A kind of low drug adsorption TPS and its preparation method and application

A drug and reaction technology, applied in the field of medical device materials, can solve the problems of reducing drug efficacy, inability to apply fat-soluble and water-soluble drugs at the same time, and achieve the effects of no pollution to the environment, easy large-scale continuous production, and not easy to precipitate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the above-mentioned low drug adsorption TPS, comprising the following steps:

[0031] After the pre-irradiated TPS is mixed with one of the organic peroxide initiators, TPS and reactive vinyl fluorosilicone oil, the low drug adsorption TPS is obtained through melt grafting reaction.

[0032] In the present invention, firstly, the pre-irradiated TPS is mixed with one of the organic peroxide initiators, TPS and reactive vinyl fluorosilicone oil to obtain a mixture.

[0033] In the present invention, the preparation of raw materials may also include auxiliary grafting monomers, that is, mixing pre-irradiated TPS with one of the organic peroxide initiators, TPS and reactive vinyl fluorosilicone oil to obtain a mixture.

[0034] After obtaining the mixture, the mixture is subjected to melt grafting reaction to obtain TPS with low drug adsorption.

[0035] The temperature of the melting grafting reaction is 160-240°...

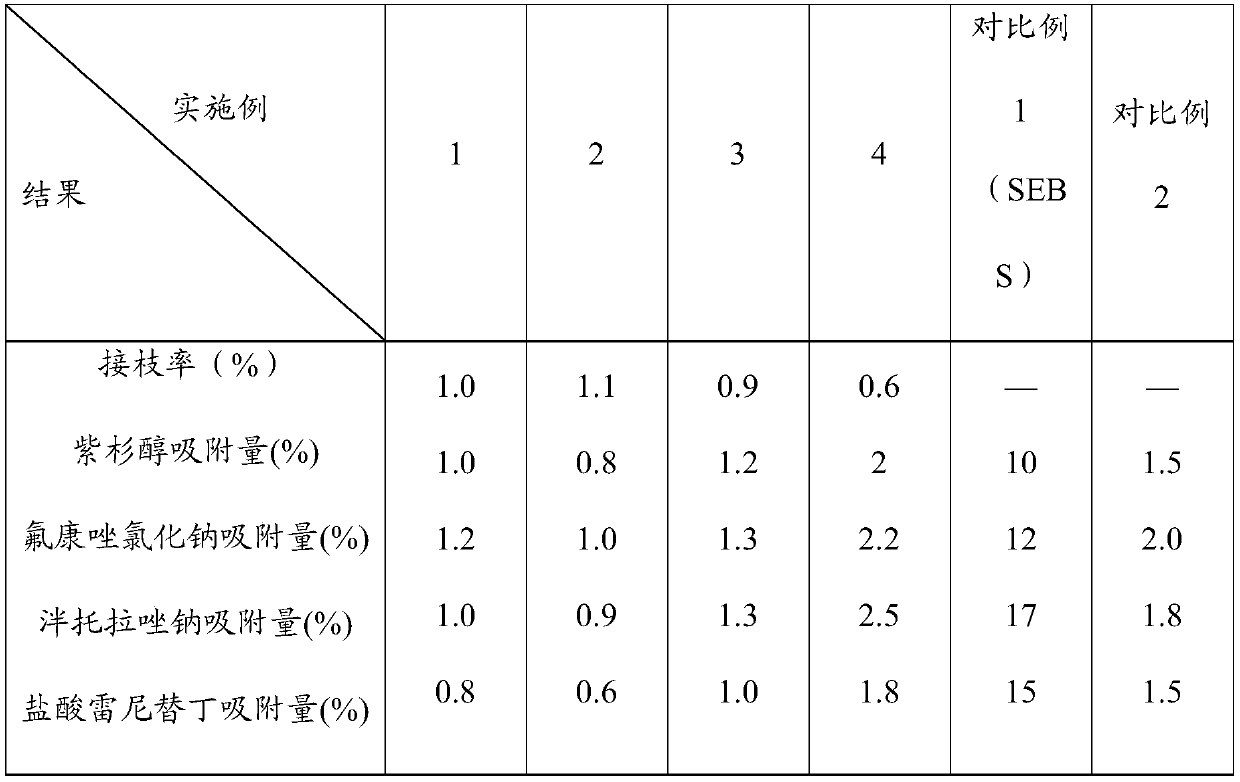

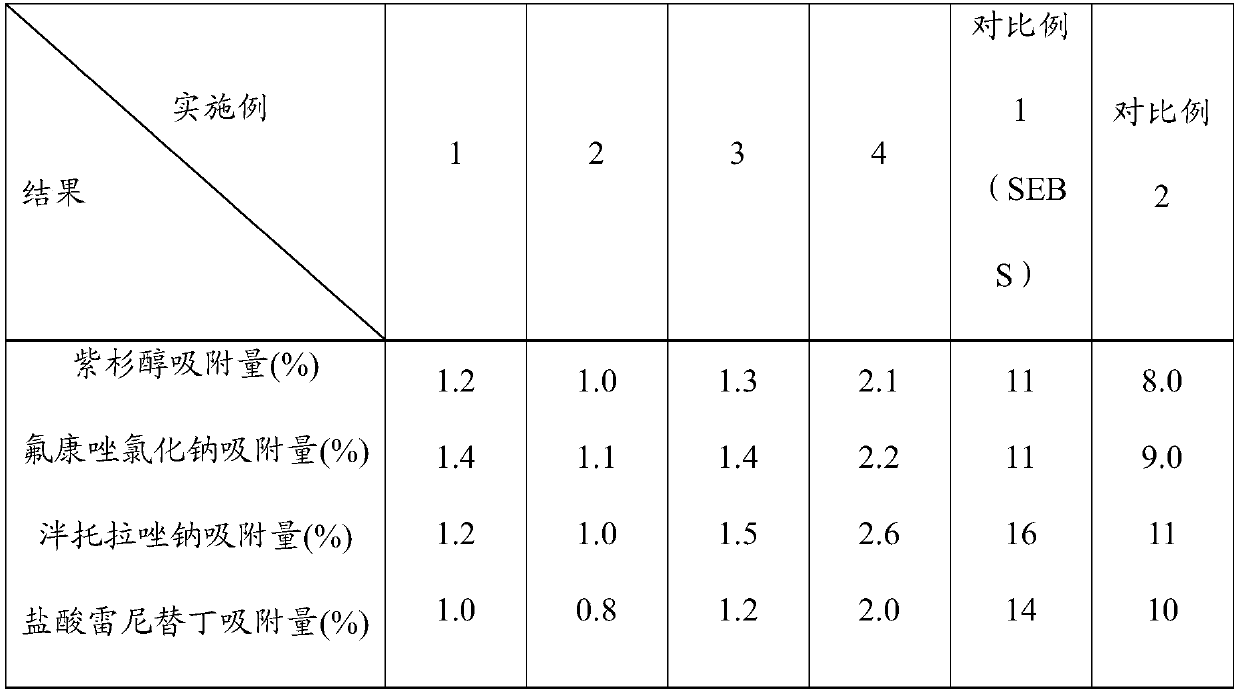

Embodiment 1

[0042] Weigh 1000 grams of SEBS ( G1652), 15 grams of vinyl fluorosilicone oil (viscosity: 2000cp), 5 grams of dicumyl peroxide initiator and 12 grams of styrene are mixed in a high mixer, and then the blend is melted in a twin-screw Reactive extrusion yields low drug adsorption SEBS. The reaction extrusion grafting temperature is 200° C., the screw speed is 150 rpm, and the material residence time is 1.2 min. The modified SEBS was used to prepare corresponding disposable infusion tubes, and the adsorption properties of various drugs are listed in Table 1.

Embodiment 2

[0044] Weigh 1000 grams of SEPS ( G1650 M), 20 grams of vinyl fluorosilicone oil (viscosity: 4000cp), 4 grams of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane initiator and 8 grams of vinylpyrrolidone in a high mixer The mixture was mixed in a twin-screw, and then the blend was melt-reactively extruded in a twin-screw to obtain SEPS with low drug adsorption performance. The reaction extrusion grafting temperature is 190° C., the screw speed is 100 rpm, and the material residence time is 2.5 minutes. The modified SEPS was prepared into corresponding disposable infusion tubes, and the adsorption properties of various drugs are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com