Magnesia titanium alloy plate and preparation method thereof

A magnesium-titanium alloy plate and magnesium-titanium alloy technology, applied in the field of alloys, can solve the problems of high hardness requirements and difficulty in making building plates, etc., achieve excellent performance, improve melting efficiency, and improve the plasticity of the alloy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

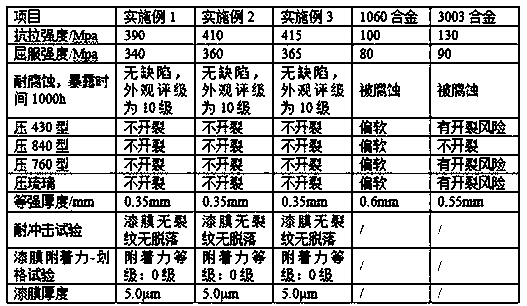

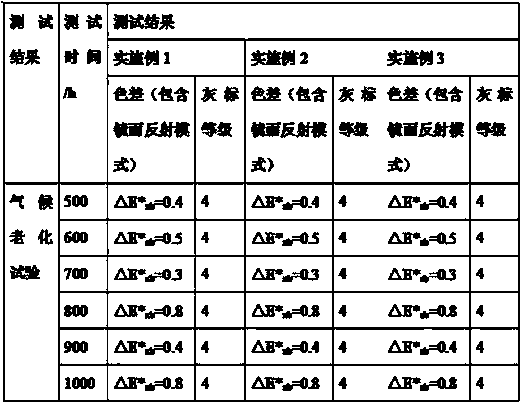

Embodiment 1

[0035] Magnesium-titanium alloy plate, including the following components by weight percentage: zinc 0.10%, chromium 0.05%, silicon 0.06%, iron 0.008%, manganese 0.3%, magnesium 4.2%, titanium 0.18%, copper 0.12%, erbium 0.6% , Vanadium 0.10%, antimony 0.3%, molybdenum 0.02%, calcium 0.2%, cerium 0.3%, the balance is aluminum.

[0036] The thickness of the magnesium-titanium alloy plate is 0.25 mm.

[0037] The surface of the magnesium-titanium alloy plate is coated with a paint film, the paint film is coated with a metallic paint, and the metallic paint is Nippon Paint QA-766 fluorocarbon metallic paint.

[0038] The preparation method of the magnesium-titanium alloy plate includes the following steps:

[0039] Step 1. Material preparation:

[0040] Prepare the first mixture:

[0041] Mix the following components uniformly according to the weight percentage: aluminum, zinc, chromium, silicon, iron, manganese, magnesium and copper to obtain the first mixture;

[0042] Mix the following c...

Embodiment 2

[0054] The magnesium-titanium alloy plate includes the following components in weight percentage: zinc 0.18%, chromium 0.09%, silicon 0.11%, iron 0.009%, manganese 0.38%, magnesium 4.8%, titanium 0.24%, copper 0.21%, erbium 0.5%, Vanadium 0.16%, antimony 0.4%, molybdenum 0.12%, calcium 0.28%, cerium 0.4%, and the balance is aluminum.

[0055] The thickness of the magnesium-titanium alloy plate is 1.5 mm.

[0056] The surface of the magnesium-titanium alloy plate is coated with a paint film, the paint film is coated with a metallic paint, and the metallic paint is Nippon Paint QA-766 fluorocarbon metallic paint.

[0057] The preparation method of the magnesium-titanium alloy plate includes the following steps:

[0058] Step 1. Material preparation:

[0059] Prepare the first mixture:

[0060] Mix the following components uniformly according to the weight percentage: aluminum, zinc, chromium, silicon, iron, manganese, magnesium and copper to obtain the first mixture;

[0061] Mix the follo...

Embodiment 3

[0073] Magnesium-titanium alloy plate, including the following components by weight percentage: zinc 0.25%, chromium 0.11%, silicon 0.20%, iron 0.010%, manganese 0.42%, magnesium 5.4%, titanium 0.26%, copper 0.25%, erbium 3% , Vanadium 0.2%, antimony 0.5%, molybdenum 0.32%, calcium 0.4%, cerium 0.5%, and the balance is aluminum.

[0074] The thickness of the magnesium-titanium alloy plate is 3.0 mm.

[0075] The surface of the magnesium-titanium alloy plate is coated with a paint film, the paint film is coated with a metallic paint, and the metallic paint is Nippon Paint QA-766 fluorocarbon metallic paint.

[0076] The preparation method of the magnesium-titanium alloy plate includes the following steps:

[0077] Step 1. Material preparation:

[0078] Prepare the first mixture:

[0079] Mix the following components uniformly according to the weight percentage: aluminum, zinc, chromium, silicon, iron, manganese, magnesium and copper to obtain the first mixture;

[0080] Mix the following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com