Modified polysilazane prepolymer, modified polysilazane coating and usage method of modified polysilazane coating

A polysilazane, prepolymer technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve problems such as difficult degradation, biological and environmental hazards, and achieve smoothness, good hand feel, and good adhesion. , smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

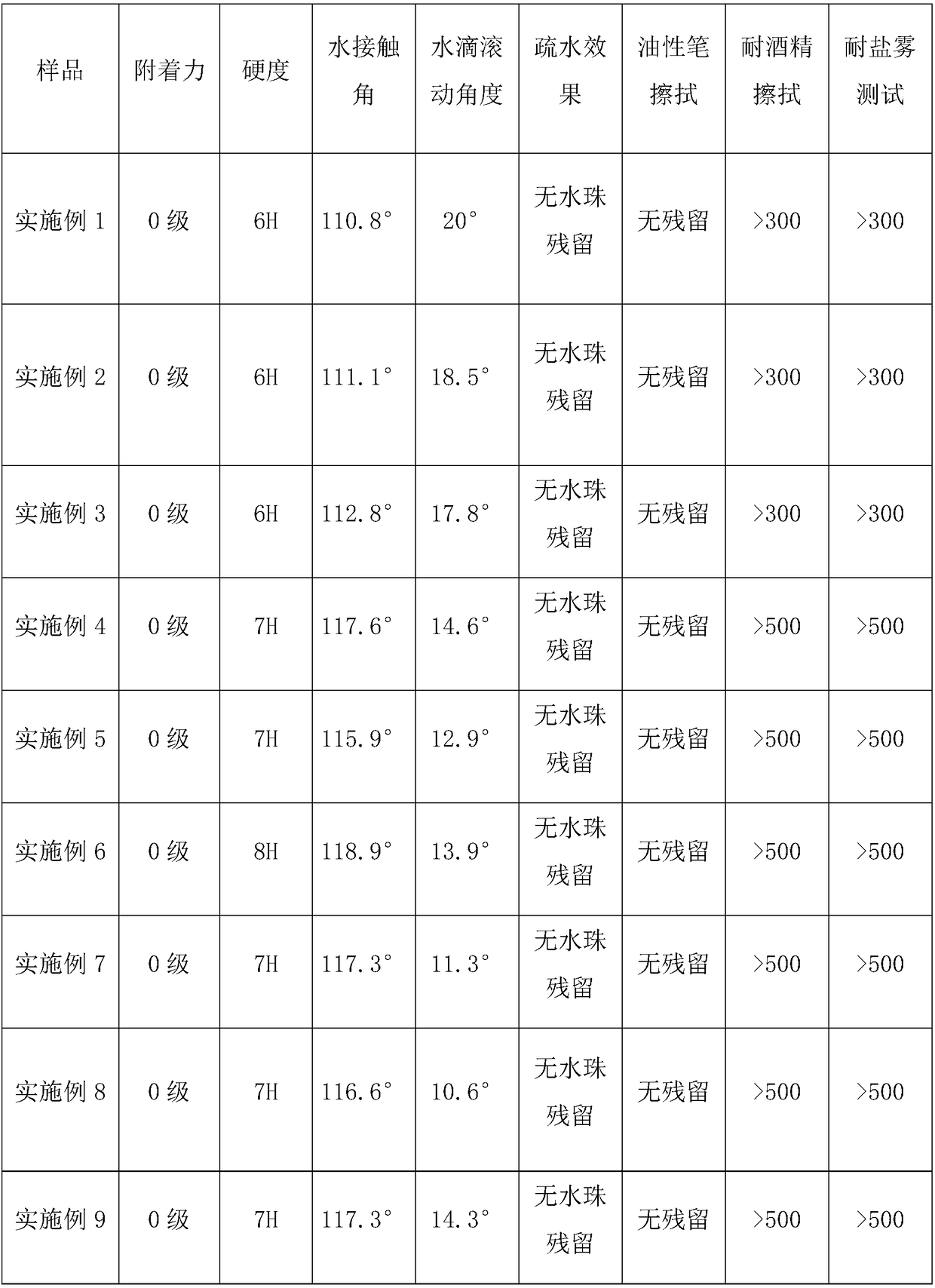

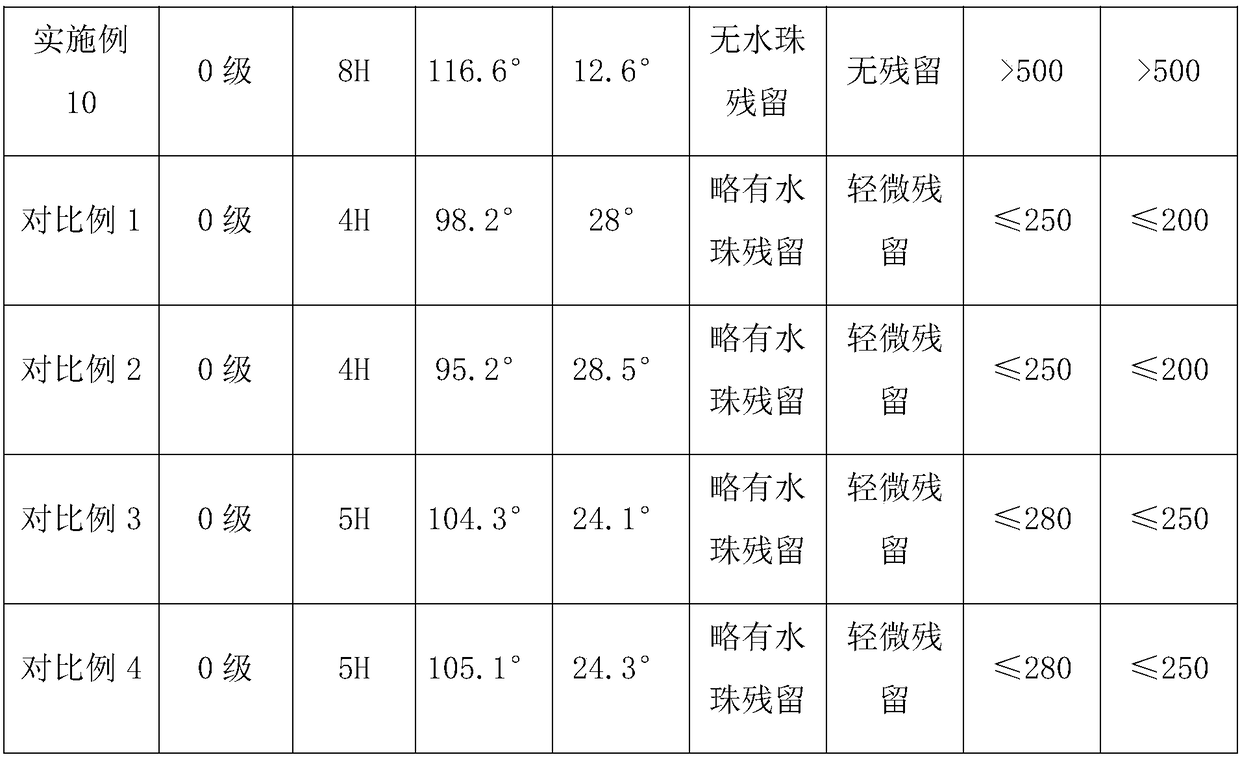

Examples

Embodiment 1

[0069] Add 0.05 parts of perfluoropolyether alcohol, 40 parts of polysilazane and 0.0001 part of palladium acetylacetonate into the reactor and mix them uniformly, then react at 95°C for 2 hours to obtain modified polysilazane modified by perfluoropolyether alkane prepolymer; wherein, the polysilazane is represented by the following formula:

[0070] -(SiR 1 R 2 -NR 3 ) n -, where R 1 for hydrogen, R 2 is an alkyl group, R 3 for vinyl.

[0071] (2) 5 parts of the modified polysilazane prepolymer prepared in step (1) and 20 parts of butyl acetate were mixed and stirred at room temperature until the mixture was uniform to obtain the modified polysilazane coating.

[0072] (3) The modified polysilazane coating prepared in step (2) was flow-coated on the tinplate panel, and moisture-cured at 80° C. for 180 minutes; then cooled to room temperature to obtain the modified polysilazane coating.

Embodiment 2

[0074] (1) Add 10 parts of perfluoropolyether alcohol, 70 parts of polysilazane and 0.0003 parts of tetrabutylammonium fluoride into the reactor and mix evenly, then react at 70°C for 5 hours to obtain perfluoropolyether-modified A modified polysilazane prepolymer; wherein, the polysilazane is represented by the following formula:

[0075] -(SiR 1 R 2 -NR 3 ) n -, where R 1 is an alkyl group, R 2 for vinyl, R 3 for vinyl.

[0076] (2) 50 parts of the modified polysilazane prepolymer prepared in the step (1) and 60 parts of butyl acetate were mixed and stirred at room temperature until the mixture was uniform to obtain the modified polysilazane coating.

[0077] (3) The modified polysilazane coating prepared in step (2) was flow-coated on the tinplate panel, and moisture-cured at 180° C. for 100 minutes; then cooled to room temperature to obtain the modified polysilazane coating.

Embodiment 3

[0079] (1) 20 parts of perfluoropolyether alcohols, 100 parts of polysilazane and 0.0003 parts by mass of 2,4-lutidine and 0.0002 parts by mass of dicumyl peroxide are added to the reactor and mixed uniformly, then React at 20°C for 10 hours to obtain a modified polysilazane prepolymer modified by perfluoropolyether; wherein, the polysilazane is represented by the following formula:

[0080] -(SiR 1 R 2 -NR 3 ) n -, where R 1 for hydrogen, R 2 is an alkyl group, R 3 is a trialkoxysilylalkyl group.

[0081] (2) 80 parts of the modified polysilazane prepolymer prepared in step (1) and 95 parts of butyl acetate were mixed and stirred at room temperature until uniformly mixed to obtain a modified polysilazane coating.

[0082] (3) The modified polysilazane coating prepared in step (2) was flow-coated on the tinplate panel, and cured by moisture at 250° C. for 20 minutes; then cooled to room temperature to obtain the modified polysilazane coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com