Waterproof and decorative integrated coating and preparation method thereof

A coating and powder technology, which is applied in waterproof and decorative integrated coatings. The waterproof and decorative integrated coatings preparation field can solve the problems of weak weather resistance and efflorescence resistance of the base surface, affecting the appearance of the coating, and destroying the waterproof layer. , to achieve the effect of reducing the risk of cracking, high cost performance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

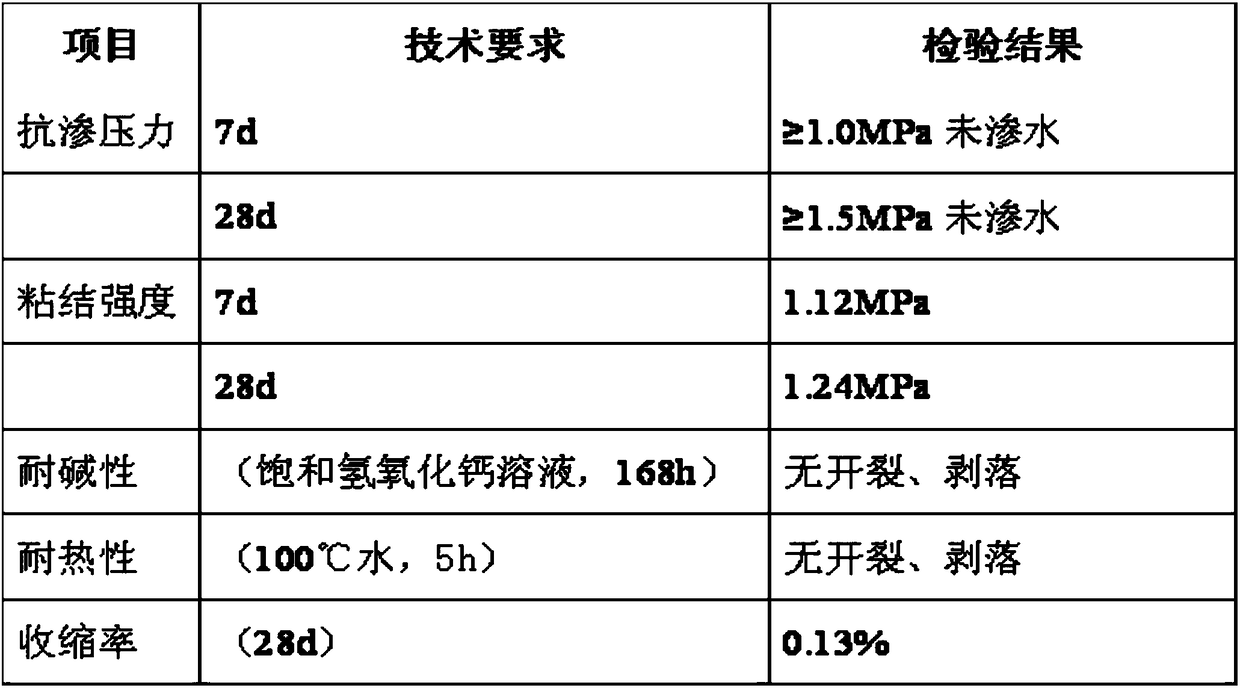

Embodiment 1

[0015] The preparation method of waterproof decoration integrated paint of the present invention comprises the following steps:

[0016] (1) Powder: Weigh 28 parts of white cement (42.5), 34 parts of white quartz sand (80-100 mesh), 20 parts of white quartz powder (200 mesh), 0.3 part of cellulose ether (viscosity 15000MPa.s), Dispersible latex powder 8034 2.5 parts, white wood fiber C500 0.5 parts, Yilaitai SEAL80 water repellent 0.3 parts, white micro-silica fume (fineness 2000 mesh) 8 parts, powder defoamer 803 0.4 parts, iron oxide pigment 0.1 share;

[0017] Weigh all the powders in proportion and add them to the horizontal dry mixing equipment for stirring, stir for 5 minutes evenly and then pack;

[0018] (2) Liquid material: 40 parts of pure acrylic emulsion (small molecule), 30 parts of VAE emulsion, 10 parts of deionized water, 2 parts of dispersant, 2 parts of defoamer;

[0019] Weigh each component of the liquid material in proportion and add it to the paint disp...

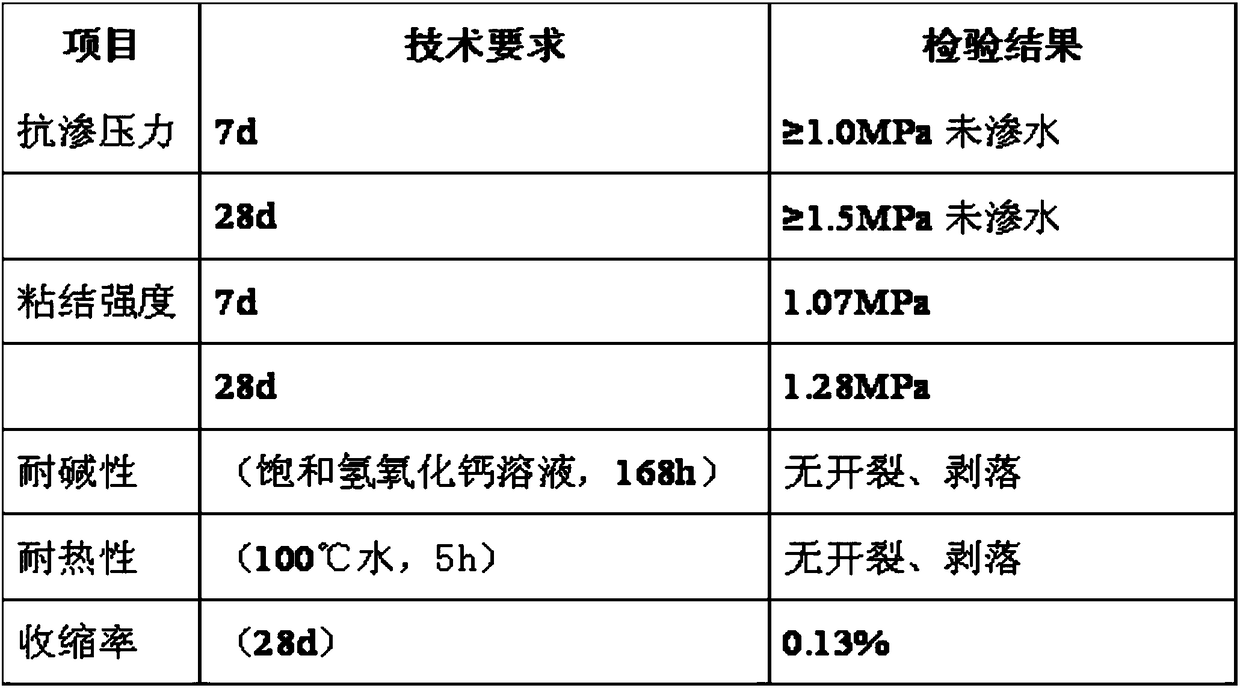

Embodiment 2

[0027] The preparation method of waterproof decoration integrated paint of the present invention comprises the following steps:

[0028] (1) Powder: Weigh 18 parts of white cement (42.5), 30 parts of white quartz sand (80-100 mesh), 30 parts of white quartz powder (200 mesh), 0.3 part of cellulose ether (viscosity 15000MPa.s), Dispersible latex powder 8034 2.5 parts, white wood fiber C500 0.5 parts, Yilaitai SEAL80 water repellent 0.3 parts, white micro-silica fume (fineness 2000 mesh) 8 parts, powder defoamer 803 0.4 parts, iron oxide pigment 2 share;

[0029] Weigh all the powders in proportion, add them to the horizontal dry mixing equipment and stir, stir for 10 minutes evenly and pack;

[0030] (2) Liquid material: 55 parts of pure acrylic emulsion (small molecule), 40 parts of VAE emulsion, 20 parts of deionized water, 2 parts of dispersant, 2 parts of defoamer;

[0031] Weigh each component of the liquid material in proportion and add it to the paint disperser for low...

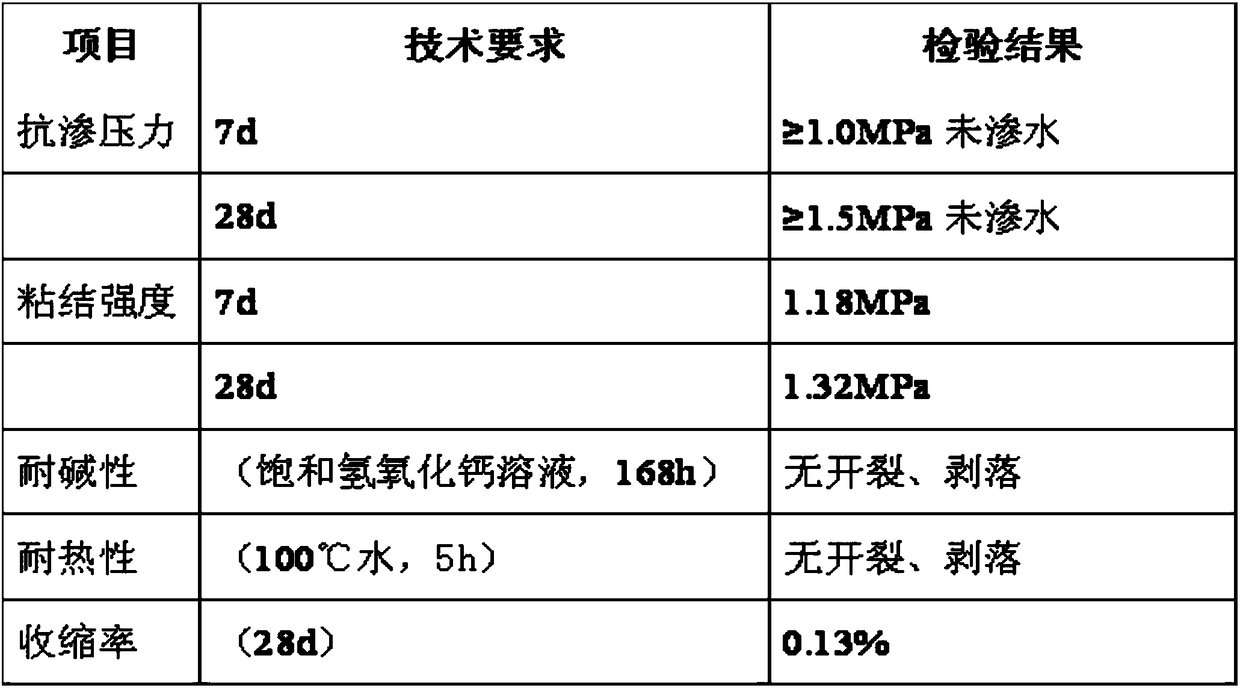

Embodiment 3

[0039] The preparation method of waterproof decoration integrated paint of the present invention comprises the following steps:

[0040] (1) Powder: Weigh 24 parts of white cement (42.5), 40 parts of white quartz sand (80-00 mesh), 25 parts of white quartz powder (200 mesh), 0.3 parts of cellulose ether (viscosity 15000MPa.s), can 2.5 parts of dispersed latex powder 8034, 0.5 parts of white wood fiber C500, 0.3 parts of Yilaitai SEAL80 water repellent, 8 parts of white micro-silica powder (fineness 2000 mesh), 8030.4 parts of powder defoamer, 5 parts of iron oxide pigment;

[0041] Weigh all the powders in proportion and add them to the horizontal dry mixing equipment for stirring, stir for 8 minutes and pack them evenly;

[0042] (2) Liquid material: 60 parts of pure acrylic emulsion (small molecule), 35 parts of VAE emulsion, 15 parts of deionized water, 2 parts of dispersant, 2 parts of defoamer;

[0043] Weigh each component of the liquid material in proportion and add it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com