A flexible interpenetrating network porous material that can be used for molding and its preparation method

A technology of interpenetrating network and porous material, which is applied in the field of flexible interpenetrating network porous material that can be used for molding and its preparation, and can solve the problem of non-reusable polymer materials for thermosetting resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

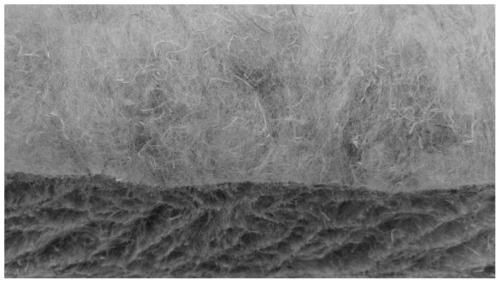

Image

Examples

preparation example Construction

[0032] Describe in detail the preparation method of the flexible interpenetrating network porous material that can be used for molding in the present invention, and its main steps are as follows:

[0033] 1) Fiber extraction process: pulping wood, branch wood, small-diameter wood, etc. to obtain wood fiber; removing green and knots from 1-3 year old bamboo, soaking it in slaked lime solution, and taking out the bamboo slices after softening, beating, Rinse, roll with a rolling machine multiple times, comb to remove parenchyma, and finally obtain long bamboo fiber bundles, the length of which is 50mm-100mm; the moisture content of the two fibers is below 15wt.%.

[0034] Wherein, the slaked lime solution is a solution formed by dissolving quicklime in water, reacting and slaking, and the soaking time is 1 day to 2 months. Preferably, the mass ratio of quicklime to water is 1:9-6:4.

[0035] 2) The preparation process of the interpenetrating network fiber mat: loosen and disper...

Embodiment 1

[0040] Preparation of raw materials: pulp wood, branch wood, small-diameter wood, etc. to make wood fiber; remove green and knots from 1-3 year old bamboo, soak in slaked lime solution, and after the bamboo slices soften, take them out, beat them, wash them, and grind them. The press is pressed several times, the parenchyma is removed by carding, and finally long bamboo fiber bundles are obtained, and the length of the bamboo fiber bundles is 50mm-100mm; the moisture content of the two fibers is below 15wt.%.

[0041] Open the bamboo fiber and polypropylene fiber, and then mix the three fibers according to the mass ratio of wood fiber, bamboo fiber and polypropylene fiber at a ratio of 10%: 40%: 50%, pave, and crochet needles to form a flexible interpenetration Network porous material, the density of needle punching is required to be 50 thorns / cm 2 , the areal density of the flexible porous material obtained by acupuncture is 2200g / m 2 .

[0042] Then put the porous material...

Embodiment 2

[0044] The preparation of raw materials is the same as in Example 1.

[0045] Open the bamboo fiber and polypropylene fiber, and then mix the three fibers according to the mass ratio of wood fiber, bamboo fiber and polypropylene fiber at a ratio of 15%: 35%: 50%, pave, and crochet needles to form a flexible interpenetration Network porous material, the density of needle punching is required to be 50 thorns / cm 2 , the areal density of the flexible porous material obtained by acupuncture is 2200g / m 2 .

[0046] Then put the porous material into a molding machine for pre-compression at a temperature of 200°C for 2 minutes, then put the flexible material into a mold and cold-press to shape it to prepare a composite material for vehicles. The surface of the composite material is smooth and dense, and the static bending strength is 48MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com