Preparation method of high-performance nylon nanocomposite

A nano-composite material and high-performance technology, applied in the field of preparation of high-performance nylon nano-composite materials, can solve the problems of high cost of industrialized materials, high price of nano-modifier POSS, limited improvement of mechanical properties of nano-materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

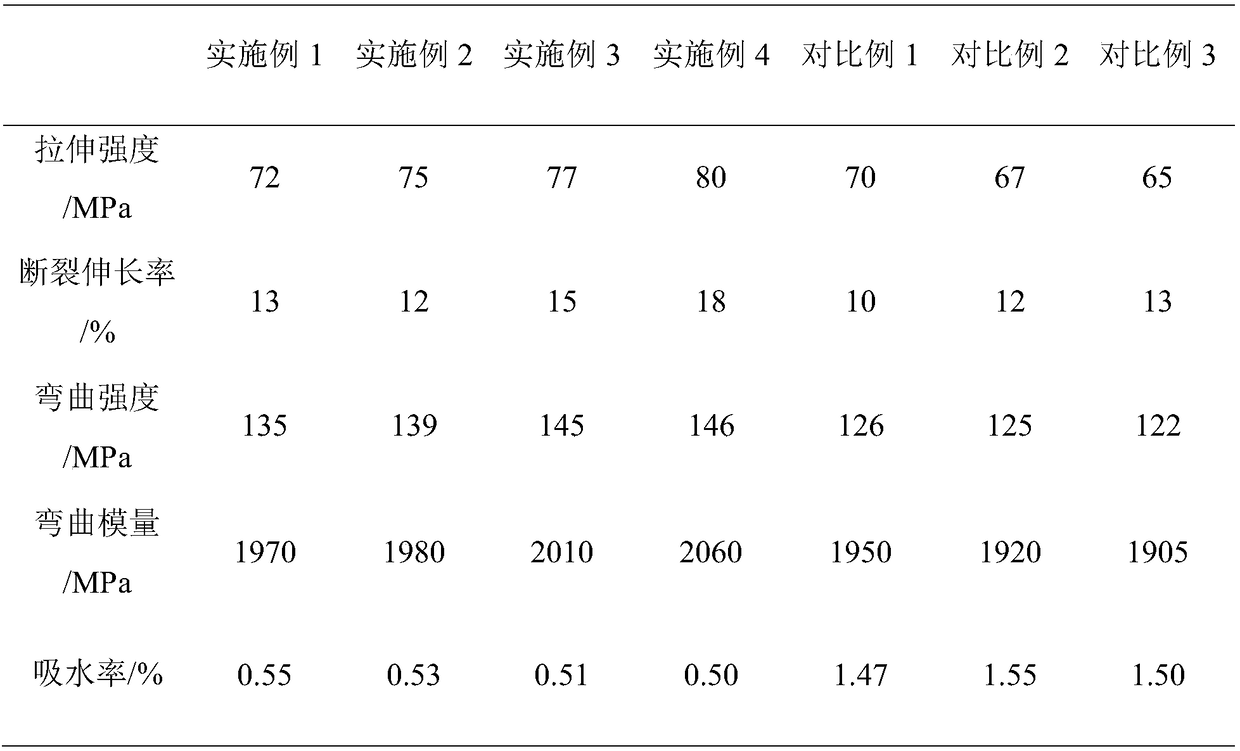

Examples

Embodiment 1

[0036] A nylon composite material is prepared by drying nylon 6 and silica grafted polyamino acid nanoparticles at 80℃-90℃ for 8-10 hours; according to the weight ratio, 100 parts have been dried Nylon 6, 3 parts of silica grafted polyamino acid nanoparticles (NCA monomer and aminated SiO 2 -NH 2 The ratio is 0.5:1), 0.8 parts of antioxidant, 0.5 parts of processing aid ethylene bis-stearamide (EBS), fully stirred to obtain the compound, and the above-mentioned ingredients are passed through the extruder at 250-270℃ Next, the nano particles and nylon 6 are blended and granulated to obtain a high-performance nylon 6 nanocomposite material.

Embodiment 2

[0038] A nylon composite material is prepared by drying nylon 6 and silica grafted polyamino acid nanoparticles at 80℃-90℃ for 8-10 hours; according to the weight ratio, 100 parts have been dried Nylon 6, 3 parts of silica grafted polyamino acid nanoparticles (NCA monomer and aminated SiO 2 -NH 2 The ratio is 1:1), 0.8 parts of antioxidant, 0.5 parts of processing aid ethylene bisstearamide (EBS), fully stirred to obtain the compound, and the above-mentioned ingredients are passed through the extruder at 250-270℃ Next, the nano particles and nylon 6 are blended and granulated to obtain a high-performance nylon 6 nanocomposite material.

Embodiment 3

[0040] A nylon composite material is prepared by drying nylon 6 and silica grafted polyamino acid nanoparticles at 80℃-90℃ for 8-10 hours; according to the weight ratio, 100 parts have been dried Nylon 6, 3 parts of silica grafted polyamino acid nanoparticles (NCA monomer and aminated SiO 2 -NH 2 The ratio is 2:1), 0.8 parts of antioxidant, 0.5 parts of processing aid ethylene bis-stearamide (EBS), fully stirred to obtain the compound, and the above-mentioned ingredients are passed through the extruder at 250-270℃ Next, the nano particles and nylon 6 are blended and granulated to obtain a high-performance nylon 6 nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com