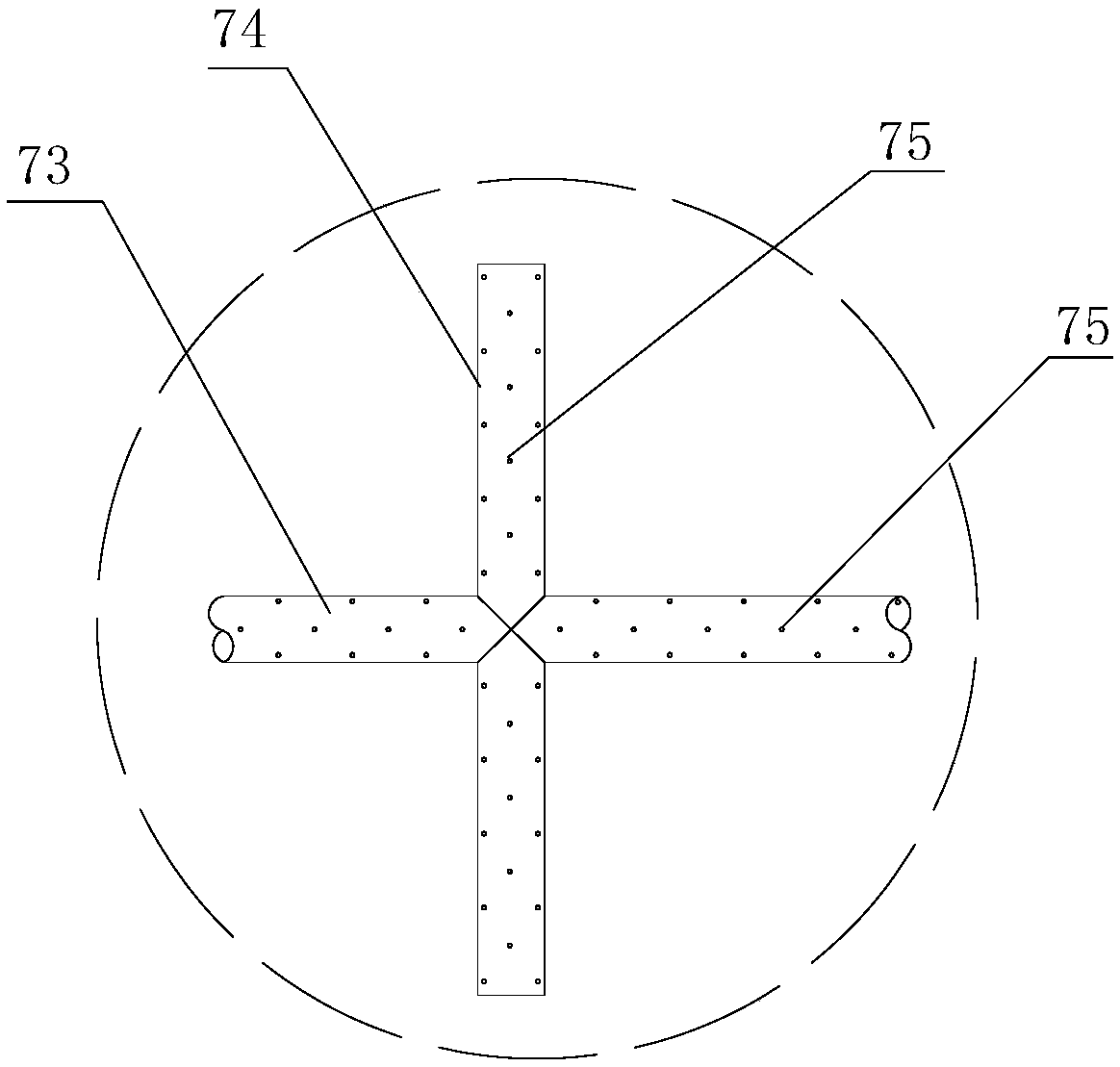

[0029] In the present invention, SCR refers to selective catalytic reduction (selective catalytic reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com