Preparation method of Ta-based high-temperature protection coating with self-healing function

A protective coating, self-healing technology, applied in the coating, metal material coating process, vacuum evaporation plating and other directions, can solve the problems of expensive materials, poor high temperature wear resistance, easy to fall off, etc., to achieve high bonding strength , The effect of improving the bonding strength and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Pretreatment of the substrate material. Select a #45 steel disc with a diameter of 45mm and a thickness of 1.5mm as the substrate, and use #25#200#400#600#800 sandpaper to polish and remove the rust layer and oxide layer on the surface. Polished. The obtained substrate was ultrasonically cleaned with acetone and alcohol successively, and then dried with nitrogen to obtain a clean and mirror-surfaced substrate.

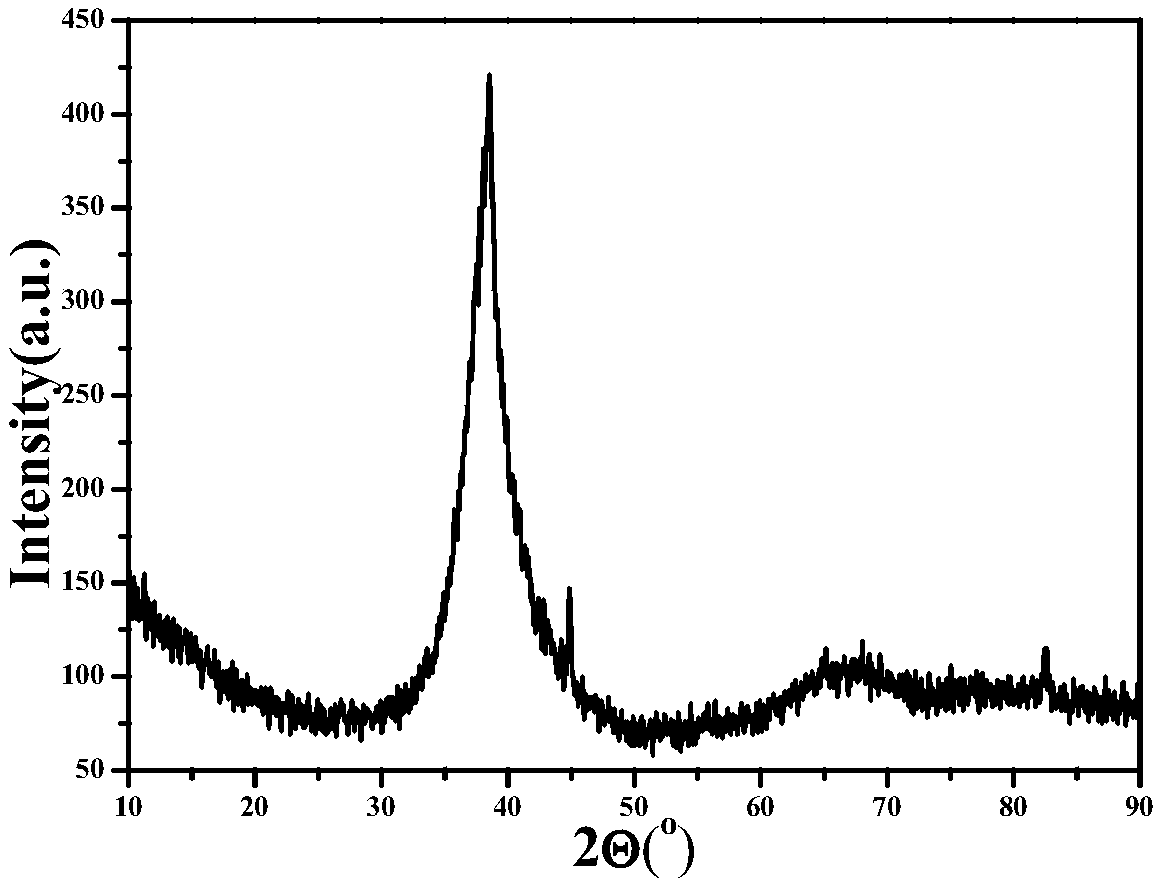

[0026] Step 2: Preparation of the middle layer of the metal Ta film: high-purity Ta (99.99%) is used as the target material for the experiment, and the Ta film is pre-sputtered on the surface of the substrate by DC magnetron sputtering, and the process parameters are: background vacuum 5 *10 -3 Pa, the working pressure is 0.6Pa, the sputtering power is 60W, the Ar flow rate is 25sccm, and the sputtering time parameter is controlled to obtain a Ta film transition layer with a thickness of 500nm-2um.

[0027] Step 3: Preparation of Ta-Ag self-healing hig...

Embodiment 2

[0031] The pretreatment of the substrate material in step 1 is the same as step 1 of the embodiment.

[0032] Step 2: Preparation of the middle layer of the metal Ta film: high-purity Ta (99.99%) is used as the target material for the experiment, and the Ta film is pre-sputtered on the surface of the substrate by DC magnetron sputtering, and the process parameters are: background vacuum 5 *10 -3 Pa, the working pressure is 0.4Pa, the Ta sputtering power is 70W, the Ar flow rate is 25sccm, and the sputtering time parameters are controlled to obtain a Ta film transition layer of 500-2um.

[0033] Step 3: Preparation of Ta-Ag self-healing high-temperature protective coating; on the substrate containing the Ta interlayer obtained after step 2, the purchased high-purity Ag target and the Ta target used in step 2 are used Composite magnetron sputtering is carried out, and Ta and Ag are sputtered and deposited on the surface at the same time by DC magnetron sputtering method, so as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com