Preparation method of printed display device

A printing display and device technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc. Effect of improving surface tension and spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

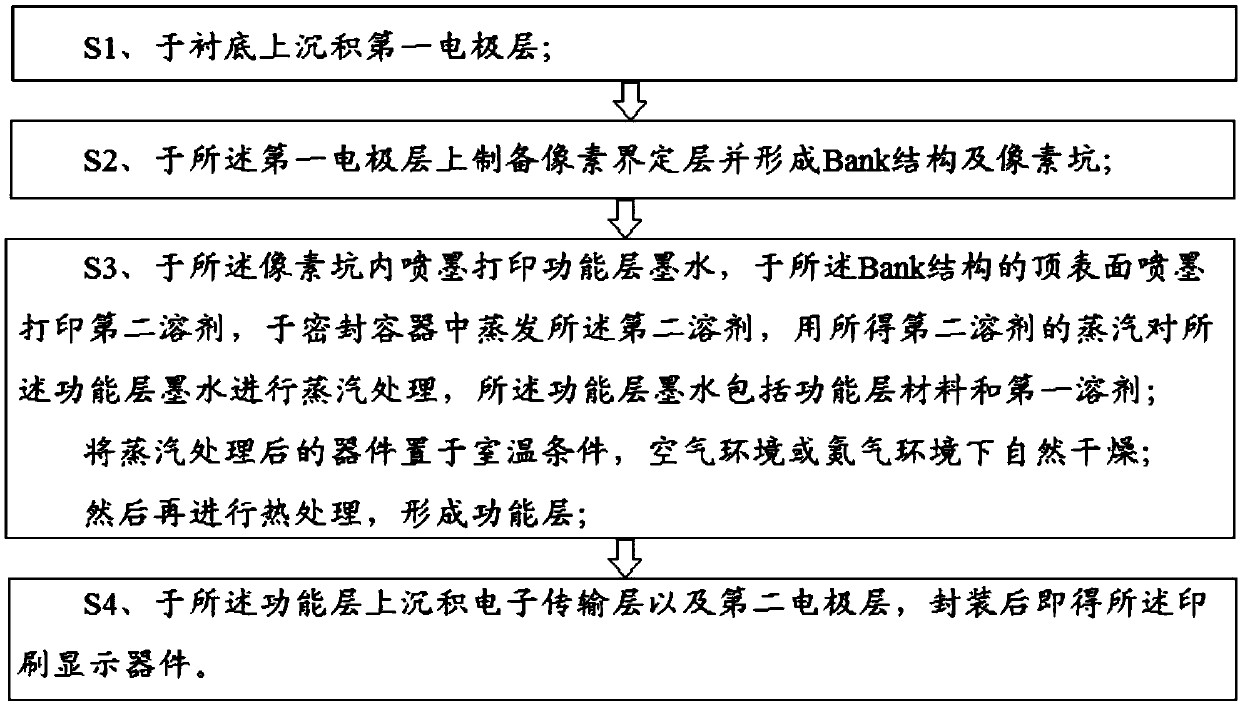

[0039] See image 3 , a method for preparing a printed display device in this embodiment, comprising the following steps:

[0040] S1. Depositing a first electrode layer on the substrate;

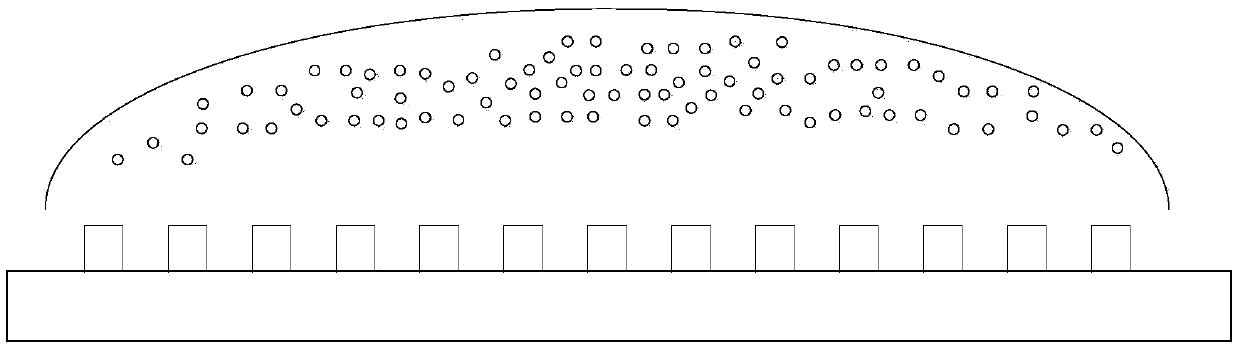

[0041] S2. Prepare a pixel defining layer on the first electrode layer and form a Bank structure and a pixel pit; the pixel defining layer in this embodiment has a liquid-repellent property, and it is not necessary to carry out hydrophilic treatment on the structure of the pixel defining layer to ensure that Film formation uniformity;

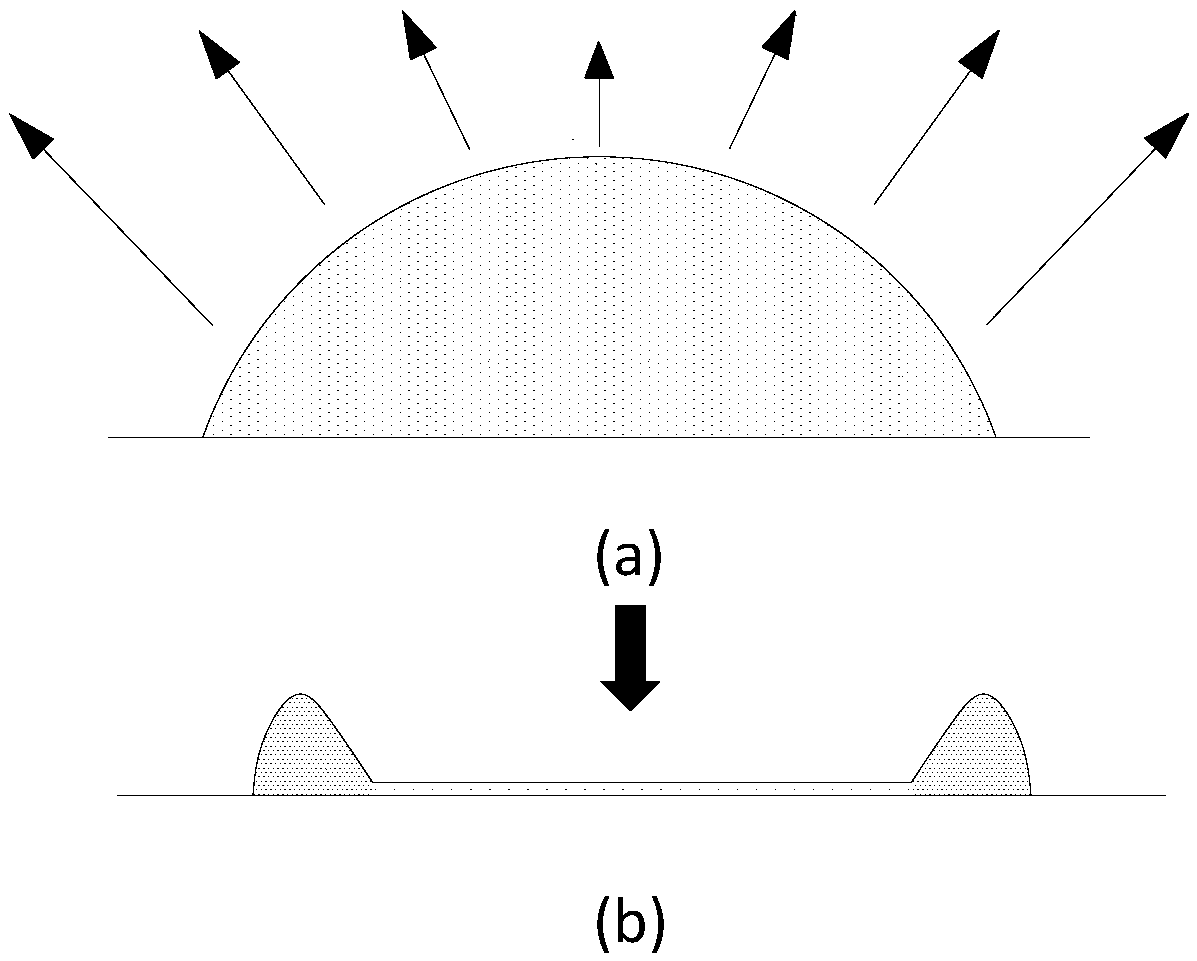

[0042] S3. Inkjet print the functional layer ink in the pixel pit, inkjet print the second solvent on the top surface of the Bank structure, evaporate the second solvent in a sealed container, and use the vapor of the obtained second solvent to treat the functional layer. A layer of ink is subjected to steam treatment, and the functional layer ink includes a functional layer material and a first solvent;

[0043] Place the steam-treated device at room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com