Method for dyeing seaweed fiber with polycarboxylic acid dye

A seaweed fiber and polycarboxylic acid technology, applied in the field of fiber dyeing, can solve the problems of large loss of strength, low coloring rate, and few types of dyes, etc., and achieve the effect of bright color, uniform color and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

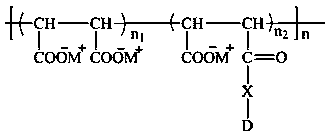

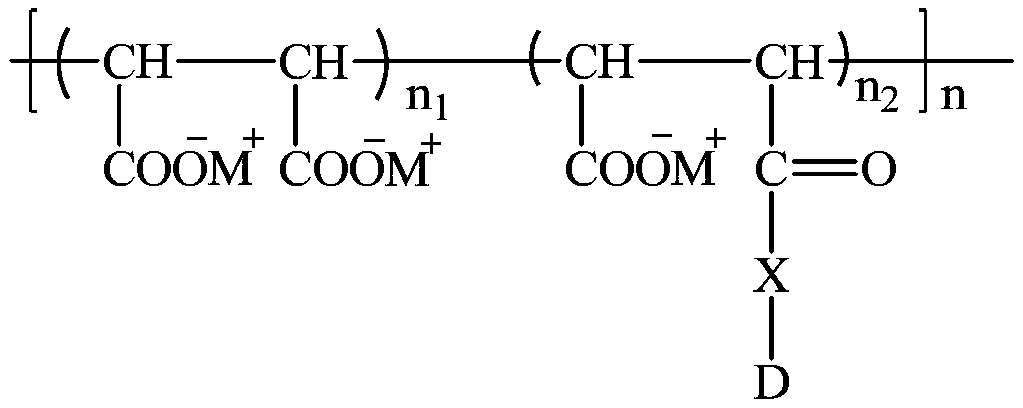

[0033] The method for dyeing seaweed fibers with polycarboxylic acid dyes is to use metal ions as connectors, and form complex bonds with metal ions and seaweed fibers and polycarboxylic acid dyes to realize the effect of polycarboxylic acid dyes on seaweed fibers. Stained. The structural formula of the polycarboxylic acid dye DY-1 is:

[0034]

[0035] where: n 1 =10-15, n 2 =10-15, n=80-100.

[0036] The method of described polycarboxylic acid dye dyeing seaweed fiber is as follows:

[0037] Dissolve 0.5g of the polycarboxylic acid dye in 400g of water, add 1% hydrochloric acid solution to adjust the pH value to 4.5, then add 0.3g of tin sulfate, mix well to obtain a dye solution; then add 30g of seaweed fiber to the dye solution at 60°C After dyeing, take out the seaweed fiber and soak it in 4‰ neutral soap solution at 95°C for 10 minutes. Finally, wash the seaweed fiber fully and dry it in the air.

Embodiment 2

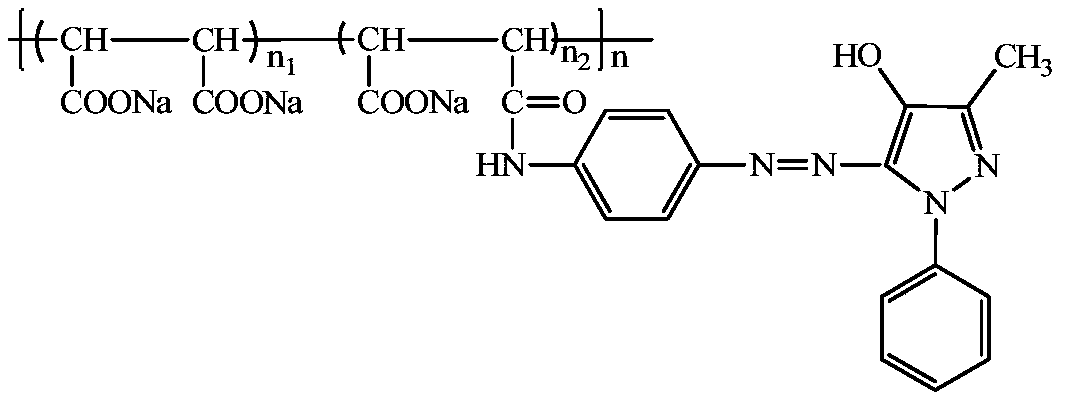

[0039] The method for dyeing seaweed fibers with polycarboxylic acid dyes is to use metal ions as connectors, and form complex bonds with metal ions and seaweed fibers and polycarboxylic acid dyes to realize the effect of polycarboxylic acid dyes on seaweed fibers. Stained. The structural formula of the polycarboxylic acid dye DY-2 is:

[0040]

[0041] where: n 1 =5-8, n 2 =5-8, n=100-150.

[0042] The method of described polycarboxylic acid dye dyeing seaweed fiber is as follows:

[0043] Dissolve 1.5g of the polycarboxylic acid dye in 600g of water, add 1% ammonia solution to adjust the pH value to 6.5, then add 1g of chromium sulfate, mix well to obtain a dye solution; then add 30g of seaweed fiber to the dye solution at 70°C Dyeing for 40 minutes. After dyeing, take out the seaweed fiber, soak it in 2‰ neutral soap solution at 90°C for 15 minutes, and finally wash the seaweed fiber fully and dry it in the air.

Embodiment 3

[0045] The method for dyeing seaweed fibers with polycarboxylic acid dyes is to use metal ions as connectors, and form complex bonds with metal ions and seaweed fibers and polycarboxylic acid dyes to realize the effect of polycarboxylic acid dyes on seaweed fibers. Stained. The structural formula of the polycarboxylic acid dye DY-3 is:

[0046]

[0047] where: n 1 =20-25, n 2 =20-25, n=400-500.

[0048] The method of described polycarboxylic acid dye dyeing seaweed fiber is as follows:

[0049] Dissolve 2g of the polycarboxylic acid dye in 500g of water, add 1% ammonia solution to adjust the pH to 7.0, then add 1.2g of copper chloride, mix well to obtain a dye solution; then add 30g of seaweed fiber to the dye solution at 80°C Dyeing for 50 minutes, after the dyeing, take out the seaweed fiber, soak it in 4‰ neutral soap solution and boil it at 92°C for 14 minutes, and finally wash the seaweed fiber fully and dry it in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com