HMX (octogen) surface coating sensitivity decreasing method

A surface coating and desensitization technology, applied in non-explosive/non-thermal agent components, non-explosive desensitizers/passivators, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the cost High, cumbersome coating process, not environmentally friendly, etc., to achieve the effect of reduced mechanical sensitivity and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

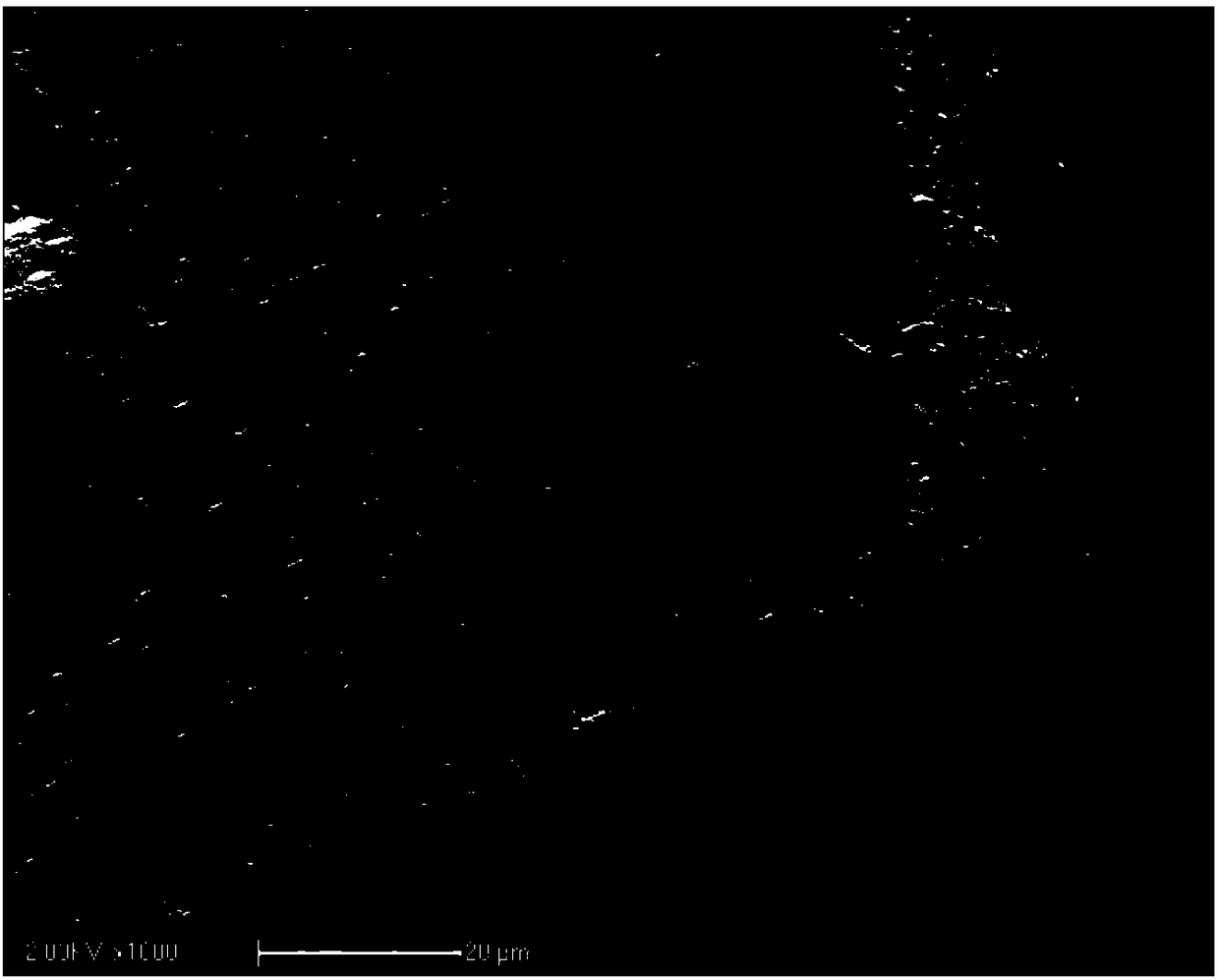

Image

Examples

Embodiment 1

[0018] (1) Take by weighing 0.1g tannic acid solid, dissolve in 2.5ml water, prepare the tannic acid aqueous solution that concentration is 40mg / ml;

[0019] (2) Take by weighing 0.025g ferric chloride solid, be dissolved in 2.5ml water, the preparation concentration is the ferric chloride aqueous solution of 10mg / ml;

[0020] (3) Add 1g of HMX particles into the tannic acid aqueous solution and stir rapidly, the stirring rate is 500r / min, and the stirring time is 100s, then add the ferric chloride aqueous solution, and continue stirring for 100s;

[0021] (4) dripping concentration gradually is the sodium hydroxide aqueous solution of 0.1mol / L, and the pH value of the mixed solution described in (3) is adjusted to be 8;

[0022] (5) Washing with water, filtering, separating and drying the HMX particles at a drying temperature of 50° C. to obtain HMX particles coated with desensitization on the surface. The characteristic drop height of HMX has been increased from 32.0cm to 5...

Embodiment 2

[0024] (1) Take by weighing 0.4g tannic acid solid, be dissolved in 20ml water, the preparation concentration is the tannic acid aqueous solution of 20mg / ml;

[0025] (2) Take by weighing 0.1g ferric chloride solid, be dissolved in 20ml water, prepare the ferric chloride aqueous solution that concentration is 5mg / ml;

[0026] (3) Add 0.5g of HMX particles into the ferric chloride aqueous solution and stir rapidly, the stirring rate is 400r / min, and the stirring time is 10s, then add the tannic acid aqueous solution, and continue stirring for 10s;

[0027] (4) Gradually drip the tris aqueous solution whose concentration is 0.5mol / L, and adjust the pH value of the mixed solution described in (3) to be 8.5;

[0028] (5) Washing with water, filtering, separating and drying the HMX particles at a drying temperature of 70° C. to obtain HMX particles coated with desensitization on the surface.

Embodiment 3

[0030] (1) Take by weighing 0.2g tannic acid solid, dissolve in 20ml water, prepare the tannic acid aqueous solution that concentration is 10mg / ml;

[0031] (2) Take by weighing 0.1g ferric chloride solid, be dissolved in 20ml water, prepare the ferric chloride aqueous solution that concentration is 5mg / ml;

[0032] (3) Add 20g of HMX particles into the ferric chloride aqueous solution and stir rapidly, the stirring rate is 800r / min, the stirring time is 200s, then add the tannic acid aqueous solution, and continue stirring for 200s;

[0033] (4) dripping the ammonia solution whose concentration is 0.5mol / L step by step, adjust the pH value of the mixed solution described in (3) to be 9;

[0034] (5) Washing with water, filtering, separating and drying the HMX particles at a drying temperature of 60° C. to obtain HMX particles coated with desensitization on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com