Robot welding process control and multi-sensor signal synchronous acquisition system and method

A welding process and signal synchronization technology, which is applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of few types of sensors and difficulty in ensuring the synchronization of signal acquisition, so as to improve the level of intelligence and facilitate signal analysis and integration to achieve the effect of panoramic monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

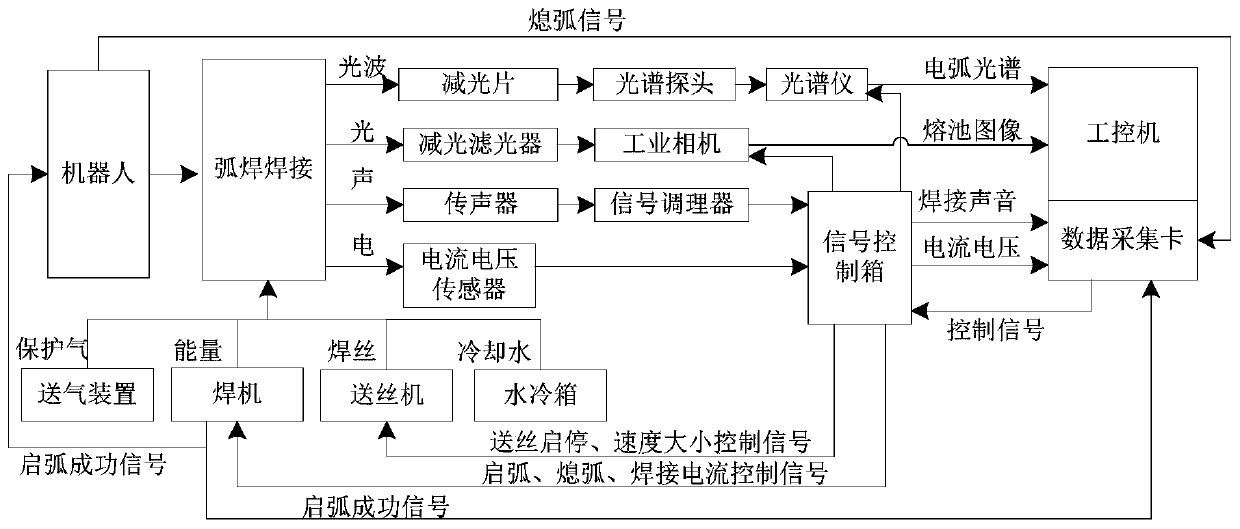

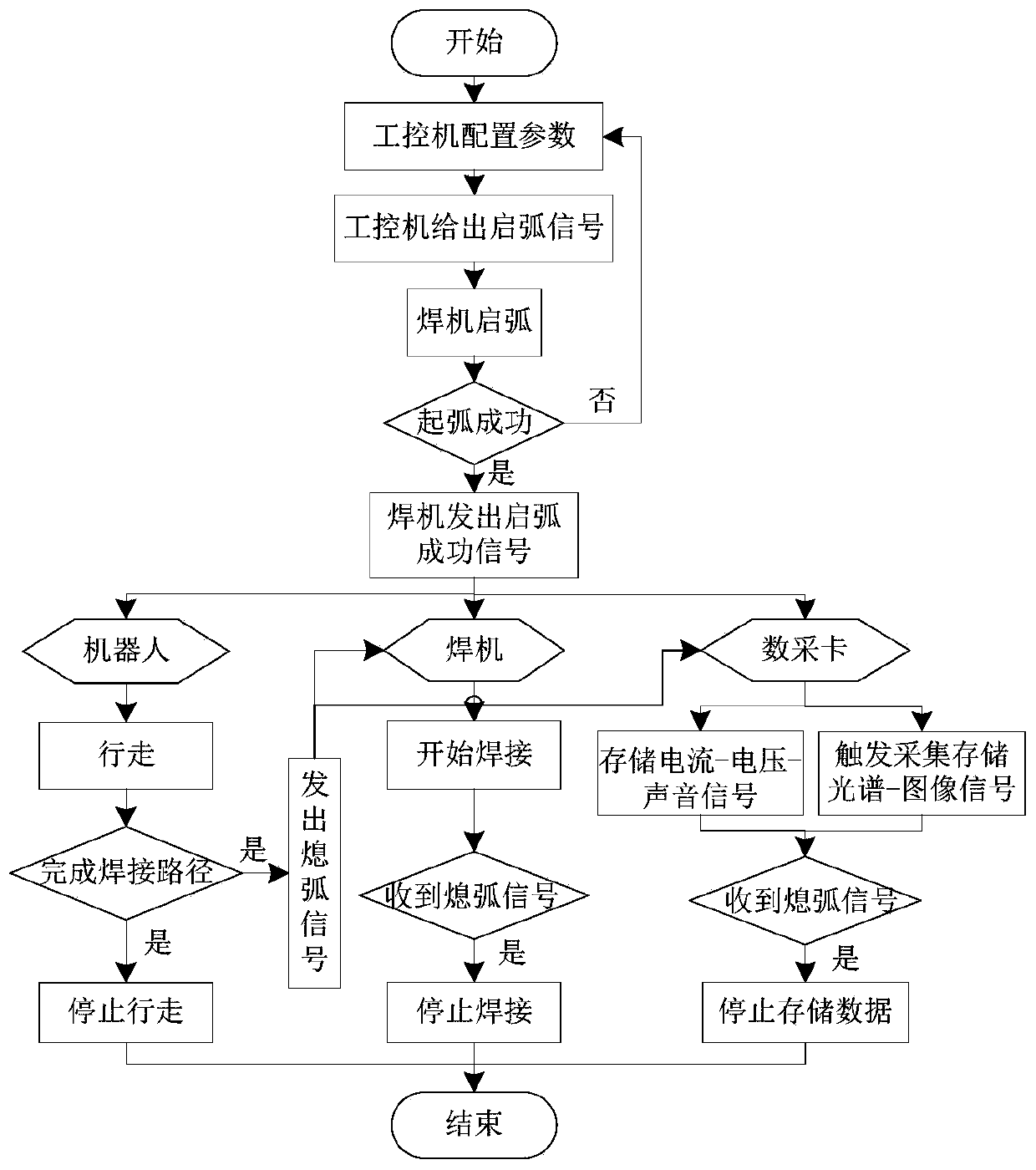

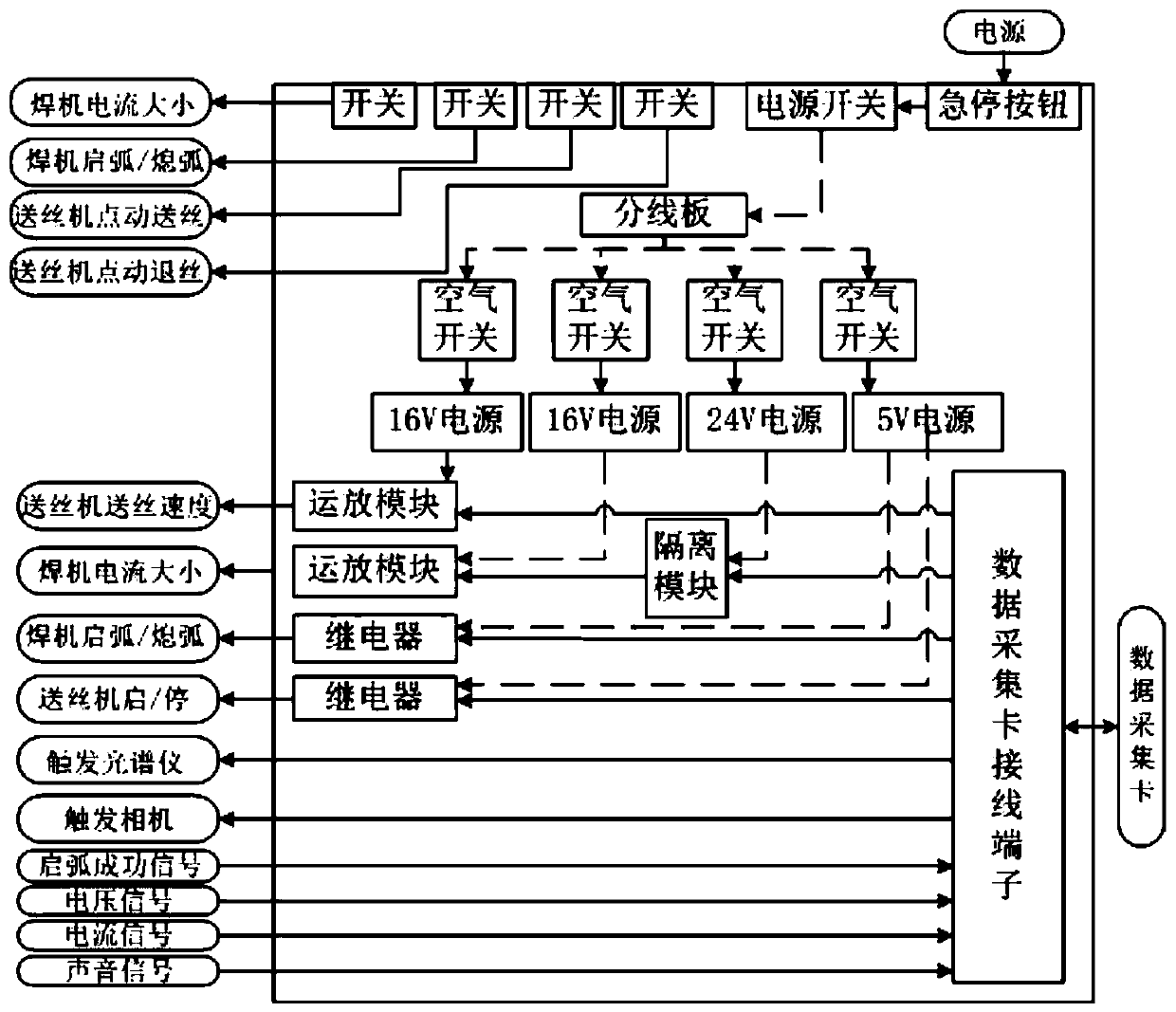

[0029] like figure 1 As shown, the multi-sensing signal acquisition system in the present invention includes a spectral signal acquisition unit, an image signal acquisition unit, a welding sound signal acquisition unit and a current and voltage signal acquisition unit, which can realize arc spectrum, molten pool image, and welding sound during welding. And current and voltage multi-sensing signals are collected synchronously, where synchronous collection refers to the simultaneous collection of each signal at the beginning of welding, with the same time axis, but the frequency of signal collection can be different; the control system is composed of industrial computer, data acquisition card and control box , can realize welding process control, including wire feeding start and stop and speed, welding machine arc start, arc extinguish, welding current control, and signa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com