Pulsed laser deposition device and method thereof

A pulsed laser deposition and laser technology, which is applied in the laser field, can solve problems such as large particles, thin films affecting crystallization performance, and large fluctuations in plasma components, so as to reduce the generation of droplets, improve crystallization performance and uniformity, The effect of reducing foreign particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

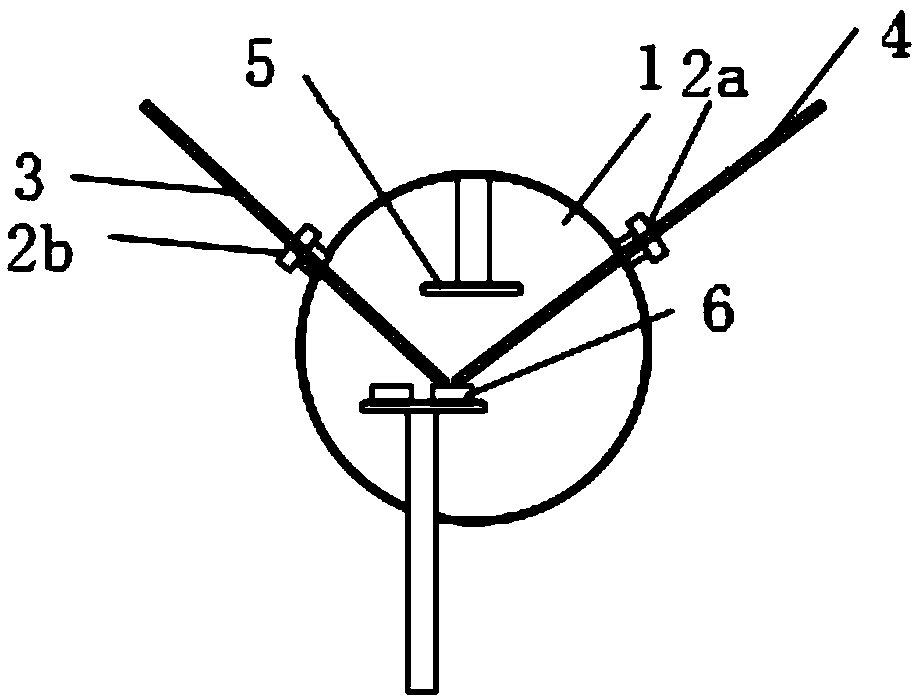

[0029] figure 1 The structure of a pulsed laser deposition device provided for the embodiment of the present application, pulsed laser deposition (PulsedLaser Deposition, PLD), also known as pulsed laser ablation (pulsed laser ablation, PLA), is a method of using laser to process objects Bombardment, and then deposit the bombarded substances on different substrates to obtain a means of precipitation or thin film. That is, the high-power pulsed laser is focused on the surface of the target to generate high temperature and ablation on the surface, and further generate high-temperature and high-pressure plasma. , and finally the ablative is deposited on the front substrate to form a thin film. Due to the high energy of the laser, refractory thin films can be deposited, making it possible to deposit almost all existing thin film materials and maintain the stoichiometric composition of the target. like figure 1 As shown, the structure includes:

[0030] A chamber 1, the chamber...

Embodiment 2

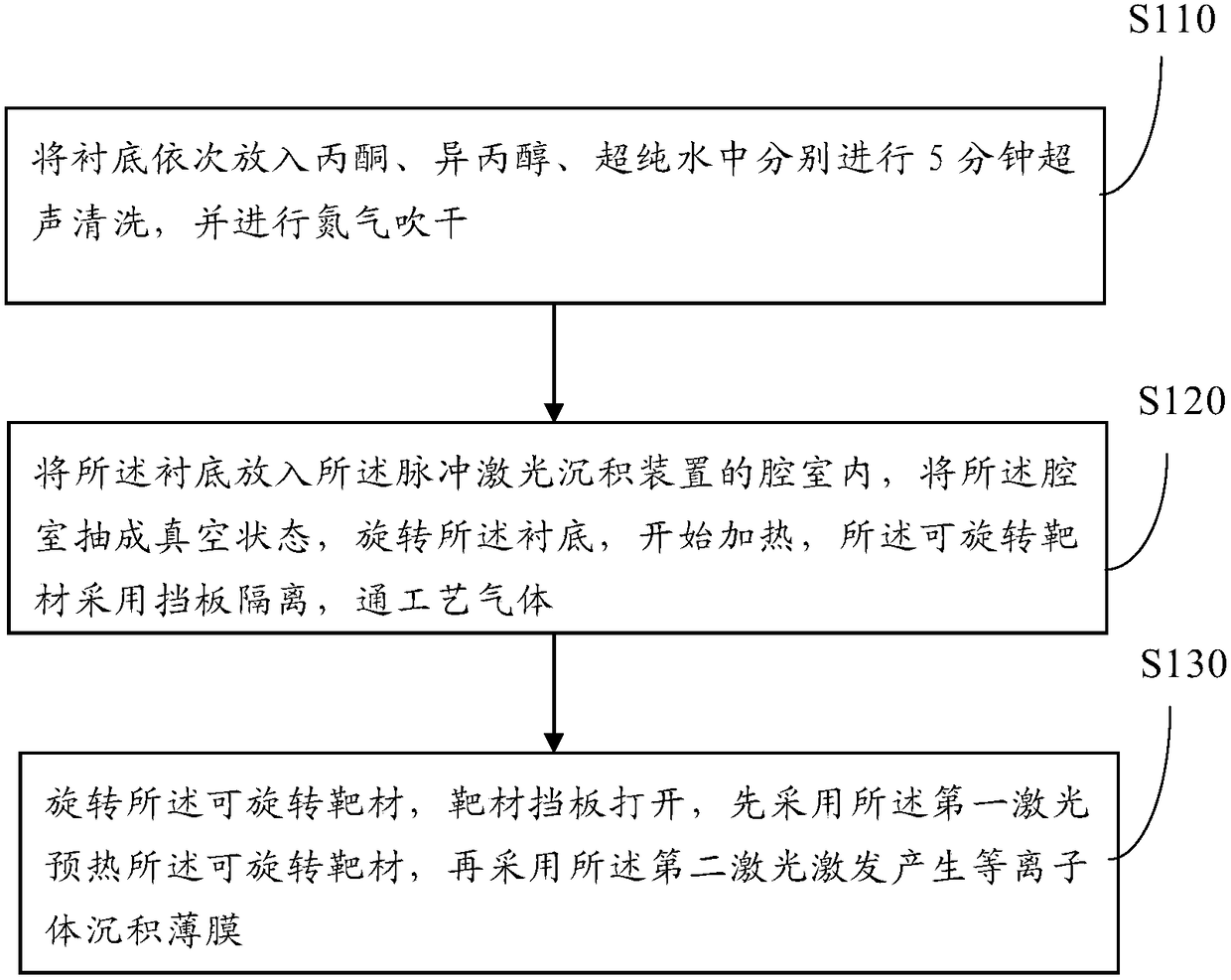

[0038] The embodiment of the present application also provides a pulsed laser deposition method, such as figure 2 as shown, figure 2 A schematic flow chart of a pulsed laser deposition method provided in an embodiment of the present application, the method includes:

[0039] Step 110: Put the substrate 6 into acetone, isopropanol, and ultrapure water in turn for 5 minutes of ultrasonic cleaning, and blow dry with nitrogen;

[0040] Step 120: Put the substrate 6 into the chamber 1 of the pulsed laser deposition device, evacuate the chamber 1 into a vacuum state, rotate the substrate 6, start heating, and the rotatable target 5 Use baffles to isolate and pass process gas, the flow rate of the process gas is 0-100 sccm, and the process pressure in the chamber is 10 -4 -10 -8 Pa;

[0041] Step 130: Rotate the rotatable target 5, open the target baffle, first use the first laser 3 to preheat the rotatable target, and then use the second laser 4 to excite to generate a plasma ...

Embodiment 3

[0043] The embodiment of the present application also provides a pulsed laser deposition method, the first laser 3 and the second laser 4 are incident on the upper surface of the rotatable target 5 through the same quartz window 2, and the method includes:

[0044] Step 110: Put the substrate 6 into acetone, isopropanol, and ultrapure water in turn for 5 minutes of ultrasonic cleaning, and blow dry with nitrogen;

[0045] Step 120: Put the substrate 6 into the chamber 1 of the pulsed laser deposition device, evacuate the chamber 1 into a vacuum state, rotate the substrate 6, start heating, and the rotatable target 5 Use baffles to isolate and pass process gas, the flow rate of the process gas is 0-100 sccm, and the process pressure in the chamber is 10 -4 -10 -8 Pa;

[0046] Step 130: Rotate the rotatable target 5, open the target baffle, first use the first laser 3 to incident on the upper surface of the rotatable target 5 through the quartz window 2a, preheat the rotatable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com